Why Precision Machining Is Essential for Modern Robotics

TL;DR

Precision machining is a critical manufacturing process that enables the creation of high-accuracy components essential for modern robotics. By utilizing techniques like Computer Numerical Control (CNC), it produces parts with extremely tight tolerances, which is fundamental to a robot's performance, reliability, and efficiency. This synergy drives advancements in automation, allowing robots to perform complex tasks with remarkable consistency and accuracy.

Defining the Core Concepts: Precision Machining and Robotics

At its core, precision machining is a manufacturing process where material is removed from a workpiece to create a finished part that meets highly exact specifications. The defining characteristic is the adherence to extremely tight tolerances, often measured in microns. This is typically achieved using CNC machines, which translate digital designs from Computer-Aided Design (CAD) software into precise movements of cutting tools. This process is fundamental to creating the intricate, reliable components that power advanced technology.

When applied to robotics, this concept branches into two key areas. The first is the manufacturing of robotic components themselves. Robots are complex assemblies of joints, gears, and structural parts, each requiring flawless production to ensure smooth, predictable movement. The second is the practice of "robotic machining," where an industrial robot arm is equipped with a machining tool, such as a spindle. As noted by industry experts at RoboDK, this approach offers greater flexibility and a larger work envelope compared to traditional CNC machines, making it ideal for large or complex parts.

Understanding the terminology is also crucial. In robotics, "precision" and "accuracy" have distinct meanings. Accuracy refers to a robot's ability to reach a specific point in space. Precision, more accurately termed repeatability, is the robot's ability to return to that same point consistently over multiple attempts. High repeatability is a direct result of well-machined components that minimize variance and wear, ensuring a robot can perform its programmed tasks reliably time after time.

Key Benefits of Integrating Robotics in Precision Machining

The convergence of robotics and precision machining has unlocked significant advantages for manufacturers, pushing the boundaries of what's possible in terms of quality, speed, and complexity. These benefits stem from the inherent strengths of automation and the exacting nature of precision manufacturing processes.

Enhanced Accuracy and Repeatability

Perhaps the most significant benefit is the dramatic improvement in consistency. Robotic systems can execute tasks with micron-level accuracy, eliminating the potential for human error and fatigue. This leads to higher-quality parts with minimal deviation from the design specifications. As detailed by Hexagon Machine, this level of accuracy is crucial in robotics, where even the smallest error can have a significant impact on a robot's performance. The result is a more reliable end product and a reduction in rework, saving both time and resources.

Increased Efficiency and Cost Savings

Automation drives efficiency. Robots can operate 24/7 without breaks, significantly accelerating production cycles and reducing downtime. They can perform repetitive tasks like loading and unloading materials, tool changes, and part inspection faster and more consistently than human operators. This continuous operation leads to higher throughput and allows manufacturers to meet growing demands more effectively. Over time, these efficiency gains translate into substantial cost savings, making advanced manufacturing more accessible.

Flexibility for Complex Geometries

Modern product design often involves intricate shapes and complex geometries that are challenging or impossible to produce with traditional methods. The integration of multi-axis robotic arms enables the machining of these complex designs with unparalleled agility. This capability, highlighted by Arrow Automotive, opens new possibilities for innovation, allowing engineers to design parts that are optimized for performance rather than being limited by manufacturing constraints. This flexibility is invaluable in industries like aerospace and medical devices, where custom, high-performance components are standard. For companies needing to produce such complex parts with tight tolerances, specialized services are essential. For instance, providers like XTJ offer advanced 4 and 5-axis CNC machining for rapid prototyping and volume production across a wide range of materials.

Essential Applications: From Joints to End-of-Arm Tooling

Precision machining is not an abstract concept in robotics; it is the tangible process behind nearly every critical component that allows a robot to function. The performance of a robotic system is a direct reflection of the quality of its individual parts, which must be manufactured to exacting standards to work together seamlessly.

The applications of precision machining are extensive and cover the entire anatomy of a robot. According to an analysis by Fictiv, some of the most common and critical components produced through CNC machining include:

- Structural Components: This category includes the core framework of the robot, such as joints (shoulder, elbow, wrist), housings, and specialized brackets. These parts require high strength and rigidity to support the robot's weight and withstand operational forces, and they must be machined precisely to ensure proper alignment.

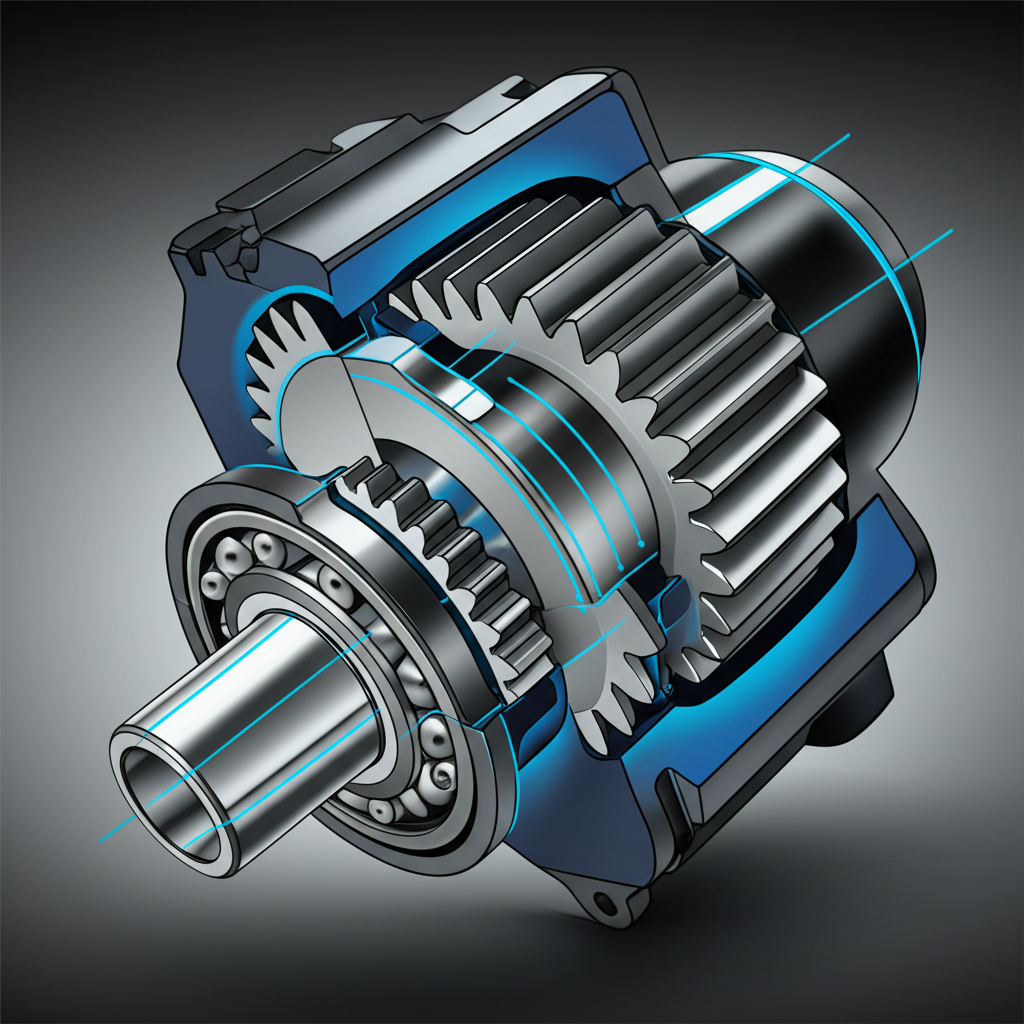

- Gears and Bearings: Essential for transferring motion and reducing friction, gears and bearings are intricate components that demand some of the tightest tolerances. Any imperfection can lead to inefficient movement, increased wear, and premature failure of the robotic system.

- Shafts and Fasteners: Though seemingly simple, shafts that transmit power and custom fasteners that hold the assembly together must be machined perfectly to prevent vibration and ensure a secure fit.

- End-of-Arm Tooling (EOAT): Also known as end effectors, these are the tools a robot uses to interact with its environment, such as grippers, welders, or drills. EOAT is often highly customized for specific tasks and must be both lightweight and durable, making precision machining the ideal manufacturing method to achieve this balance.

- Custom Fixtures and Jigs: To perform tasks, robots often rely on fixtures to hold parts in a precise and repeatable location. These fixtures are typically one-off, custom parts that are perfectly suited for CNC machining, which allows for quick turnaround of high-precision, custom designs.

The Future of Manufacturing: Trends in Robotic Machining

The synergy between precision machining and robotics is not static; it is a rapidly evolving field that continues to shape the future of manufacturing. As technology advances, several key trends are emerging that promise to further enhance the capabilities, efficiency, and accessibility of automated production systems. These developments are blurring the lines between traditional CNC machines and more flexible robotic solutions.

One of the most significant trends is the rise of collaborative robots, or "cobots." Unlike traditional industrial robots that operate in isolated cells, cobots are designed to work safely alongside human operators. In a machining environment, they can assist with tasks like machine tending, quality control, and finishing processes, enhancing productivity without requiring a complete overhaul of the workspace. This collaborative approach combines human ingenuity with robotic consistency.

Furthermore, the integration of Artificial Intelligence (AI) and Machine Learning (ML) is making robotic systems smarter and more adaptive. AI algorithms can optimize tool paths in real time, predict when a cutting tool is wearing down and needs replacement, and adjust for minor variations in material or environmental conditions. This data-driven approach leads to a more dynamic and resilient machining process, reducing unplanned downtime and continuously improving efficiency over time.

Finally, the ongoing advancements in sensor technology and offline programming are making robotic machining more precise and easier to implement. Improved sensors provide real-time feedback to compensate for micro-vibrations or tool deflection, while advanced software allows complex machining programs to be generated and simulated offline. This reduces setup time and makes it easier for manufacturers to transition from traditional CNC to more flexible robotic platforms, paving the way for a more automated and intelligent future in manufacturing.

Frequently Asked Questions

1. What is robotic machining?

Robotic machining is a manufacturing process that uses a multi-axis industrial robot arm, equipped with a machining spindle or other cutting tool, to remove material from a workpiece. Unlike traditional CNC machines, which have a fixed work area, robots offer a larger operational range and greater flexibility to machine complex shapes and large parts. It is valued for its cost-effectiveness and adaptability in applications like prototyping, trimming, and light milling.

2. Who are the big 4 in the industrial robotics industry?

While the market is dynamic, the industrial robotics industry has historically been dominated by a few key players. Based on market share data, the "big four" have often been cited as FANUC (Japan), ABB (Switzerland), Yaskawa (Japan), and KUKA (Germany). However, other significant manufacturers like Epson and Kawasaki also hold substantial market shares, particularly in specific regions or applications.

3. What is precision in robotics?

In the context of robotics, "precision" most commonly refers to a robot's repeatability—its ability to consistently return to the same point over and over again. This is different from accuracy, which is the ability to move to a commanded position in space. High precision (or repeatability) is crucial for tasks that require consistent actions, such as welding, assembly, or machine tending, as it ensures the robot performs the task identically every time.

-

Posted in

automation, cnc machining, manufacturing, precision machining, robotics