Titanium Melting Point: 9 Essential Points You Can Use Now

Core facts about the titanium melting point

Ever wondered why titanium is prized in aerospace, medical, and advanced manufacturing? The answer often starts with its impressive melting point—a property that sets it apart from the melting point of common metals like aluminum or steel. But what exactly does "melting point" mean in metallurgy, and why does it matter so much for titanium?

Exact titanium melting point and unit conversions

Pure titanium melts at 1668 °C (3034 °F, 1941 K).

- 1668 °C = 3034 °F = 1941 K

- Melting point: Temperature where solid and liquid phases coexist in equilibrium.

- Boiling point: Temperature where liquid becomes gas (for titanium: 3287 °C, see next section).

- Softening temperature: Where the metal becomes pliable, but not yet liquid.

For engineers and designers, knowing the precise titanium melting point is crucial when selecting processes like casting, welding, forging, or machining. If you’re working with pure titanium, you’ll want to plan your thermal cycles and tooling around this number to avoid unwanted phase changes or material degradation.

Why melting range matters more for alloys

Sounds complex? It gets even more interesting with titanium alloys. Unlike pure metals, alloys don’t melt at a single temperature. Instead, they have a melting range—defined by the solidus (where melting starts) and liquidus (where melting is complete) temperatures. This range is especially important for processes like welding and casting, where partial melting can impact strength and microstructure.

For example, common alloys like Ti-6Al-4V (also known as Grade 5 titanium) will start to melt at a slightly lower temperature than pure titanium and finish melting at a slightly higher one, depending on the exact composition. This behavior is typical for many engineering alloys and is covered in more detail in later sections, along with the concepts of solidus and liquidus.

Melting point versus boiling point and softening

It’s easy to mix up melting point, boiling point, and softening temperature. Here’s a quick way to keep them straight:

- Melting point of titanium: Solid becomes liquid at 1668 °C.

- What is the boiling point of titanium? It’s much higher: 3287 °C (boiling is rarely reached in standard processing).

- Softening temperature: Below the melting point, where titanium can be forged or shaped but remains solid.

Understanding these differences helps you avoid costly processing errors. For instance, if you heat titanium above its melting point but below its boiling point, you’ll get a liquid metal suitable for casting—but go too far, and you risk vaporization or contamination.

Preview: Why these numbers matter for real-world processes

Why care about these details? The titanium metal melting point shapes how you approach every heat-based process. Whether you’re casting a medical implant, welding an aerospace bracket, or forging a custom part, the precise temperature window determines quality and performance. In later sections, you’ll see how alloying elements create melting ranges, and how phase changes—like the alpha–beta transformation—impact processing windows and final properties.

If you’re comparing the titanium melting point to the melting point of common metals, you’ll notice titanium’s value is significantly higher than aluminum (660 °C) or iron (1538 °C), making it ideal for high-temperature and demanding environments.

In summary, knowing what is the melting point of titanium is your starting point for material selection and process planning. The next sections will build on this foundation, exploring how alloys, phase diagrams, and processing methods all tie back to these critical temperatures.

Phase diagram essentials and processing insights

When it comes to understanding why the melting point of titanium matters in real-world manufacturing, the phase diagram is your roadmap. But what is a phase diagram, and how does it guide forging, heat treatment, and casting of titanium? Let’s break it down for you.

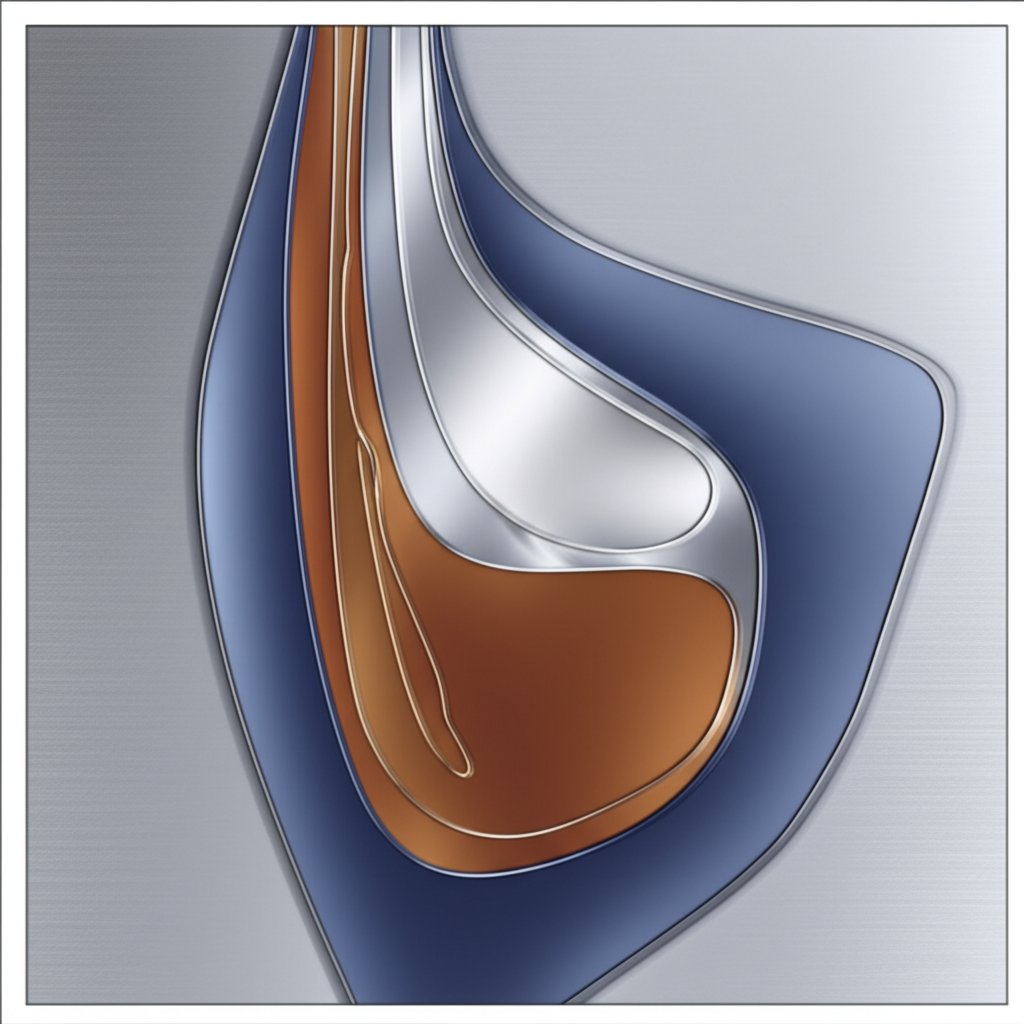

Annotated titanium phase diagram overview

Imagine a graph where the vertical axis is temperature (from room temperature up to above the melting temperature titanium), and the horizontal axis is composition (from pure titanium on the left to increasing alloying elements on the right). This phase diagram divides into four main regions:

- Alpha (α) region: Low temperatures, pure titanium or with alpha-stabilizers. Titanium structure here is hexagonal close-packed (hcp).

- Beta (β) region: High temperatures, or with beta-stabilizing elements. Structure is body-centered cubic (bcc).

- Alpha + Beta (α+β) region: Intermediate temperatures or compositions—both phases coexist.

- Liquid region: Above the melt point of titanium (the liquidus line), where the metal is fully molten.

Between the solid (alpha, beta, or alpha+beta) regions and the liquid region, you’ll notice two important boundaries: the solidus line (where melting starts) and the liquidus line (where melting completes). The beta-transus line (Tβ) is a key temperature at which titanium transforms from alpha to beta structure—this is crucial for heat treatment and forging decisions.

Text-based diagram description: Picture a vertical temperature axis (bottom to top) and a horizontal composition axis (left: pure Ti, right: increasing alloying). Regions are labeled: bottom left is α, top left is β, center band is α+β, and the topmost area is liquid. Solidus and liquidus lines slope upward with added alloying, and the beta-transus is a nearly horizontal line separating α or α+β from β. ASM Handbook: Ti (Titanium) Binary Alloy Phase Diagrams

Alpha, beta, and alpha+beta regions in practice

Why do these regions matter for processing? Each phase or phase mixture brings different mechanical and thermal properties. For example, the alpha phase is stable up to about 882 °C (as seen in pure titanium), giving it good weldability and oxidation resistance. The beta phase appears at higher temperatures or with beta-stabilizing elements, offering improved formability and strength after heat treatment. Most titanium alloys, like Ti-6Al-4V, spend significant time in the alpha+beta region during processing, which allows for tailored microstructures.

Alloying elements shift these boundaries. Add aluminum or oxygen, and you stabilize the alpha phase, raising the beta-transus temperature. Add vanadium, molybdenum, or chromium, and you stabilize the beta phase, lowering the beta-transus. This means the melting point of ti and the range between solidus and liquidus can move depending on composition—a critical consideration for controlling the titanium freezing point and melt behavior during casting or welding.

Phase boundaries and processing windows

How does this help you on the shop floor or in the design office? The phase diagram tells you when to heat, forge, or cool to achieve the desired titanium structure and properties. Here’s a quick guide:

- Forging: Often done just below or in the alpha+beta region for balanced strength and ductility.

- Heat treatment: Solution treatment above the beta-transus, then rapid cooling (quenching) to lock in beta-derived structures, followed by aging to precipitate fine alpha for strength.

- Casting/welding: Melting must reach above the liquidus, but controlling the melt and solidification path ensures a desirable microstructure and avoids defects.

In summary, the phase diagram is more than an academic chart—it’s a practical tool for managing the melting point titanium and phase evolution, helping you avoid defects, optimize strength, and tailor properties for demanding applications. As you continue, you’ll see how these boundaries translate into solidus and liquidus temperatures for specific alloys, and why understanding the titanium freezing point is essential for quality control and process success.

Alloy solidus and liquidus temperatures you can use

When you’re planning to cast, weld, or forge titanium components, knowing the exact temperature windows for each alloy is critical. Unlike pure titanium, which melts at a single point, titanium alloys such as grade 2 titanium and ti-6al-4v (also known as grade 5 titanium) have distinct solidus and liquidus temperatures. This melting range is where the material transitions from solid to fully liquid, and it’s a key factor for process control, defect avoidance, and achieving desired properties.

Solidus and liquidus for Grade 2 and Grade 5

Let’s break down the numbers. Commercially pure (CP) grade 2 titanium is widely used for its corrosion resistance and moderate strength, while ti-6al-4v (grade 5) is the go-to for high-performance structural applications. Each has a slightly different melting behavior due to composition:

| Alloy Name | Nominal Composition | Solidus (°C/°F) | Liquidus (°C/°F) | Primary Source | Notes |

|---|---|---|---|---|---|

| Grade 2 Titanium (CP) | Unalloyed Ti | 1665 / 3030 | 1665 / 3030 | ASM MatWeb | Very narrow melting range, often treated as a single point in practice; high corrosion resistance; easy to weld |

| Ti-6Al-4V (Grade 5) | Ti-6%Al-4%V | 1604 / 2920 | 1660 / 3020 | ASM MatWeb | Melting range; high strength; referenced in AMS 4928, AMS 4911 |

Notice how ti-6al-4v (also called 6al 4v or Grade 5) starts melting at a lower temperature than pure titanium, but is fully liquid at a slightly lower temperature as well. This melting range is typical for most engineering alloys, and it’s especially important for applications where precise control of the melt is required—think aerospace welding or medical device casting.

How alloying shifts melting behavior

So, what’s behind these differences? It’s all about the alloying elements. Adding aluminum (Al) and vanadium (V) to titanium creates the alpha-beta structure that gives grade 5 titanium its unique blend of strength and processability. But these elements also lower the solidus temperature compared to pure titanium, creating a melting range rather than a single point. This means you need to carefully monitor your furnace or weld pool to avoid partial melting or hot cracking.

- Aluminum stabilizes the alpha phase, increasing strength and corrosion resistance.

- Vanadium stabilizes the beta phase, improving ductility and workability at high temperatures.

- The result: a melting range (solidus to liquidus) that is slightly lower and broader than pure titanium.

For reference, the solidus for ti 6al 4v is about 1604 °C (2920 °F), with the liquidus at 1660 °C (3020 °F), as confirmed by ASM MatWeb. These values are also referenced in key aerospace specifications such as AMS 4928 (for bar and forging) and ams4911 (for sheet and plate).

Implications for casting, welding, and forging

Imagine you’re casting a titanium part. If your temperature control isn’t precise, you might only partially melt the alloy, leading to defects or inhomogeneous structure. In welding, straying into the melting range can cause microsegregation or hot cracking, especially with alloys like 6al 4v. For forging, working within the alpha+beta region below the solidus is preferred to maintain ductility and avoid unwanted melting.

- Casting: Requires exceeding the liquidus for full melt, but beware of segregation in the melting range.

- Welding: Control is key; melting range influences pool shape, cooling, and the risk of defects.

- Forging: Typically done below solidus, often near the beta-transus, to balance formability and strength.

For engineers, these numbers aren’t just trivia—they’re the foundation for selecting the right process window, setting up thermal cycles, and predicting how the alloy will behave under heat. Always check the relevant material specification—like AMS 4928 or ams4911—for precise values and allowable process windows for your specific alloy and product form.

As you move forward, keep in mind how even small changes in alloy chemistry can shift these critical temperatures, affecting everything from microstructure to mechanical performance. Next, we’ll explore how impurities and interstitials—like oxygen and nitrogen—can further reshape melting behavior and influence your process outcomes.

Impurities and interstitials that reshape melting behavior

Ever wondered why two titanium parts—made from the same alloy—can perform so differently after melting or welding? It often comes down to the tiniest ingredients: interstitials and trace impurities. Even in small amounts, elements like oxygen, nitrogen, hydrogen, and carbon can dramatically change how titanium melts, solidifies, and ultimately performs. Let’s break down how these atomic-scale additions influence melting titanium and what you need to watch for in real-world processing.

Interstitials and their impact on titanium melts

When you ask, “What temperature does titanium melt?” the answer isn’t always as simple as a single number. That’s because interstitial elements—atoms small enough to squeeze between the titanium atoms in the crystal lattice—can subtly shift the melting point and, more importantly, alter the way titanium behaves in the molten and solidified states. Here’s how each major interstitial affects titanium alloys:

- Oxygen (O): Increases strength and hardness, but also embrittles the material. High oxygen content raises the risk of cracking during solidification and welding. Oxygen has a strong affinity for titanium and can significantly influence the microstructure, especially in the heat-affected zone of welds (ResearchGate: The effect of impurities elements on titanium alloy Ti-6Al-4V).

- Nitrogen (N): Similar to oxygen, nitrogen hardens and embrittles titanium. It can also slightly lower ductility, making the alloy more susceptible to cracking under stress or rapid cooling.

- Hydrogen (H): The most notorious impurity for titanium. Hydrogen can be absorbed during melting, welding, or even service, and tends to precipitate as brittle titanium hydride phases upon cooling. This leads to hydrogen embrittlement, which can cause catastrophic failure, especially in welded joints.

- Carbon (C): Carbon increases strength but can promote carbide formation at grain boundaries, which may reduce ductility and toughness. Excess carbon is particularly problematic in powder metallurgy and sintering processes.

Key reminder: Always verify interstitial content with a thorough titanium analysis before melting or welding. Exceeding specification limits—even slightly—can compromise mechanical properties and lead to costly failures.

From melt to microstructure: How impurities shape solidification

Imagine pouring a titanium melt into a mold or creating a weld pool. The way that pool cools and solidifies is shaped not just by temperature, but by the presence of these interstitials and impurities. Here’s what happens:

- Viscosity of the melt: High levels of oxygen and nitrogen can increase melt viscosity, making the liquid titanium more sluggish and harder to cast or weld smoothly.

- Grain structure: Interstitials can pin grain boundaries, leading to finer or more brittle microstructures. For example, increased oxygen content can refine grains but also promote the formation of brittle alpha-case layers, especially near surfaces exposed to air during high-temperature processing.

- Solidification defects: Hydrogen, if absorbed during the melt, can precipitate as hydrides during cooling. These brittle phases may not be visible to the naked eye but can cause cracking or sudden failure under load. This is especially critical in welded joints or castings for demanding applications.

In practice, even if the bulk melting point shifts only slightly, the presence of these elements can have outsized effects on weld pool stability, feedability during casting, and the toughness of the final part. That’s why a detailed titanium analysis is essential before and after any high-temperature process.

Contamination sources and how to avoid them

So, where do these interstitials come from? And how can you minimize their impact when melting or welding titanium?

- Atmospheric exposure: Titanium is highly reactive at elevated temperatures. Even brief contact with air (oxygen and nitrogen) or moisture (hydrogen) can introduce impurities.

- Processing environment: Melting, casting, and welding should be done in vacuum or under high-purity inert gas (like argon) to prevent contamination.

- Tooling and crucibles: Use clean, non-reactive materials for crucibles and weld backing to avoid introducing carbon or other contaminants.

- Powder metallurgy and binders: In additive or injection-molded parts, binder decomposition can introduce carbon or hydrogen if not properly removed before sintering.

Sounds complex? The good news is that most modern melting and welding setups include rigorous controls—vacuum chambers, inert gas purges, and strict cleanliness protocols—to keep these impurities at bay. But the risk never goes away completely, so regular titanium analysis is your best insurance against unexpected failures.

In summary, while the question “at what temperature does titanium melt?” is foundational, the real-world answer is shaped by the invisible hand of interstitials and impurities. Tiny shifts in chemistry can lead to big changes in performance, weldability, and reliability. Next, we’ll explore how industrial melting methods help control these variables and ensure high-quality titanium parts every time.

Industrial melting and remelting methods explained

When you ask, "Can titanium be melted?" or "Does titanium melt cleanly enough for aerospace or medical parts?"—the real answer depends on the industrial melting method you choose. Each process is uniquely designed to handle the challenges posed by titanium’s high melting point, reactivity, and the need for ultra-clean, inclusion-free metal. Let’s break down the major industrial routes and see how they stack up for quality, cost, and application.

How VAR, EBM, VIM, and skull methods work

Imagine you’re tasked with producing a titanium ingot for jet engines or biomedical implants. You need to ask: What melting method ensures the right purity and microstructure for your application? Here are the primary industrial methods:

- Vacuum Arc Remelting (VAR): Uses a consumable titanium electrode melted by an electric arc under vacuum. The molten metal drips into a water-cooled copper crucible, solidifying into an ingot. This is the standard for most titanium alloys and is especially valued for its ability to remove gas impurities and produce uniform structure.

- Electron Beam Cold Hearth Melting (EBM/EBCHR): Utilizes a focused electron beam to melt titanium scrap, sponge, or alloy feedstock in a water-cooled copper hearth. The “cold hearth” allows heavy and light inclusions to separate before solidification, resulting in extremely clean ingots (FIKO Electron Beam Study).

- Vacuum Induction Melting (VIM): Employs induction coils to melt titanium in a water-cooled crucible, often copper, under vacuum or inert gas. This method is favored for small-batch, specialty alloys where precise composition control is essential.

- Cold Crucible Induction Melting (CCIM): A variant of VIM, using segmented, water-cooled copper crucibles to avoid contamination. Magnetic fields stir the melt for uniformity and prevent contact with refractory materials. Ideal for high-purity, specialty titanium products.

Contamination control and cleanliness tiers

Why do these melting methods matter so much for titanium? Because titanium’s high reactivity means it easily picks up oxygen, nitrogen, and other impurities at high temperatures—especially near its melting point ti. Each melting process offers different levels of control over contamination and inclusions:

| Process | Atmosphere/Pressure | Crucible/Contact Material | Cleanliness | Pros | Cons | Common Applications |

|---|---|---|---|---|---|---|

| VAR | High vacuum | Water-cooled copper | High (removes gas impurities) | Uniform ingots; mature tech; scalable | Complex electrode prep; risk of inclusions if feed is impure | Alloy ingots, aerospace, medical, general Ti products |

| EBM/EBCHR | Ultra-high vacuum | Water-cooled copper hearth | Very high (removes HDI/LDI inclusions) | Can use scrap; removes both heavy and light inclusions; direct melt of sponge | High equipment and operation cost; slower; lower throughput | High-purity ingots, recycling, aerospace critical parts |

| VIM | Vacuum/inert gas | Water-cooled copper | Moderate–high (good for clean feed) | Precise composition; small batch; flexible | Limited scale; less effective at impurity removal | Specialty alloys, R&D, medical |

| CCIM | Vacuum/inert gas | Segmented copper (no refractory) | Very high (minimizes crucible contamination) | Uniform melt; avoids refractory contact; low contamination | Still developing at industrial scale; costly | Ultra-pure, small-lot, high-spec titanium |

Each process is chosen based on the required cleanliness, alloy, and final application. For example, EBM is often selected when you need to minimize inclusions for critical aerospace components, while VAR is the workhorse for most alloy ingots due to its balance of quality and scalability.

Choosing a process for your alloy and application

So, can titanium melt by any of these methods? Yes—but the best method depends on your goals. Here are some practical scenarios:

- Mass production of standard alloys: VAR is typically the first choice for its reliability and cost-effectiveness. It’s especially effective for alloys where the melting point for titanium is tightly controlled and gas impurities must be minimized.

- High-purity or recycled feedstock: EBM/EBCHR shines for cleaning up scrap, sponge, or contaminated feed, thanks to its ability to remove both high-density and low-density inclusions.

- Specialty or small-batch alloys: VIM and CCIM are ideal for research, prototyping, or medical parts where tight composition and minimal contamination are critical.

But what about cost and scalability? EBM and CCIM offer the highest purity but at higher capital and operational costs. VAR represents a middle ground, balancing quality and throughput. VIM is best for small lots, where the question isn’t just "can titanium melt?" but "can it be melted precisely for my unique alloy?"

In summary, the route you choose for melting titanium isn’t just about reaching the melting point ti—it’s about matching the process to your alloy, application, and quality requirements. As you move into the next section, you’ll see how atmosphere and crucible choices further guard against contamination, ensuring your titanium parts meet the highest standards.

Atmosphere, crucibles, and contamination control

Ever wondered why titanium processing demands such strict environmental controls? The answer lies in its high reactivity at elevated temperatures, especially close to its melting and boiling points. If you’re planning to cast, weld, or melt titanium, understanding how atmosphere and crucible choices impact quality is essential—not just for achieving the right titanium heat resistance, but for ensuring your finished parts are free from costly defects and contamination.

Vacuum and inert gas considerations

When you heat titanium toward its melting point (1668 °C) and especially as you approach what is titaniums boiling point (3287 °C), the metal becomes intensely reactive. At these temperatures, titanium will eagerly absorb oxygen, nitrogen, and even hydrogen from its environment. This can result in embrittlement, loss of ductility, and surface contamination—problems that are nearly impossible to fix after the fact.

- Vacuum environments are preferred for melting and welding, as they minimize the presence of reactive gases.

- High-purity inert gases (like argon or helium) are used when vacuum is impractical, especially during welding or small-batch melting.

- Even trace amounts of air or moisture can lead to significant contamination, so process chambers are carefully sealed and purged.

- Pressure control is critical: Too low, and you risk vaporization or splattering; too high, and gas absorption may increase.

Why such fuss? Because as you approach the boiling point of titanium, the risk of vaporization, splatter, and rapid gas absorption spikes. That’s why melting and welding are rarely done above the melting point, and never near the boiling point in practical settings.

Crucible materials and contact reactions

Now, imagine pouring molten titanium into a container. What happens next depends on your choice of crucible. Titanium’s high temperature and chemical activity mean it will react with almost any conventional material—leading to contamination, inclusions, and even premature crucible failure.

| Crucible Material | Pros | Cons | Compatibility Notes |

|---|---|---|---|

| Water-cooled copper (skull/cold crucible) | Virtually no contamination; excellent thermal shock resistance | High energy cost; limited batch size; complex setup | Preferred for high-purity melts and critical parts |

| Graphite | Good thermal shock resistance; low cost | Severe carbon contamination; not suitable for most Ti alloys | Used for some NiTi alloys, but not for structural Ti |

| Ceramic oxides (e.g., Y2O3, CaO, BaZrO3) | Low oxygen contamination; good chemical stability | Poor thermal shock resistance; expensive; can crack | Best for small batches or as coatings on cheaper crucibles |

| AlN (Aluminum nitride) | Excellent chemical inertness and shock resistance | High cost; fabrication challenges | Promising for future scale-up |

Water-cooled copper skull crucibles are a game-changer—they keep the molten titanium suspended in a “skull” of solid titanium, preventing direct contact with the container. This method is ideal for maintaining purity and avoiding unwanted reactions, especially when high titanium heat resistance is required. Ceramic coatings (like Y2O3) can also help, but their poor shock resistance limits repeated use (ScienceDirect).

Managing evaporation and contamination

As you approach what is the melting and boiling point of titanium, evaporation and splatter become real risks. Titanium doesn’t burn easily in bulk, but at high temperatures, especially in the presence of oxygen, it can ignite or form brittle oxide layers—compromising both safety and material properties. That’s why controlling both the temperature and the atmosphere is essential.

- Keep processing temperatures just above the melting point—not near the boiling point titanium—to avoid vaporization.

- Always use a vacuum or high-purity inert gas shield to prevent oxidation, nitriding, or hydride formation.

- Choose crucible/contact materials based on your purity needs, batch size, and cost constraints.

- Monitor for signs of contamination—discoloration, inclusions, or unexpected brittleness—and adjust processes as needed.

Key takeaway: The combination of vacuum/inert gas control and carefully selected crucible materials is your best defense against contamination and property loss when melting or welding titanium.

In summary, the unique challenges of titanium melting—its high reactivity, elevated melting and boiling points, and demand for ultra-clean processing—mean that every detail of your environment and tooling matters. By mastering atmosphere management and crucible selection, you’ll ensure your titanium parts achieve their full potential, whether you’re building aerospace components or medical implants. Next, we’ll look at how melting points are measured and reported, so you can verify your process is truly under control.

How melting points are measured and reported

When you’re working with high-performance metals like titanium, knowing what is the melting temperature of titanium isn’t enough—you also need confidence in how those numbers are determined. So, how do labs and industry experts actually measure the temperature titanium melts at, and how can you trust the results for critical applications?

DSC/DTA for solidus and liquidus detection

Ever wondered how scientists pinpoint the start and finish of melting in titanium alloys? The answer lies in thermal analysis techniques like Differential Scanning Calorimetry (DSC) and Differential Thermal Analysis (DTA). These methods heat a small sample alongside a reference under controlled conditions, tracking heat flow or temperature differences as the material transforms from solid to liquid. The solidus (where melting starts) and liquidus (where melting completes) show up as distinct endothermic peaks or deviations in the output curve.

- Calibration: Instruments are calibrated using pure metals with certified melting points—often NIST-traceable standards—to ensure accuracy.

- Sample prep: Mass, shape, and placement in the crucible all affect results. Consistency is key for reproducibility.

- Atmosphere: High-purity inert gas or vacuum is used to prevent oxidation or contamination during heating.

- Data analysis: The onset of deviation from baseline marks the solidus; the end of the peak or return to baseline marks the liquidus. Reporting both values is best practice for alloys.

For ti melting temperature measurements, the first detectable deviation from baseline is often preferred over extrapolation methods for greater accuracy, especially with alloys that don’t show sharp melting transitions (NIST SP 960-15).

High-temperature pyrometry and emissivity

But what about situations where you need to measure the what temperature does titanium melt at during real-world processing—like welding, additive manufacturing, or casting—where contact methods won’t work? Enter optical pyrometry. This non-contact technique uses the infrared or visible light emitted by hot metal to estimate temperature. However, the accuracy depends heavily on knowing the material’s emissivity—a property that can change with surface finish, oxidation, and even temperature itself.

- Emissivity correction: Before trusting a pyrometer reading, calibrate with a reference (like a type S thermocouple) or use a known-emissivity paint—though these can degrade at high temperatures.

- Spot size and focus: Ensure the pyrometer is aimed precisely at the melt pool or hottest region for representative readings.

- Surface effects: Be aware that surface oxidation or contamination can alter emissivity and introduce error. Reporting estimated uncertainty is best practice.

Recent studies show that with careful calibration, radiation pyrometers can measure titanium temperatures up to 1550 K with less than 2.5% uncertainty—sufficient for most industrial needs.

Levitation techniques to avoid contamination

Imagine you need to measure the true melting point of titanium without any risk of crucible contamination. That’s where levitation calorimetry comes in. By using electromagnetic or aerodynamic forces to suspend a tiny sample, you can heat it with a laser or induction coil and measure the melting behavior without touching any container walls. This is especially valuable for research on ultra-high-purity titanium or for fundamental studies of the ti melting temperature.

- No contact with crucibles means zero contamination risk from container materials.

- Ideal for benchmarking the melting point of pure titanium or calibrating other measurement techniques.

- Requires specialized equipment but yields highly credible results for reference data.

Best practices for reliable reporting

- Always cite the measurement method (DSC, DTA, pyrometry, levitation) and calibration standards used.

- Report the sample’s composition, mass, and geometry—small differences can affect results.

- Specify the atmosphere (vacuum, argon, air) and crucible or container material.

- Include estimated uncertainty, especially for non-contact methods or when emissivity is variable.

- For alloys, report both solidus and liquidus temperatures, not just a single value.

Key takeaway: The most trustworthy titanium melting point data comes from well-calibrated instruments, transparent reporting, and a clear understanding of measurement uncertainties. Always check the source and method before relying on a published value.

By following these practices, you’ll be able to judge the quality of melting point data—whether you’re specifying materials for aerospace, medical, or advanced manufacturing. Up next, we’ll connect this measurement know-how to real-world manufacturing decisions, helping you choose the right process based on reliable thermal data.

From melting to making the right manufacturing route

When you’re choosing how to turn titanium—be it titanium grade 5, titanium grade 2, or ti6al4v—into a finished part, your understanding of the melting point is just the start. But how do you decide whether to cast, forge, print, or machine it? Let’s break down your options and make sense of which method fits best for your application, budget, and performance needs.

When to cast, forge, print, or machine titanium

Imagine you’re developing a high-performance aerospace bracket or a custom medical implant. Do you melt and cast the titanium, forge it for strength, print it for design freedom, or machine it for precision? Here’s a practical outline to guide your decision:

- Define your application: Does your part demand extreme strength (like a jet engine disk), intricate internal channels, or ultra-tight tolerances?

- Choose your alloy: Are you working with titanium grade 5 (Ti-6Al-4V), titanium grade 2, or another variant? Each responds differently to melting, forging, and machining due to its solidus/liquidus range and phase behavior (PMC9380981).

- Match process to geometry and performance: Complex, hollow shapes favor casting or additive; ultra-strong, safety-critical parts benefit from forging; and precision-critical or contamination-sensitive parts are best machined.

- Consider lead time and cost: Need parts fast, or only a few? Machining or additive might win. For large batches, casting or forging can be more cost-effective.

- Evaluate post-processing needs: 3D-printed and cast parts often require machining for final tolerances and surface finish.

Decision factors from melting range to tolerance

The melting range of titanium alloys directly impacts which manufacturing route is practical. For example, the solidus and liquidus temperatures of titanium 6al 4v (grade 5) mean precise temperature control is essential for casting or welding, while machining sidesteps these risks entirely. On the other hand, forging exploits the phase transformation regions below the melting point to achieve superior mechanical properties—but at the cost of higher tooling investment and process complexity.

Practical path from material to finished part

Let’s compare the major options for making titanium components, especially focusing on tolerance, design flexibility, cost, and lead time. Notice how CNC machining services like XTJ stand out for precision and speed—crucial when melting-based processes are impractical or too risky for your titanium grade 5 or titanium 6al 4v parts.

| Manufacturing Route | Best For | Tolerances | Design Flexibility | Lead Time | Cost Efficiency | Notes |

|---|---|---|---|---|---|---|

| XTJ CNC Machining | Precision parts, prototypes, low to mid-volume, aerospace/medical | Ultra-high (±0.005 mm) | Moderate (complex features with multi-axis) | Very short (as fast as 3 days) | High for small batches | No melting required; ideal for contamination-sensitive titanium grade 5 and grade 2 parts; ISO 9001:2015/IATF16949 certified |

| Forging | High-strength, load-bearing, safety-critical parts | High (depends on die and post-machining) | Limited (simple to moderately complex shapes) | Medium to long (tooling and process setup) | Efficient for medium to high volume | Superior mechanical properties; best for aerospace/automotive |

| Casting | Complex geometries, mass production | Moderate (post-machining often needed) | Very high (intricate internal features possible) | Medium (mold/tooling required) | Low per part for large volumes | Risk of porosity/defects; lower mechanical strength than forging |

| Additive Manufacturing (3D Printing) | Custom, complex, lightweight parts; rapid iteration | Moderate (post-machining for final fit/finish) | Very high (design freedom) | Short (especially for prototypes) | Best for low to medium volume | Surface roughness and microstructure may require machining |

Key takeaway: If your part demands ultra-tight tolerances, rapid turnaround, or contamination-free processing—such as for titanium grade 5 or titanium 6al 4v in aerospace or medical applications—CNC machining (like XTJ’s service) is often the most reliable route. For intricate shapes or mass production, casting or additive manufacturing may be preferable, but expect additional machining for critical surfaces. Forging remains the gold standard for strength and reliability, especially in demanding environments.

In summary, the right path from melting point knowledge to manufacturing success depends on your alloy, design, and performance needs. Up next, we’ll wrap up with actionable takeaways and trusted resources to help you move from process choice to part delivery with confidence.

Key takeaways and credible next steps for titanium melting point decisions

Key takeaways for engineers and buyers

Pure titanium melts at 1668 °C (3034 °F) under standard atmospheric pressure.

- Alloying elements like aluminum and vanadium shift the melting temp of titanium to a range (solidus to liquidus), so always check your specific grade.

- Phase behavior—the way titanium changes structure with temperature and composition—directly impacts process selection, from forging to casting to welding.

- Processing environment (vacuum, inert gas, crucibles) is critical to avoid contamination, especially when operating near the titanium melting temperature.

- Measurement methods such as DSC/DTA and pyrometry ensure you’re working with reliable data—always confirm sources and standards.

Trusted references to validate your numbers

- Huaxiao-Alloy: Melting Point of Titanium – Authoritative summary of melting points for pure titanium and common alloys.

- ASM Handbook: Additive Manufacturing of Titanium Alloys – Reference for alloy behaviors and processing implications.

- Fictiv: Titanium CNC Machining Guide – Practical insights into manufacturing and industry standards.

Next steps for titanium part production

- Verify the solidus/liquidus range for your specific alloy using ASM or AMS data sheets.

- Confirm interstitial limits (O, N, H, C) via material certification and pre-process analysis.

- Select the appropriate melt/process window based on phase diagram guidance and end-use requirements.

- Plan for quality assurance: Specify measurement methods, check supplier certifications, and document all process variables.

- If high-temperature processing or casting poses contamination or scheduling risks, consider precision CNC machining for titanium and Ti-6Al-4V parts. XTJ CNC machining services offer ultra-tight tolerances (±0.005 mm), rapid lead times, and ISO 9001:2015/IATF16949 certification—making them a strong option for aerospace and medical components where melting-based routes are less practical.

- Always compare vendors, request sample parts, and verify certifications before committing to any supplier or process.

In summary, knowing what is titanium's melting point is just the beginning. Your real-world success depends on integrating phase behavior, alloy selection, and process control with trusted data and qualified partners. Whether you’re specifying the titanium melting temperature for a new design or troubleshooting a manufacturing challenge, use these resources and action steps to move forward with confidence.

Titanium Melting Point FAQs

1. What is the melting point of pure titanium?

Pure titanium melts at 1668 °C (3034 °F, 1941 K). This high melting point makes titanium ideal for demanding applications in aerospace, medical, and industrial manufacturing where heat resistance is critical.

2. How do alloying elements affect the melting point of titanium?

Alloying elements like aluminum and vanadium lower the melting point of titanium and create a melting range (solidus to liquidus) instead of a single temperature. For example, Ti-6Al-4V (Grade 5) begins melting around 1604 °C and is fully liquid by 1660 °C, impacting casting, welding, and forging processes.

3. Why is atmosphere control important when melting titanium?

Titanium reacts easily with oxygen, nitrogen, and hydrogen at high temperatures, which can cause embrittlement or contamination. Using vacuum or high-purity inert gas atmospheres, along with non-reactive crucibles, helps maintain titanium's purity and mechanical properties during melting or welding.

4. What are the main industrial methods for melting titanium?

Key industrial melting methods include Vacuum Arc Remelting (VAR), Electron Beam Melting (EBM), Vacuum Induction Melting (VIM), and Cold Crucible Induction Melting (CCIM). Each method offers different levels of purity, scalability, and cost, with VAR and EBM commonly used for aerospace and medical-grade titanium.

5. When should CNC machining be chosen over melting-based processes for titanium parts?

CNC machining is preferred for titanium components requiring ultra-tight tolerances, rapid turnaround, or contamination-sensitive applications. It eliminates the risks of high-temperature contamination and is ideal for aerospace and medical parts, especially when working with Grade 5 or Grade 2 titanium.

-

Posted in

CNC machining titanium, manufacturing titanium, phase diagram, titanium alloys, titanium melting point