Grade 5 Titanium Ti‑6Al‑4V Explained: Properties To Practice

What Is Grade 5 Titanium?

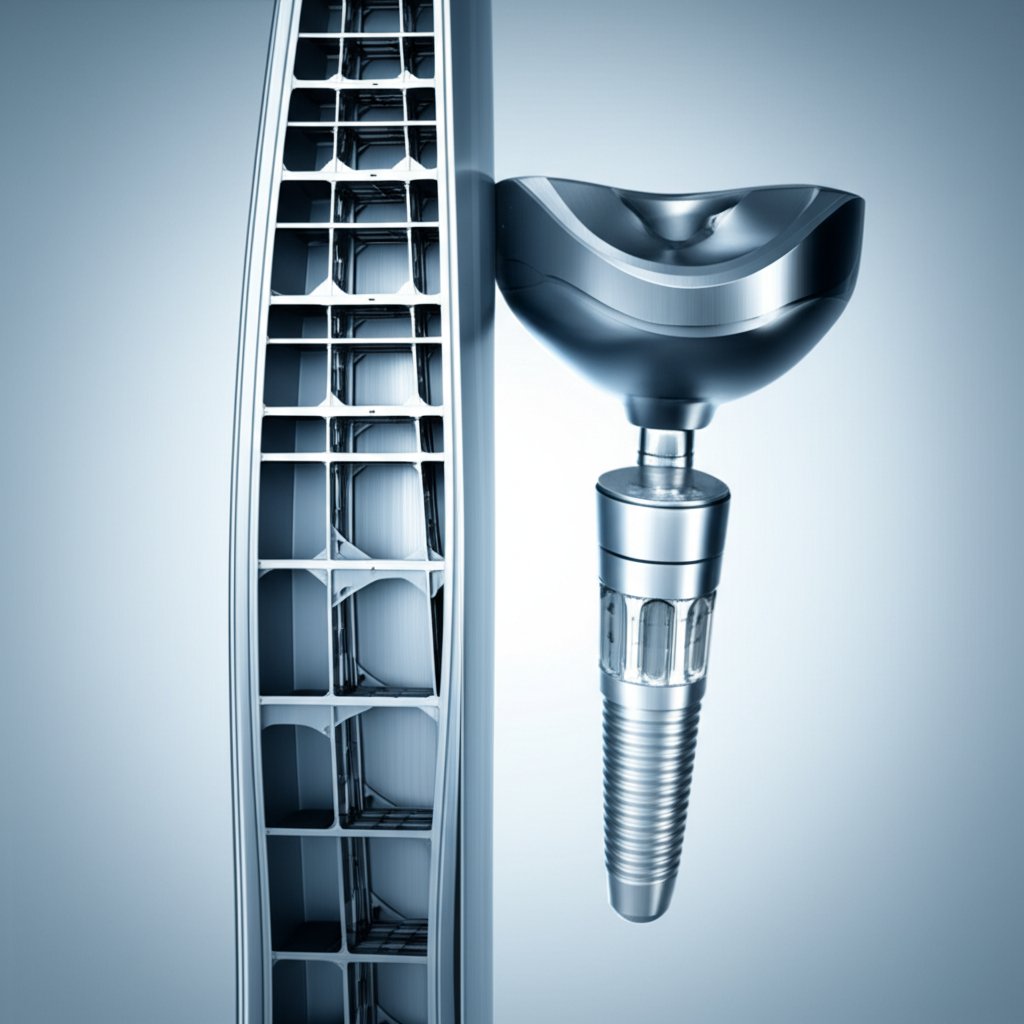

Ever wondered why grade 5 titanium seems to show up everywhere from jet engines to surgical implants? When engineers talk about titanium grades, one name always stands out: Ti-6Al-4V. But what is grade 5 titanium, and why does it dominate so many critical applications?

Understanding Ti-6Al-4V and Common Designations

At its core, grade 5 titanium is an alpha-beta titanium alloy—meaning it contains a mix of two different crystal structures, stabilized by a specific blend of alloying elements. In industry, you’ll hear it called by several names, depending on region, product form, or standard:

- Ti-6Al-4V (or Ti 6Al 4V) – the most common technical designation, reflecting its main alloying elements

- Grade 5 – ASTM grade name used in standards and procurement

- Ti64 – a shorthand often used in aerospace and additive manufacturing

- AMS 4911 – specification for sheet and plate forms

- TC4 – the designation under the Chinese national standard (GB/T), which is functionally equivalent to Grade 5.

- ELI (Extra Low Interstitials) – a variant with enhanced toughness for medical applications

So, when you see any of these terms, they’re usually referring to the same fundamental alloy—just filtered through different industry lenses or product standards. For example, Wikipedia confirms that Ti-6Al-4V, Grade 5, Ti64, and TC4 all point to this versatile material.

Grade 5 titanium’s unique value lies in its exceptional strength-to-weight ratio and corrosion resistance, making it the workhorse for demanding environments from aerospace to medical implants.

Where Grade 5 Fits Among Titanium Grades

Within the family of titanium grades, grade 5 sits at the intersection of high strength, moderate ductility, and good processability. Unlike commercially pure grades (like Grade 2), Ti-6Al-4V offers a dramatic leap in mechanical performance, while still maintaining the hallmark corrosion resistance of titanium alloys. It’s an alpha-beta alloy, which means it can be heat treated for further property tuning—something pure grades can’t match as easily.

In practice, you’ll find titanium grade 5 in:

- Aerospace structures and engine components

- Medical implants and surgical tools

- Energy and offshore hardware

- High-performance automotive and sporting goods

- Consumer electronics and additive manufacturing builds

Each sector may use a slightly different name or specification, but the underlying alloy is the same. If you’re sourcing ti grade 5 for a project, always check the relevant standard—like AMS 4911 for sheet and plate—or confirm with your supplier to ensure equivalency.

Key Takeaways for Engineers

- Grade 5 titanium (Ti-6Al-4V) is the most widely used titanium alloy globally, prized for its balance of strength, weight, and corrosion resistance.

- It’s known by several names: Ti-6Al-4V, Grade 5, Ti64, AMS 4911, TC4, and ELI (for medical variants).

- It’s the go-to choice for applications where failure is not an option—think aircraft, implants, and critical energy systems.

- Understanding the different titanium grades and their designations is essential for correct material selection, certification, and compliance.

Curious how grade 5 stacks up against other titanium grades? See the comparison section for side-by-side grade data. Ready to design or fabricate? Jump to fabrication sections for step-by-step checklists covering forming, machining, and welding.

By the end of this guide, you’ll not only know what is grade 5 titanium, but also when and why to choose it for your toughest engineering challenges. Next, we’ll dive deeper into its physical and mechanical properties—and what makes 6al-4v the industry standard for performance under pressure.

Physical and Mechanical Behavior That Guides Ti-6Al-4V Design Choices

When you’re engineering with grade 5 titanium, understanding its physical and mechanical properties is more than just checking a datasheet. These characteristics shape everything from weight-critical aerospace frames to robust medical implants. So, what makes Ti-6Al-4V stand out, and how do properties like density, modulus, and thermal conductivity of titanium actually impact your design decisions?

Density and Its Impact on Weight-Sensitive Designs

Imagine you’re designing an aircraft component or a racing bike frame. Every gram counts. The density of titanium—specifically for grade 5—is around 4.43 g/cm³, as confirmed by ASM MatWeb. That’s about 60% of the density of steel, but with comparable strength. This low density is why Ti6Al4V is a favorite in mass-critical applications: you get high strength without the weight penalty.

Melting Point and High-Temperature Considerations

Ever wondered how titanium alloys hold up in jet engines or under the hood? Ti-6Al-4V has a melting point in the range of 1604–1660°C (2920–3020°F). This high melting point allows the alloy to retain strength at elevated temperatures, making it reliable for critical, high-heat environments. However, designers should still check the maximum service temperature for their specific application, as performance can drop before reaching the melting point.

Strength, Modulus, and Hardness in Context

Strength is where titanium tensile strength and titanium hardness come into play. Ti-6Al-4V typically offers ultimate tensile strengths in the 900–1200 MPa range, depending on form and heat treatment [AZoM]. For context, this rivals many hardened steels but with much less mass. Hardness values (Rockwell C ~36) mean it resists deformation and wear, though not to the extent of tool steels. If you’re selecting for wear resistance, surface treatments may be necessary since titanium can gall or seize in sliding contact.

The modulus of elasticity for titanium (Young’s modulus) sits around 110–120 GPa for Ti-6Al-4V. This is roughly half that of steel, so titanium components can flex more under load. For stiffness-driven designs—think structural beams or shafts—this means you may need to increase cross-section or use clever geometry. The trade-off? You still save weight and gain corrosion resistance.

Thermal Conductivity and Heat Management

Ever tried machining titanium and noticed the heat builds up fast? That’s because the thermal conductivity of titanium is relatively low—about 6.7–7.3 W/m·K for grade 5 [ASM MatWeb]. This property keeps heat localized during cutting or forming, which can lead to tool wear or thermal distortion if not managed. For product designers, this means careful consideration of heat paths and cooling is crucial—whether in manufacturing or in-service thermal management.

| Property | Typical Range/Note | Design Relevance |

|---|---|---|

| Density | ~4.43 g/cm³ (per AMS/ASM datasheets) | Critical for weight-sensitive parts |

| Melting Point | 1604–1660°C (datasheet range) | Supports high-temperature service |

| Tensile Strength | 900–1200 MPa (form/heat treatment dependent) | Load-bearing and safety-critical components |

| Modulus of Elasticity | 110–120 GPa | Determines stiffness, impacts deflection |

| Hardness | Rockwell C ~36 | Wear resistance, galling risk |

| Thermal Conductivity | 6.7–7.3 W/m·K | Heat management in machining/service |

Ti‑6Al‑4V’s combination of low density and high strength underpins its use in aerospace structures.

- Density of titanium means you get more strength per unit weight versus most metals.

- Thermal conductivity of titanium must be considered in both design and manufacturing for optimal performance.

- The modulus of elasticity for titanium affects how much a part will flex under load—plan geometry accordingly.

- Always confirm titanium hardness and titanium tensile strength for your specific product form and standard.

In summary, the unique blend of properties in Ti6Al4V allows engineers to balance lightness, strength, and durability in ways that few other alloys can match. Next, we’ll compare how grade 5 stacks up against other titanium grades—helping you choose the right alloy for your project’s needs.

Choosing the Right Titanium Grade

When you’re faced with a choice between grade 5 titanium and other grades, it’s easy to feel overwhelmed. Sounds complex? Let’s break down the differences so you can match your project’s needs to the right alloy—whether you’re considering grade 2 vs grade 5 titanium, looking at ELI for implants, or wondering about TC4 in a global supply chain.

Choosing Between Common Titanium Grades

Think of titanium grades as a toolbox: each has its own set of strengths and tradeoffs. Here’s a quick overview of how the most common types stack up:

| Grade | Typical Properties | Weldability | Formability | Common Product Forms | Typical Standards |

|---|---|---|---|---|---|

| Grade 5 (Ti-6Al-4V) | High strength, good corrosion resistance, moderate ductility | Good (with matching or ELI filler) | Limited (hot forming preferred) | Bar, plate, sheet (AMS 4911), forgings, tube | AMS 4911, ASTM B265 |

| Grade 5 ELI (Ti-6Al-4V ELI) | Similar to Grade 5, but with extra low interstitials for improved toughness and biocompatibility | Good | Limited | Bar, rod, wire, medical implants | ASTM F136 |

| Grade 2 | Lower strength, excellent corrosion resistance, high ductility | Excellent | Excellent (cold forming, deep drawing) | Sheet, plate, tube, pipe | ASTM B265 |

| Grade 9 (Ti-3Al-2.5V) | Medium strength, good corrosion resistance, good ductility | Good | Good (especially for tube forming) | Tube, pipe, sheet | ASTM B338 |

| TC4 (China GB) | Equivalent to Grade 5/Ti-6Al-4V; high strength, corrosion resistance | Good | Limited | Bar, plate, powder (AM) | GB/T 3620.1 |

Why Engineers Pick Grade 5 Over Grade 2 or Grade 9

If you’re comparing grade 2 titanium vs grade 5, the answer often comes down to strength. Grade 5 (Ti-6Al-4V) offers a much higher strength-to-weight ratio than Grade 2, making it ideal for aerospace, automotive, and high-performance applications. However, this extra strength comes at the cost of formability—Grade 2 is far easier to cold form and weld, making it the workhorse for chemical processing and marine environments where corrosion resistance and ease of fabrication are critical.

Grade 9 (Ti-3Al-2.5V) sits in the middle: it’s often chosen for tubing that needs moderate strength and good cold workability, such as bicycle frames or heat exchanger coils. If your project needs a balance between formability and performance, Grade 9 is worth considering.

Understanding ELI Variants and TC4 References

What about ti-6al-4v eli? The ELI (Extra Low Interstitials) variant of Grade 5 is engineered for improved fracture toughness and biocompatibility. That’s why it’s the top pick for critical medical implants like hip replacements or dental posts. If your application involves direct contact with body tissue or demands the highest toughness, ELI is the go-to.

And if you come across tc4 titanium in specifications or supplier catalogs, know that it’s essentially another name for Grade 5, commonly used in China and some Asian markets. Both TC4 and Grade 5 share the same chemical composition and properties, but always verify standards equivalence before substituting one for the other.

Design Tradeoffs to Consider

Still not sure which grade to choose? Here’s a quick decision tip:

- Prioritize strength and high-performance? Choose Grade 5 or TC4.

- Need easy forming or welding? Grade 2 is your best bet.

- Looking for a balance for tubular forms? Grade 9 offers a middle ground.

- Critical biocompatibility or fracture toughness? Go with Ti-6Al-4V ELI.

For a full understanding of the landscape, it helps to have titanium grades explained in context. Each grade has its sweet spot—matching the alloy to your dominant requirement (strength, formability, or biocompatibility) is the key to success. And if you’re ever in doubt, always check certifications and standards for your application, especially when working with international suppliers or considering different grades of titanium.

Choosing the right titanium grade is about balancing performance, processability, and cost—always verify your material’s certification and suitability for the end use.

Next, we’ll move from material selection to fabrication—exploring the forming and cold-work techniques that help you get the most out of Ti-6Al-4V and its relatives, including insights for working with titanium grade 4 and other specialty alloys.

Forming and Cold Work Practices That Actually Help

Cold Forming Capabilities of Ti‑6Al‑4V

When you first try to bend or shape a ti 6al 4v titanium sheet, you’ll notice it behaves differently from softer metals. Sounds complex? The challenge comes down to two key traits: high strength and notable springback. Unlike commercially pure grades, 6al4v titanium offers limited ductility at room temperature, so cold forming is best reserved for simple bends or shallow draws in thinner sheets. For more severe shapes or thicker material, warm or hot forming is usually needed to avoid cracking and excessive work hardening [ASM Handbook].

Managing Springback and Minimum Bend Radii

Ever bent a ti sheet and found it didn’t hold the angle you expected? That’s springback in action—a direct result of titanium’s lower modulus of elasticity. For titanium 6al-4v, you must plan for a significant loss in included bend angle after forming, sometimes as much as 15–25 degrees at room temperature. The higher the alloy’s strength, the greater the springback, so compensation is essential in tool design. Overbending and using larger radii than you would for steel or aluminum are standard practices. For exact minimum bend radii, always consult the product’s ASTM or AMS specification, such as ASTM B265 for titanium sheets, or refer to OEM forming manuals for your application.

- Tool radii selection: Use generous bend radii—often several times the sheet thickness for ti 6 4 alloys. Validate with current standards.

- Incremental forming passes: For complex shapes, break the operation into multiple passes to avoid cracking and distribute strain.

- Springback compensation: Design dies to overbend, and verify with trial runs on scrap or prototype sheets.

- Lubrication choices: Apply dry-film lubricants or those containing anti-galling agents (e.g., PTFE, molybdenum disulfide), as recommended for titanium forming.

- Surface film protection: Keep sheets free from scratches, gouges, or contamination; clean and deburr all edges before forming.

- Inspection checkpoints: Check for cracks, edge splits, and surface galling after each pass; document results to refine future setups.

- Note: Always validate numeric bend radii with your specific product-form specification or OEM forming manual before production.

Plan for significant springback in Ti‑6Al‑4V—build compensation into tooling and verify with trial bends.

Stretch Forming and Local Heating Guidance

Need to form compound curves or tight radii in a titanium sheet? Stretch forming is possible but requires careful setup. For ti 6al 4v, slow forming speeds and high clamping forces help distribute strain and prevent local thinning or buckling. When cold forming isn’t enough, local heating (600–800°C) can dramatically increase ductility and reduce springback. However, heating must be controlled to avoid oxidation and preserve surface quality—use protective atmospheres or post-forming descaling if needed. Superplastic forming is another advanced option, especially for aerospace-grade ti sheet, enabling complex shapes with minimal residual stress.

Fixtures, Tools, and Surface Protection

Imagine you’re setting up a press brake for a batch of 6al 4v titanium parts. Robust, supportive dies are crucial—titanium’s strength can cause tool deflection, so ensure your fixtures are rigid and well-aligned. Use non-metallic or titanium-coated tooling where possible to minimize galling. Keep all surfaces meticulously clean; even fingerprints or small debris can lead to defects or embrittlement. For high-value parts, consider protective films or strippable coatings during handling and forming.

Documenting each forming trial—recording tool settings, springback compensation, and inspection results—can help you dial in the process for future runs. This is especially important for tight-tolerance applications or when working with new batches of titanium sheets.

Key Takeaways for Ti 6Al 4V Forming Success

- Cold forming of ti 6 4 is possible for simple shapes but limited by ductility and springback; use warm or hot forming for complex geometries.

- Always compensate for springback—overbend and validate with actual trial bends.

- Use proper lubricants and keep all surfaces clean to prevent galling and cracks.

- Choose robust, supportive fixturing and document process parameters for repeatability.

Ready to tackle even more challenging geometries or ultra-thin walls? Next, we’ll explore machining workflows that help you achieve high precision in titanium parts—without sacrificing the properties you’ve worked so hard to preserve during forming.

Machining Workflows That Tame Titanium

Tool Materials, Geometries, and Coatings That Work

Ever started machining grade 5 titanium and noticed your tools wearing out faster than expected? You’re not alone. The low conductivity of titanium means heat builds up rapidly at the cutting edge, leading to rapid tool degradation and poor finishes. To counter this, sharp carbide tools are the industry standard—preferably with advanced coatings like TiAlN or multi-layer PVD, which resist heat and reduce chemical reactivity.

Tool geometry matters just as much. Avoid razor-sharp edges, which can chip; instead, opt for honed or edge-prepped inserts that balance sharpness with durability. For 6al 4v titanium, a positive rake and a robust core help minimize cutting forces and resist work hardening. Chipbreakers are essential—titanium’s stringy chips can wrap around the cutter, so choose geometries that promote short, controllable chips.

Coolant Delivery, Heat Control, and Tool Life

Why does ti64 seem to generate so much heat during machining? It’s all about ti thermal conductivity—which is only a fraction of what you’d find in steel or aluminum. Most of the heat from cutting stays at the tool edge, not in the chip. That’s why high-pressure through-tool coolant is a must. It flushes chips away, cools the cutting zone, and prevents built-up edge formation.

Flood coolant systems work, but for deep pockets or thin-walled ti 64 parts, high-pressure, targeted delivery is far more effective. This not only extends tool life but also helps maintain tight tolerances by controlling thermal expansion. Synthetic or water-soluble coolants with anti-galling additives are preferred for titanium alloys—these lubricate and cool without leaving residue that could affect surface finish.

Fixturing, Rigidity, and Vibration Damping

Picture this: you’re machining a thin-walled aerospace bracket from 6al 4v titanium. Even the slightest vibration can ruin your tolerances or cause chatter marks. Rigid fixturing is essential—use the shortest possible tool overhang and robust, well-supported workholding. Damping pads or polymer inserts can help absorb vibrations, especially for long, slender parts.

When tolerances are ultra-tight or part geometry is complex, 5-axis machining centers shine. Their ability to approach the part from multiple angles minimizes repositioning, reduces tool deflection, and helps keep heat conductivity of titanium in check. If your in-house capabilities are limited, or you’re dealing with thin-walled, heat-sensitive, or intricate Ti-6Al-4V parts, consider outsourcing to a certified CNC partner with advanced 5-axis and high-pressure coolant systems. XTJ’s CNC machining services offer the kind of process control and certifications (ISO 9001:2015, IATF16949) that help mitigate risk and ensure repeatability for demanding titanium jobs.

Setup Checklist for Consistent Tolerances

- Tool nose radius and edge prep: Select honed or edge-prepped carbide tools with TiAlN or multilayer coatings designed for titanium.

- Conservative engagement and stepovers: Use low radial engagement and moderate feed rates to control heat and avoid work hardening.

- High-pressure through-tool coolant: Ensure coolant is delivered directly to the cutting zone to maximize chip evacuation and cooling.

- Trochoidal strategies for slotting: Use dynamic toolpaths to maintain consistent chip load and reduce localized heat buildup.

- Chipbreaker selection: Choose inserts with effective chipbreakers to prevent chip wrapping and tool damage.

- Minimum overhang: Keep tools as short and rigid as possible to limit deflection and vibration.

- Probing and in-process inspection: Use touch probes or laser measurement to monitor critical features and adjust for thermal growth.

- Deburr/polish steps for edges: Finish with gentle deburring and polishing to enhance surface quality and reduce galling risk.

Common Pitfalls vs. Corrective Actions in Ti-6Al-4V Machining

| Pitfall | Corrective Action |

|---|---|

| Built-up edge, rapid tool wear | Use coated carbide tools, high-pressure coolant, and correct feeds/speeds |

| Chatter, poor surface finish | Increase rigidity, minimize tool overhang, use vibration damping |

| Thermal growth, loss of tolerance | Monitor part temperature, use in-process probing, reduce cut depths |

| Stringy chips, chip wrapping | Employ chipbreakers, trochoidal milling, optimize coolant flow |

| Work hardening, tool breakage | Maintain consistent chip load, avoid tool dwell, use sharp inserts |

Mastering Ti-6Al-4V machining means controlling heat at every stage—understand the heat conductivity of titanium, optimize your setup, and let process discipline drive repeatable results.

In summary, successful machining of grade 5 titanium hinges on understanding its unique blend of low titanium heat conductivity, high strength, and work hardening. By choosing the right tools, optimizing coolant delivery, and maintaining rigid setups, you can achieve precision and surface quality that meets the strictest aerospace or medical standards. When in doubt, or when facing complex geometries and ultra-tight tolerances, leveraging a specialized CNC partner with advanced process controls can be the difference between success and frustration. Next, we’ll dive into welding best practices—so you can preserve those carefully engineered properties all the way through final assembly.

Welding Best Practices That Protect Ti-6Al-4V Properties

When you’re welding grade 5 titanium—also known as Ti-6Al-4V—you’re not just joining metal, you’re preserving the alloy’s exceptional strength, ductility, and corrosion resistance. Sounds complex? It doesn’t have to be, as long as you build your workflow around one core principle: absolute control over contamination and heat. Let’s break down the practical steps that ensure your welds maintain the high-performance ti-6al-4v properties engineers rely on.

Joint Design and Edge Preparation for Clean Fusion

Imagine prepping a titanium part and wondering, “Will this weld hold up?” The answer starts with cleanliness and careful joint design. Any contamination—be it from fingerprints, shop dust, or embedded particles—can embrittle the weld and ruin those prized titanium 6al 4v properties. Always use dedicated, clean tools and wear lint-free gloves. Avoid steel wool, shared grinding wheels, or anything that could introduce foreign metals. Before fit-up, wipe all joint surfaces and filler rods with an approved solvent like acetone or MEK, and let them air dry. Grind or file joint edges to remove oxides, but work slowly to minimize heat input. For thicker sections, follow qualified procedures for joint geometry (such as square butt or V-groove), and ensure tight fit-up to reduce heat and minimize exposure to air during welding.

Shielding Gas Purity and Trailing Shield Techniques

Ever seen a titanium weld turn blue or gray? That’s a warning sign—color changes signal contamination. The molten and cooling weld pool must be protected from air until it drops below critical temperatures (typically 500–800°F), where oxygen and nitrogen can no longer embrittle the alloy. Use high-purity argon for both torch shielding and back purging. Gas lenses and oversized cups help create a stable, laminar flow around the arc. For every pass, a trailing shield—either purchased or custom-made—should follow behind the torch, continuing the gas coverage over the weld and heat-affected zone until it has cooled below the discoloration threshold. Back purging is mandatory for full-penetration welds or tube/pipe: use commercial dams and monitor oxygen levels to ensure the purge is effective. Avoid rubber hoses for gas delivery, as they can introduce contaminants; opt for clean, non-porous plastics instead.

Managing Heat Input, Interpass Practices, and Distortion

Worried about losing ductility or causing distortion in your ti 6al 4v alloy? Excessive heat input is the culprit. Stick to qualified procedures for amperage and travel speed, and use chill blocks if possible to limit the size of the heat-affected zone (HAZ). For multi-pass welds, keep interpass temperatures low and avoid letting the part linger above critical temperatures. Allow the weld to cool under inert gas coverage before moving on. If you notice excessive warping, consider adjusting your sequence or fixturing to better control distortion. Remember, the low thermal conductivity of titanium means heat stays localized—good for controlling the weld, but bad if you let temperatures get away from you.

Inspection, NDT, and Post-Weld Finishing

How do you know your welds have preserved the original ti 6al 4v material properties? Inspection is your safety net. Start with visual checks: a bright, silvery weld bead is the goal; straw or light brown may be acceptable, but blue, gray, or white signals unacceptable contamination and requires rework [The Fabricator]. For critical parts, supplement visual checks with NDT methods like dye penetrant or radiography, as specified by AWS D1.9/D1.9M or other relevant codes. Portable hardness testing can provide additional assurance, but always compare results to the expected range for your specific alloy and weld procedure. For medical or aerospace applications, maintain full traceability of all weld records and qualification paperwork.

-

Welding Procedure Template for Ti-6Al-4V:

- Material identification and certification review

- Joint preparation: grind, deburr, solvent-clean all surfaces

- Fit-up and tack welds using dedicated, clean tools

- Shielding gas: verify purity and flow rate per code

- Torch cup and trailing shield selection for maximum coverage

- Purge setup: install dams, monitor oxygen levels, verify flow

- Interpass handling: maintain low temperatures, cool under inert gas

- Visual inspection: check weld color and bead quality

- NDT method selection: dye penetrant, radiography, or others as required

- Filler metal selection: Use only those specified in AWS A5.16/A5.16M or EN ISO 24034, matched to base metal when required by the procedure

For titanium, cleanliness and shielding are everything—protect the puddle until below discoloration risk.

Key Takeaways for Welding Titanium Ti-6Al-4V

- Absolute cleanliness and shielding are non-negotiable for maintaining titanium ti 6al 4v weld integrity.

- Use dedicated tools, wear gloves, and clean all surfaces—including filler rods—before welding.

- Maintain inert gas coverage with both torch and trailing shields, and always back purge for full-penetration welds.

- Control heat input to prevent embrittlement and distortion; let parts cool under gas coverage between passes.

- Inspect welds visually (color is a key indicator) and supplement with NDT as required by your application or code.

- Follow qualified procedures and document every step for traceability, especially in critical or regulated environments.

By following these best practices, you’ll preserve the engineered ti-6al-4v properties that make grade 5 titanium the alloy of choice for demanding applications. Ready to optimize the microstructure and further enhance performance? Up next: practical heat treatment routes for Ti-6Al-4V and how they influence the balance between strength and toughness.

Heat Treatment and Microstructure Made Practical

Ever wondered why two parts made from the same ti 6al-4v can perform so differently? The answer often lies in heat treatment and resulting microstructure. For engineers and fabricators, understanding how heat-treating routes affect 6al 4v properties is essential to unlocking the full performance potential of this widely used alloy.

Stress Relief Anneal and Microstructure Stabilization

When you machine or weld ti6al4v titanium alloy, residual stresses can build up—potentially leading to distortion or even cracking in service. A stress relief anneal, performed at a temperature well below the beta transus, helps stabilize the microstructure and reduce these stresses. This process maintains the balance between alpha and beta phases and preserves the fine equiaxed grain structure that supports both strength and ductility. Always refer to the governing specification (such as AMS 4965 or applicable ASTM/AMS standards) for precise temperature and hold time, as these can vary by product form and final application.

- Verify specification and product form (e.g., bar, plate, forging, or titanium alloy ti 6al 4v sheet)

- Clean and fixture parts to prevent contamination and distortion

- Ramp temperature in a controlled environment (inert atmosphere or vacuum as required)

- Soak at the specified setpoint for the required duration

- Cool per the specified route—furnace cool, air cool, or water quench depending on process

- Post-heat treatment verification: hardness checks and microstructure evaluation

- Note: Insert precise parameters only if sourced from AMS/ASTM or OEM specs

Microstructure control in Ti‑6Al‑4V drives the tradeoff between strength and toughness—document your HT route and verify with test coupons.

Solution Treatment, Aging, and Property Balancing

Looking for a boost in strength or fatigue resistance? Solution treatment and aging (STA) is the go-to process. Here, the alloy is heated just below its beta transus temperature (around 980°C for Ti-6Al-4V, per ASM properties), soaked, and then cooled at a controlled rate. This step dissolves some of the alpha phase, and the subsequent aging step encourages the precipitation of fine secondary alpha within the retained beta phase. The result: increased hardness and strength, especially when rapid cooling (like water quenching) is followed by proper aging. However, excessive hardness can reduce ductility and impact toughness, so process parameters must be carefully balanced.

Microstructure: Alpha, Beta, and Colony Size Effects

Imagine examining a polished cross-section of ti6al4v titanium alloy under the microscope. You’ll see a mixture of primary alpha grains, retained beta, and—depending on cooling rate—secondary alpha precipitates. Slow cooling (furnace cool) favors coarser, equiaxed alpha grains, which enhance ductility but lower strength. Fast cooling (water quench) leads to finer features and higher hardness, as seen in the increased Rockwell hardness after aging in water-quenched specimens. The choice of cooling rate and subsequent aging is your lever to tune 6al 4v properties for the desired balance of strength, toughness, and machinability.

Impact on Fatigue and Fracture Performance

Why does microstructure matter so much for fatigue and fracture? Finer alpha colonies and well-dispersed secondary alpha can block crack initiation and slow crack growth, improving fatigue life. Conversely, overly coarse grains or excessive retained beta can lower toughness and make the alloy more susceptible to fracture under impact or cyclic loading. That’s why critical aerospace and medical parts require not just the right chemistry, but also traceable heat-treatment records and microstructure verification—ensuring every load is processed to the correct asm properties standard.

Pairing heat treatment with machining allowances is also smart: even minor distortion can throw off tight tolerances, so always plan for post-HT inspection and adjustment. For safety-critical applications, track serial-numbered loads, maintain full traceability, and document every step from furnace cycle to final hardness test. This approach not only meets regulatory requirements but also ensures your titanium alloy ti 6al 4v parts deliver consistent, reliable performance in service.

In summary, mastering heat treatment for Ti-6Al-4V is about understanding how temperature, time, and cooling rate shape microstructure—and, in turn, mechanical behavior. Whether you’re targeting maximum strength, improved fatigue life, or just stress relief after welding, always consult the latest asm properties and relevant specifications to guide your process. Up next: we’ll explore how additive manufacturing and powder routes can further tailor Ti-6Al-4V properties for advanced applications.

Additive Manufacturing and Powder Routes That Work

When you see complex aerospace brackets or custom medical implants made from grade 5 titanium, there’s a good chance they came from an additive manufacturing (AM) process. But what really goes into making high-quality parts from titanium powder? Let’s break down how powder characteristics, build parameters, and post-processing all work together to deliver the ti-6al-4v material properties engineers expect.

Powder Specifications and Quality Control

Imagine you’re preparing to print a critical Ti-6Al-4V component. The first step is selecting the right powder. Not all titanium powders are created equal—attributes like particle size, shape, and chemistry directly affect printability and final part quality. For example, powders produced by electrode inert gas atomization, such as Osprey TI-6Al-4V, are engineered for high sphericity and minimal internal porosity, supporting consistent layer spreading and melting.

| Attribute | What to Verify | Design/Process Impact |

|---|---|---|

| Particle Size Distribution | Range (e.g., 20–63 μm for L-PBF); D10, D50, D90 | Layer thickness, flowability, density of ti6al4v parts |

| Morphology | Spherical shape, low satellites | Uniform spreading, reduced defects |

| Oxygen/Nitrogen Limits | Per ASTM F2924/F3001, e.g., O <0.20%, N <0.05% | Mechanical properties, ductility |

| Flowability | Measured by Hall flow or similar test | Consistent recoating, layer quality |

| Reuse Criteria | Limits on number of cycles, oxygen pickup | Long-term part consistency |

Common AM Build Defects and Mitigation

Sounds complex? Here’s what really matters: controlling porosity and fusion quality during the build. In laser powder bed fusion (LPBF), the main risks are lack of fusion (LOF) defects—caused by insufficient energy density—and gas pores or keyholing from excessive energy input (AIP Advances).

- Low energy density: Leads to incomplete melting, irregularly shaped pores, and lower ti64 density.

- High energy density: Causes keyholing and spherical gas pores that can compromise fatigue life.

- Optimal window: For Ti-6Al-4V, a volumetric energy density of 51–67 J/mm³ can achieve relative densities above 99.95%.

Besides internal porosity, external defects like unmelted powder, balling, and cracks can appear if parameters aren’t tightly controlled. Consistent argon shielding and precise scan strategies help mitigate these risks. Always monitor oxygen content in the build chamber to prevent unwanted embrittlement and ensure target ti-6al-4v material properties are achieved.

Post-Processing: HIP, Heat Treatment, and Machining

Ever wondered how printed parts match the performance of wrought alloys? It’s all about post-processing. Hot isostatic pressing (HIP) collapses residual pores, increases density of ti6al4v, and transforms the as-built martensitic microstructure into a more ductile alpha + beta phase. This step is especially crucial for fatigue-critical or biomedical components (PMC).

- Stress relief or HIP per spec (e.g., 930°C/100 MPa/4h for SLM builds)

- Surface finishing (sandblasting, polishing, or chemical etching)

- Support removal and dimensional restoration

- Non-destructive testing (NDT) for internal defects

- Mechanical testing on witness coupons for tensile, fatigue, and hardness

HIP not only improves mechanical strength and ductility but also helps achieve the required density of titanium 6al-4v in AM parts, matching or exceeding industry standards. Surface treatments like chemical etching can further enhance fatigue life and biocompatibility, especially for medical implants.

Property Verification and Certification

How do you know your AM part meets spec? Property verification is your safety net. Always link final mechanical test results—including tensile strength, elongation, and hardness—to the specific powder batch and build record. For aerospace or medical, traceability is non-negotiable: keep a clear chain from powder certs through to final property testing.

- Review powder certificates for chemistry and lot traceability

- Document all build parameters and environmental controls

- Correlate mechanical test results to both build and post-processing records

- Maintain full traceability for regulatory or customer audits

When done right, additive manufacturing can deliver titanium ti6al4v parts with density ti64, microstructure, and mechanical performance rivaling or surpassing conventionally processed material. By focusing on powder quality, process control, and robust post-processing, you ensure the final part lives up to the promise of advanced ti-6al-4v material properties—ready for the most demanding applications.

Next, we’ll guide you through practical procurement strategies—so you can secure the right titanium grade, product form, and certifications for every project.

Procurement Guidance and Smart Next Steps for Grade 5 Titanium Projects

Common Product Forms and Specifications

When you’re ready to source grade 5 titanium for your project, you’ll notice there’s no one-size-fits-all format. Imagine you’re building an aerospace bracket, a medical implant, or a custom racing part—each calls for a different product form and, often, a different specification. So, what are your options?

- Bar – Ideal for precision machining and load-bearing components; check AMS 4928 for bars and forgings.

- Plate – Used in structural and high-strength applications; commonly supplied to AMS 4911 or ASTM B265 standards.

- Sheet – Preferred for lightweight panels and formed parts; look for AMS 4911 or ASTM specs for quality assurance.

- Forgings – Chosen for critical, high-integrity parts where directional strength is key.

- Tube – Used in piping, frames, and heat exchangers, often supplied to aerospace or industrial standards.

- AM Powder – For additive manufacturing, where powder quality and certification directly impact final part performance.

Always verify that your titanium grade matches the required specification for your industry. For example, ams4911 is the go-to spec for aerospace-grade titanium sheet and plate, ensuring consistency in chemistry and mechanical properties across suppliers.

Lead Time, Availability, and Certification Needs

Ever found yourself waiting weeks for material to arrive, only to learn it doesn’t meet your cert requirements? Lead time on titanium alloy 6al 4v can vary widely depending on form, size, and certification level. Stock distributors typically offer the fastest turnaround on standard sizes, while custom mill runs may take longer but allow for tailored dimensions or special testing.

- Certifications: For aerospace, medical, or defense projects, always request full material test reports (MTRs) and traceability to the melting batch. Common certs include AMS, ASTM, and ISO standards.

- Availability: Sheets and bars in popular sizes are often in stock, but specialty forgings or AM powder may require custom order and longer lead times.

- Planning tip: Communicate your certification and inspection needs early—especially for projects where titanium grade compliance is critical.

Cost Drivers and Lifecycle Planning

Wondering what influences the grade 5 titanium price or the titanium sheets price you see in quotes? The price on titanium is shaped by several factors:

- Raw material cost: Titanium is energy-intensive to refine and alloy, making it more expensive than steel or aluminum.

- Product form: Sheets and plates processed to tight tolerances or special surface finishes generally command higher prices.

- Certifications: Aerospace or medical-grade certifications add to cost due to additional testing and traceability.

- Order size: Small or custom orders often have a higher per-unit cost than bulk mill runs.

- Value-added processing: CNC machining, surface finishing, and heat treatment all contribute to final part cost.

Lifecycle planning is just as important. Titanium alloy 6al 4v delivers long-term value through corrosion resistance and durability, often offsetting its higher upfront price with reduced maintenance and longer service life in demanding environments.

When to Partner with a Precision CNC Shop

Imagine you’re facing a tight deadline, ultra-thin walls, or a geometry that stretches your in-house capabilities. That’s when partnering with a certified CNC machining provider can make all the difference. Expert shops offer:

- Material readiness: Immediate access to certified ti gr 5 stock in bar, plate, or sheet form.

- Rapid DFM feedback: Design-for-manufacturing insights to optimize your part for both performance and cost.

- Tight-tolerance machining: Advanced 4- and 5-axis centers capable of holding tolerances down to +/- 0.005mm—essential for aerospace grade titanium and medical work.

- Process control: ISO 9001:2015 and IATF16949 certifications to ensure quality and traceability.

- Schedule risk mitigation: Accelerated lead times and expert fixturing to reduce rework and protect titanium’s engineered properties.

When your project’s risk or complexity exceeds what you can handle internally, it’s smart to consult a trusted CNC partner. XTJ’s CNC machining services offer rapid turnaround, robust process controls, and deep expertise in titanium—all key for projects where every detail matters.

| Provider Type | Minimum Order Size | Certifications | Lead Time | Value-Added Processing |

|---|---|---|---|---|

| XTJ CNC Service Provider | customized (prototype or production) | ISO 9001:2015, IATF16949, AMS/ASTM certs | As fast as 3 days | Machining, finishing, rapid DFM, inspection |

| Stock Distributor | Standard bar, plate, sheet sizes | Mill certs (AMS/ASTM), basic ISO | 1–2 days (in stock) to 2–4 weeks (special) | Cutting, basic surface prep |

| Mill Source | Large batch/custom order | Full traceability, custom testing | 4–12 weeks (custom run) | Hot/cold working, custom dimensions |

Note: Always confirm your titanium grade and certification needs at the RFQ stage, especially for regulated industries.

In summary, smart procurement of grade 5 titanium means matching your product form, certification, and schedule needs to the right sourcing channel. For complex, high-risk, or time-sensitive projects, partnering with a certified CNC shop like XTJ can streamline the process and protect your investment. Ready to move forward? Reach out for technical support, a quote, or to discuss the best approach for your next titanium alloy 6al 4v challenge.

Grade 5 Titanium: Frequently Asked Questions

1. Is grade 5 titanium good for demanding applications?

Grade 5 titanium, also known as Ti-6Al-4V, is highly valued for its exceptional strength-to-weight ratio and corrosion resistance. This makes it a top choice for aerospace, medical implants, and energy components where reliability and performance are critical. Its ability to maintain mechanical properties under stress and in harsh environments sets it apart from many other materials.

2. Why is grade 5 titanium more expensive than other grades?

Grade 5 titanium is more costly due to its advanced alloying process, which combines titanium with aluminum and vanadium for enhanced strength and processability. The production involves vacuum melting and precise control, leading to higher manufacturing costs. Additionally, certifications for aerospace or medical use, and the material's demand in critical sectors, contribute to its premium price.

3. How does grade 5 titanium compare to grade 2 titanium?

Grade 5 titanium offers much higher strength and is heat treatable, making it ideal for high-stress and weight-sensitive applications. In contrast, grade 2 titanium is commercially pure, easier to form and weld, and is preferred for applications where ductility and corrosion resistance are more important than strength, such as chemical processing and marine environments.

4. What are the main uses of grade 5 titanium?

Grade 5 titanium is widely used in aerospace structures, medical implants, high-performance automotive parts, energy sector hardware, and advanced consumer products. Its combination of strength, low density, and corrosion resistance makes it suitable for both structural components and precision parts in industries demanding top performance.

5. When should I use a certified CNC machining service for grade 5 titanium parts?

Certified CNC machining services are recommended when your project requires ultra-tight tolerances, complex geometries, or rapid turnaround. Professional shops, like XTJ, provide advanced 4- and 5-axis machining, high-pressure coolant systems, and quality certifications (ISO 9001:2015, IATF16949), ensuring your titanium parts meet strict standards while minimizing risk and lead time.

-

Posted in

aerospace materials, grade 5 titanium, ti-6al-4v, titanium grades comparison, titanium machining