Does Titanium Rust Or Just Tarnish? Spot, Stop, And Prevent It

Does Titanium Rust?

Short answer: Does titanium rust?

When you invest in titanium—whether it’s a ring, a watch, a bike frame, or an engineering component—you want to know: does titanium rust? The simple answer is no, pure titanium does not rust like iron or steel. Instead of forming flaky, reddish-brown iron oxide (the classic sign of rust), titanium develops a thin, invisible layer of titanium oxide that protects it from further corrosion. This unique property makes titanium a top choice for jewelry, marine parts, implants, and many industrial applications [source].

Key takeaway: Pure titanium does not rust in the way iron-based metals do—it forms a protective oxide layer that keeps it safe in most everyday environments.

Rust vs corrosion vs tarnish: Know the difference

Sounds complex? Let’s break it down. "Rust" refers specifically to iron oxide—so only metals containing iron can truly rust. "Corrosion" is a broader term for the gradual breakdown of metals due to chemical reactions with their environment, like moisture or acids. "Tarnish" is a surface discoloration (often gray or dull) that happens to some metals, like silver, but doesn’t flake or erode the way rust does.

- Rust: Only affects iron and iron-containing alloys (like steel)

- Corrosion: Any chemical breakdown of metal (including rust, but also other reactions)

- Tarnish: Surface dulling or color change, usually cosmetic and not destructive

So, when you ask "does titanium rust or tarnish," what you’re really asking is whether titanium will suffer the same fate as other metals. The answer: titanium does not rust, and it is extremely resistant to tarnish and most forms of corrosion.

What happens in water and everyday use?

Imagine wearing your titanium ring in the shower, swimming in a pool, or taking your titanium watch to the beach. You’ll notice it keeps its shine and structure—because even in water, including saltwater, titanium forms that protective oxide film. This process, called "passivation," happens naturally and instantly when titanium is exposed to oxygen in air or water. That’s why you’ll find titanium used in marine propellers, medical implants, and chemical processing equipment.

- Passivation: Titanium self-heals its protective layer when scratched

- Re-oxidation: The oxide film reforms even after minor damage

- Everyday durability: Resistant to water, sweat, and most household chemicals

- Rare exceptions: In environments lacking oxygen (like a vacuum) or with aggressive chemicals, titanium can corrode, but this is uncommon in daily life

For consumers, this means titanium jewelry and watches are safe for everyday wear and water exposure. For engineers, it means titanium is a reliable choice in most service environments, though extreme cases (like oxygen-free or highly acidic conditions) require design consideration.

In summary, if you’re wondering "titanium does it rust" or "does titanium rust easily," rest assured: under normal conditions, titanium is exceptionally resistant. Later sections will dive deeper into care tips, rare exceptions, and advanced engineering insights. And if you’re still curious—does titanium.rust? The answer remains: not in the way you might expect.

Why Titanium Resists Rust

Passive Film Basics: The Invisible Shield

When you hear "does titanium rust or oxidize," it’s natural to wonder what’s really happening on the surface of this metal. Unlike iron, which forms crumbly rust, titanium instantly develops a thin, invisible shield called a passive oxide film—specifically, titanium dioxide (TiO2). Imagine a protective glass coating that forms the moment titanium touches air or water. This layer is just nanometers thick, but it’s incredibly stable and tightly bonded to the metal, acting as a barrier against moisture, salts, and most chemicals.

- Passive film: Self-forming, ultra-thin, and extremely stable

- Self-healing: Repairs itself instantly if scratched

- Chemical inertness: Resists acids, bases, and saltwater

- Low dissolution rate: Barely any metal is lost in most environments

- Chloride tolerance: Stands up to seawater and brackish water

Rapid Repassivation After Scratches: Titanium’s Self-Repair Trick

Ever scratched your titanium ring or watch and worried about damage? Here’s the science: as soon as the oxide film is disturbed—whether by abrasion, cut, or even chemical exposure—titanium reacts with the tiniest traces of oxygen or water to rebuild that film in seconds. This “repassivation” is why titanium’s surface rarely ever degrades, even with daily wear or in harsh settings. In fact, only a few aggressive chemicals (like hydrofluoric acid or hot, concentrated acids) can break this cycle in real-world conditions [source].

Titanium’s oxide film is not just a barrier—it’s a self-healing, adaptive shield. This is why, when people ask "does titanium rust or is it magnetic," the answer is: titanium doesn’t rust, and its protective layer is always regenerating.

Electrochemistry in Simple Terms: Why Titanium Doesn’t Rust Like Iron

Let’s get practical. Rust on iron forms because iron reacts with oxygen and water to create iron oxide, which flakes off and exposes fresh metal—leading to more rust. Titanium, by contrast, forms titanium dioxide, which sticks firmly and doesn’t flake. This difference is crucial: oxidation on titanium is protective, not destructive. That’s why, when you ask "does titanium corrode or rust," the answer is that titanium does oxidize, but this oxidation shields the metal rather than destroys it.

For engineers, the Pourbaix diagram (a pH vs. voltage map) shows that titanium remains passive and protected over a wide range of conditions—including most natural waters and environments. Only in extreme, oxygen-free, or highly acidic settings does the passive layer break down and allow actual corrosion. In almost all household, marine, and medical settings, titanium’s natural chemistry keeps it safe.

- Why does titanium have the ability to not rust? Because its oxidation is self-limiting and forms a stable barrier.

- Does titanium ever rust? Only in rare, highly aggressive conditions—not in daily use.

- Does titanium rust or oxidize? It oxidizes, but this process protects rather than harms the metal.

So, if you’re still wondering "does titanium rust or is it magnetic"—titanium’s magic is in its chemistry: it resists rust by building an invisible, self-healing shield. This is why it’s trusted for everything from medical implants to deep-sea equipment. Next, we’ll explore the rare cases where titanium’s corrosion resistance can be challenged, and what that means for both consumers and engineers.

Where Titanium Can Fail

Freshwater and Seawater Performance

When you’re considering titanium for jewelry, marine gear, or even industrial equipment, a common question is: does titanium rust in salt water or freshwater? The answer is reassuring—titanium and its alloys are exceptionally resistant to both. In natural waters and seawater, titanium forms a stable, protective oxide film that shields it from corrosion, even after years of exposure. For example, unalloyed titanium and Ti-6Al-4V (Grade 5) have shown nil or negligible corrosion rates after up to 16 years in polluted, sulfide-containing seawater and at ocean depths exceeding a mile. Marine deposits and fouling do not undermine this protection.

That’s why titanium is the material of choice for critical marine applications—everything from ship components to desalination plants. If you’re shopping for a kayaking knife, you might wonder, “does titanium blade rust kayak?” The answer is no—titanium blades are among the most corrosion-resistant options available for water sports, making them ideal for harsh, wet environments [reference].

Chlorides, Heat, and Crevices: The Real Risks

So, does titanium rust in saltwater or when wet? Under normal, well-aerated conditions—even in saltwater—titanium remains immune to general corrosion. However, the story changes in stagnant or low-oxygen crevices, especially at elevated temperatures (above 75°C/165°F). In these tight spaces, oxygen can’t reach the metal surface, preventing the passive film from reforming. This can lead to crevice corrosion, a localized attack that doesn’t affect open surfaces but can damage gaskets, flanges, or overlapping parts [reference].

For most users, this is not a concern—unless equipment design traps water in tight gaps. The risk increases with higher chloride concentrations (as in brines or hot seawater), lower pH (more acidic), and rising temperatures. But even then, titanium’s resistance is impressive: crevice corrosion is generally not observed below 70°C (158°F) in seawater, and advanced alloys (like those with palladium) push this threshold even higher.

| Environment | Risk Level | Typical Issue | Mitigation |

|---|---|---|---|

| Freshwater (all types) | Low | Surface discoloration at high temp | None needed; normal cleaning |

| Seawater (well-aerated) | Very Low | None; negligible corrosion | Standard design |

| Seawater (stagnant crevice, >75°C/165°F) | Moderate | Crevice corrosion possible | Avoid tight crevices; use flow; select appropriate gaskets |

| Hot reducing acids (e.g., hydrochloric, sulfuric) | High | General corrosion, rapid attack | Avoid; use specialty alloys or inhibitors |

| Halogen-rich hot gases (chlorine, bromine, fluorine) | High | Film breakdown, rapid corrosion | Not recommended for titanium |

| Hydrogen-rich, low-pH environments | Moderate | Hydride formation (embrittlement) | Control pH, avoid galvanic coupling to active metals |

Specific Chemicals to Watch

While titanium resists most chemicals, it is vulnerable to certain aggressive agents. Hydrofluoric acid (even diluted), hot concentrated reducing acids, and halogen gases (especially dry chlorine or fluorine) can destroy the passive film and cause rapid attack. In these cases, titanium is not recommended. For most household and marine uses, however, these chemicals are rarely encountered.

How long does it take for titanium to rust? In nearly all natural and industrial waters, the answer is “practically never”—corrosion rates are so low they’re measured in microns per year, and titanium components have been documented to last decades in seawater without measurable loss. Even when titanium is wet or exposed to salt spray, the protective film reforms instantly, so “does titanium rust when wet” is a non-issue for real-world use.

- Avoid stagnant or low-flow zones in design

- Insulate titanium from dissimilar metals to prevent galvanic issues

- Choose a smooth surface finish to minimize crevice formation

- For kayak enthusiasts: selecting a titanium blade ensures your gear won’t rust, even in saltwater—so if you’re asking “does titanium blade rust kayak,” you can paddle worry-free

For engineers and designers, always assess the specific service environment: consider temperature, water chemistry, flow, and possible crevices. For consumers, titanium’s legendary durability means your jewelry, watches, and outdoor gear will withstand water, sweat, and even the ocean for years to come. The next section will explore how different titanium grades and alloys compare in their corrosion resistance, so you can make the best choice for your needs.

Why Titanium’s Corrosion Resistance Varies

CP Grades 1 to 4: The Workhorses of Everyday Corrosion Resistance

Ever wondered if all titanium is created equal when it comes to corrosion resistance? Let’s break it down: the most common forms you’ll encounter are the commercially pure (CP) titanium grades 1 to 4. These grades are essentially unalloyed, with only trace amounts of elements like oxygen, nitrogen, and iron. Their biggest strength? Outstanding corrosion resistance in almost any natural or industrial water environment.

- Grade 1: The softest and most ductile—ideal for applications needing easy forming (think heat exchangers or chemical linings).

- Grade 2: The most widely used CP grade, balancing formability and strength. It’s a favorite for marine hardware, piping, and medical devices.

- Grades 3 and 4: Progressively stronger, used where higher mechanical strength is needed, like pressure vessels or high-stress fittings.

So, does pure titanium rust? In practical terms, no. These grades form that same self-healing oxide layer described earlier, which is why “does raw titanium rust” or “titanium wire grade 1 1mm diameter does it rust” are questions with reassuring answers: even thin wires and exposed surfaces resist corrosion in air, water, and most chemicals.

| Grade | Microstructure | Typical Applications | Corrosion Notes |

|---|---|---|---|

| CP Grade 1 | Alpha | Heat exchangers, linings, wire | Best formability, excellent corrosion resistance |

| CP Grade 2 | Alpha | Piping, marine parts, medical | Outstanding corrosion resistance; most common CP grade |

| CP Grade 3 | Alpha | Pressure vessels, industrial | Higher strength, still excellent corrosion resistance |

| CP Grade 4 | Alpha | Aircraft, high-stress parts | Strongest CP grade, very good corrosion resistance |

Ti 6Al-4V (Grade 5): The High-Strength All-Rounder

Now, what about alloys—does titanium alloy rust? The most famous is Ti 6Al-4V (Grade 5), an alpha-beta alloy containing aluminum and vanadium. This grade is the global leader for aerospace, medical implants, and high-performance sporting goods. It’s chosen for its superior strength-to-weight ratio and good weldability.

But does grade 5 titanium rust? In almost all water and atmospheric conditions, it remains highly resistant, thanks to the same protective oxide film. However, compared with CP grades, Grade 5 can be slightly more susceptible to localized corrosion (like crevice or pitting) in very aggressive environments—especially if fabrication leaves rough surfaces, weld discoloration, or tight crevices. For most users—whether it’s a bike frame, implant, or industrial part—this is a non-issue. Proper finishing and cleaning after welding restore full corrosion resistance.

| Grade | Microstructure | Typical Applications | Corrosion Notes |

|---|---|---|---|

| Grade 5 (Ti 6Al-4V) | Alpha-Beta | Aerospace, medical, sports, marine | Very good corrosion resistance; watch for crevices or weld tint |

Other Alpha-Beta and Beta Alloys: Specialized Performance

Looking for something even more specialized? Titanium alloys like Grade 7 (CP with added palladium) and Grade 12 (with nickel and molybdenum) are engineered for tough chemical environments, offering even greater resistance to reducing acids or crevice corrosion. Beta and near-beta alloys (like Ti-13V-11Cr-3Al) are used where high strength or fatigue resistance is critical, such as advanced aerospace or biomedical implants.

| Grade | Microstructure | Typical Applications | Corrosion Notes |

|---|---|---|---|

| Grade 7 | Alpha (with Pd) | Chemical processing, seawater | Superior crevice and acid resistance |

| Grade 12 | Alpha-Beta (with Ni, Mo) | Heat exchangers, aggressive media | Enhanced resistance to reducing acids |

Surface Finish, Processing, and Small Diameters: What to Watch For

Imagine a titanium wire—Grade 1, 1mm diameter—exposed to seawater. Does it rust? Not under normal conditions. But if the surface is rough, contaminated, or if the wire is bundled tightly (creating crevices), localized corrosion risk can increase, especially in hot, stagnant, or polluted environments. The same goes for welds: heat tint or improper cleaning can disrupt the oxide film, but this is easily remedied with post-weld pickling or polishing.

- For best performance: Specify smooth finishes, avoid tight crevices, and clean welds properly.

- For consumers: Whether you’re buying a titanium ring, wire, or bike, “does titanium alloy rust” or “does raw titanium rust” is not a practical concern for daily use.

Pure and alloyed titanium grades all rely on a protective oxide film—so in normal use, neither rust nor destructive corrosion is a concern. Grade, surface finish, and design details only matter in the harshest environments.

Next, we’ll move from understanding material choices to practical care and inspection—so you can keep your titanium gear looking and performing its best for years to come.

How to Keep Titanium Jewelry and Parts Flawless

Everyday Care for Jewelry and Watches

Ever wondered why your titanium ring or watch still shines after years of daily wear? The secret is titanium’s natural resistance to tarnish and corrosion. But even though "does titanium jewelry rust" is rarely a concern, a little routine care goes a long way to keep your pieces looking their best [The Chubby Paw].

- Do: Clean with mild soap and warm water. Use a soft cloth or toothbrush to gently remove dirt and oils.

- Do: Rinse thoroughly and dry with a lint-free towel to prevent water spots.

- Do: Store pieces separately in soft pouches or lined boxes to avoid scratches.

- Don’t: Use bleach, harsh chemicals, or abrasive pads—they can damage finishes or decorative elements.

- Don’t: Mix titanium jewelry with harder metals in storage; this prevents accidental scratches.

If you’re asking, "does titanium earrings rust" or "does titanium ring rust," rest assured: with proper care, these items will remain corrosion-free. For extra shine, a quick buff with a microfiber cloth or a dab of olive oil works wonders. Avoid ultrasonic cleaners, as they can sometimes damage surface treatments or inlays.

Light Industrial Maintenance Routines

For engineers or anyone maintaining titanium equipment, the same principles apply—just scaled up. Regular cleaning removes contaminants that might compromise the protective oxide film. Here’s a simple protocol:

- Wipe down surfaces with a soft cloth and a mild soap solution.

- Rinse thoroughly with clean water to remove residues.

- Dry immediately with a clean, soft towel to prevent water spots.

- Inspect for signs of wear, discoloration, or deposits—especially after use in harsh environments.

- If exposed to saltwater or chemicals, clean as soon as possible to avoid buildup.

For critical parts, consider applying a protective coating or consulting a professional for ultrasonic cleaning and polishing.

Key tip: Removing everyday contaminants and allowing the titanium’s passive oxide film to breathe is the simplest way to keep it looking and performing its best.

What to Do After Exposure to Water, Salt, or Chemicals

Imagine you’ve just returned from the beach or finished a tough day in the shop. What now? While "does titanium watch rust" or "does titanium piercings rust" are common worries, the answer is almost always no—if you follow a few simple steps:

- Rinse titanium items with fresh water after saltwater or chemical exposure.

- Dry thoroughly to prevent mineral deposits or water spots.

- Inspect for any surface changes—address with gentle cleaning if needed.

- For jewelry, polish with a soft cloth to restore shine.

- If stubborn stains or scratches appear, use a non-abrasive titanium polish or seek professional help.

For regular inspection, set a monthly reminder for jewelry and a post-use check for industrial parts. You’ll catch minor issues before they become problems, ensuring that "does titanium rings rust" remains a question with a reassuring answer: Not when you care for them right.

By following these simple protocols, you’ll enjoy the legendary durability and beauty of titanium—whether it’s on your finger, wrist, or in the engine room. Next up, we’ll troubleshoot what to do if you ever spot discoloration or surface changes, so you can act quickly and confidently.

What to Do When Titanium Turns Color

Color Changes and What They Mean

Ever noticed your titanium ring looking a little dull, or your anodized bolts losing their vibrant color? You might wonder: does titanium tarnish or rust, or is something else going on? The good news is, true rust—the reddish flaking you see on iron—doesn’t form on titanium. But titanium can show a variety of color changes, each with its own cause and simple fix.

- Heat tint: Straw, purple, or blue hues that appear after exposure to high temperatures (like welding or torching).

- Anodized color loss: Fading or dulling of bright colors, often caused by oils from skin or mild surface contamination.

- Gray film or dullness: Usually a buildup of deposits (soap, minerals, or oils), not corrosion or tarnish.

- Dark spots or rare pitting: Can indicate aggressive chemical exposure, crevice corrosion, or contamination—but this is extremely rare in daily use.

Diagnose Before You Treat

Sounds complex? It’s really about observation. Ask yourself: Has the item been exposed to heat, chemicals, or just daily wear? Did the color change suddenly, or gradually over time? Here’s a practical troubleshooting table to help you identify and address the most common issues:

| Symptom | Likely Cause | Diagnostic Step | Recommended Remediation |

|---|---|---|---|

| Straw/blue/purple tint | Heat exposure (welding, torch, friction) | Recall any recent heating or processing | Polish gently with non-abrasive pad; for deep tints, consider professional refinishing |

| Dull or faded anodized colors | Oils, fingerprints, light contamination | Check for residue; wipe with clean cloth | Wash with mild soap and water, dry with microfiber; use isopropyl alcohol for stubborn oils |

| Gray film or spots | Mineral or soap deposits | Try gentle cleaning; see if film lifts | Soak in warm, soapy water; use soft toothbrush, rinse and dry thoroughly |

| Dark spots/pitting (rare) | Harsh chemicals, crevice corrosion | Inspect environment for aggressive agents | Remove deposits, avoid further exposure; consult specialist for severe cases |

Restore Finish Safely

Imagine you’re cleaning your favorite titanium watch or anodized bike part. The best approach is always the gentlest one first. Here are the steps that work for almost any discoloration:

- Step 1: Rinse with warm water to remove loose debris.

- Step 2: Wash with mild dish soap and a soft cloth or toothbrush. This removes most oils and everyday grime.

- Step 3: For anodized titanium, use isopropyl alcohol or Windex to restore color vibrancy, then dry with a clean microfiber cloth.

- Step 4: For persistent heat tint or stubborn marks, use a non-abrasive polishing pad—never steel wool or harsh chemicals, which can damage the protective oxide layer or strip anodized colors.

- Step 5: If color loss or pitting persists, seek professional re-anodizing or refinishing.

Rule of thumb: Always start with gentle cleaning—escalate to surface treatments only if basic washing doesn’t restore the finish. Avoid steel wool, abrasive pads, or bleach, as these can do more harm than good.

So, does titanium ever tarnish rust, or turn dark like magnetic metals? Not in the way iron or silver does. Most changes are cosmetic and reversible with simple care. If you’re wondering "does anodized titanium rust" or "does.titanium rust," the answer remains: titanium’s surface changes are not true rust—they’re either heat effects, deposits, or environmental films, not destructive corrosion.

By understanding these cues and using the right cleaning methods, you’ll keep your titanium gear looking sharp and performing at its best. Next, we’ll clear up confusion around “titanium steel” and compare how titanium stacks up against stainless steel and other alloys in daily wear.

Titanium Versus Titanium Steel and Stainless Clarified

What Does “Titanium Steel” Mean in Jewelry and Accessories?

Ever seen a ring or necklace labeled “titanium steel” and wondered what you’re really buying? The term can be confusing, especially since it sounds like a blend of two super metals. In jewelry retail, “titanium steel” is most often a marketing term for stainless steel—typically the 316L grade—rather than a true alloy of titanium and steel. Actual titanium steel alloys (where both metals are intentionally combined) are rare in consumer products. If you’re searching for answers to “titanium steel does it rust” or “does titanium steel necklace rust,” it’s important to know what’s in your jewelry before assessing its long-term durability.

Titanium vs Stainless Steel: Corrosion and Tarnish in Daily Wear

So, does titanium steel rust, or is it just a myth? Let’s break down the science. Titanium is a pure element with a natural ability to form a protective oxide film, making it highly resistant to corrosion, tarnish, and rust—even in harsh environments. Stainless steel, on the other hand, is an alloy of iron, chromium, nickel, and sometimes molybdenum or titanium. Its corrosion resistance comes from a chromium oxide layer, which is tough but not as robust as titanium’s oxide barrier.

Here’s how these materials compare in the real world—think jewelry, watches, and accessories exposed to water, sweat, or salt:

| Material | Typical Composition Note | Water & Sweat | Saltwater | Pros | Considerations |

|---|---|---|---|---|---|

| Titanium | Pure metal, sometimes alloyed for strength | Exceptional resistance; no rust or tarnish | Outstanding; rarely affected | Lightweight, hypoallergenic, highly durable | More expensive, can scratch more easily than steel |

| Stainless Steel (316L) | Iron, chromium, nickel, molybdenum | Very good; generally doesn’t rust, but can tarnish over time | Resistant, but may pit in tight crevices or with prolonged exposure | Affordable, scratch-resistant, easy to shape | Heavier than titanium, less hypoallergenic, can show wear in harsh conditions |

| “Titanium Steel” (retail term) | Usually stainless steel, sometimes with trace titanium | Same as stainless; good, but not as inert as pure titanium | May corrode in extreme or poorly maintained environments | Looks modern, low maintenance, budget-friendly | Check actual composition; not pure titanium |

So, does titanium steel jewelry rust or tarnish? In most daily scenarios, stainless steel (and thus “titanium steel”) holds up well—especially if you avoid harsh chemicals and keep it clean. However, if you’re after the highest corrosion resistance and minimal maintenance, pure titanium is the clear winner. For those wondering, “does titanium steel rust in water,” the answer is generally no for short-term or gentle exposure, but over years and with repeated contact, minor tarnish or pitting can occur—especially if the surface is scratched or exposed to saltwater [Inspereza].

When Is Each Material the Better Choice?

Choosing between titanium, stainless steel, and titanium steel depends on your priorities—weight, cost, skin sensitivity, and exposure to moisture. Here are some quick rules of thumb:

- If you want maximum corrosion resistance, lightness, and hypoallergenic properties, choose pure titanium.

- For affordability and scratch resistance, stainless steel (or “titanium steel”) is a strong everyday option.

- If you’re concerned about long-term exposure to sweat or seawater, titanium is less likely to discolor or corrode.

- Always check what “titanium steel” means in the product description—don’t assume it’s pure titanium.

Key takeaway: Pure titanium almost never rusts or tarnishes, even in tough environments. Stainless steel (and “titanium steel”) is durable for most uses, but may show minor wear or tarnish over time—especially in saltwater or if the surface is scratched. When in doubt, check the composition and care instructions for your jewelry or accessory.

To sum up, if you’re asking “does titanium steel rings rust” or “does titanium steel necklace rust,” know that these items are usually made from quality stainless steel and will resist rust under normal use, but aren’t as maintenance-free as pure titanium. Next, we’ll guide engineers and designers through selecting the right material for challenging environments—so you can match performance to your needs.

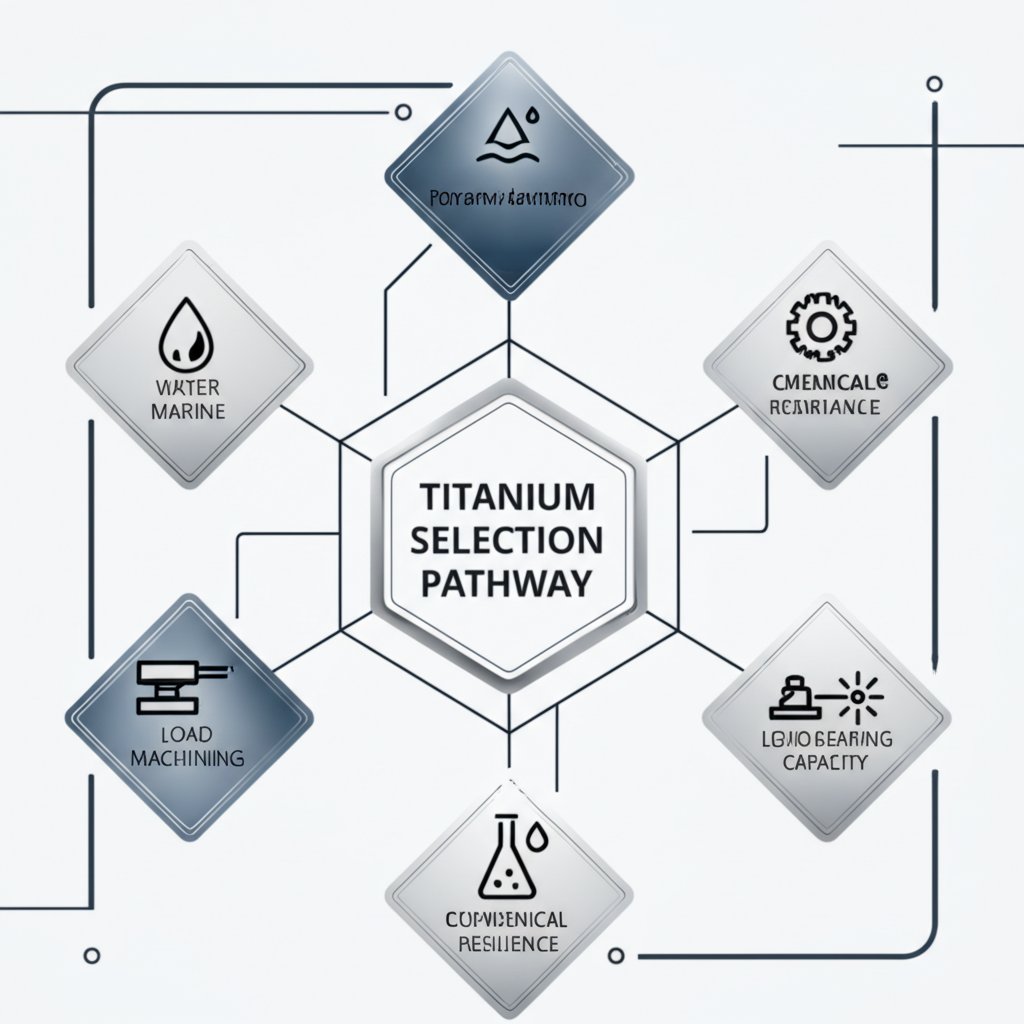

Design Decision Pathway

Decision Path by Environment and Mechanical Needs

When you’re designing a part that must resist corrosion, the question isn’t just “does titanium metal rust?”—it’s whether titanium is the right fit for your specific environment, load, and manufacturing process. Here’s a stepwise decision tree to guide your choice, whether you’re developing a saltwater valve, a medical implant, or a high-performance exhaust:

-

Define the Service Environment

- Is the part exposed to chlorides (saltwater, sweat, brine)?

- Will it face high temperatures (e.g., exhaust, chemical processing)?

- Are crevices, stagnant zones, or low-oxygen pockets unavoidable?

-

Assess Mechanical and Functional Requirements

- Does the application demand high strength, fatigue resistance, or flexibility?

- Is lightweight design a priority?

- Will the part undergo repeated loading (e.g., blades, springs)?

-

Evaluate Fabrication and Joining

- Will the part be welded, machined, or formed?

- Are ultra-tight tolerances or intricate geometries required?

- Does the design call for joining titanium to other metals (e.g., aluminum, copper)?

-

Balance Cost, Availability, and Certification

- Is titanium’s higher material cost justified by its service life?

- Are industry certifications or traceability required (e.g., medical, aerospace)?

- Will rapid prototyping or small-batch production be needed?

-

Finalize Material and Manufacturing Path

- If titanium is optimal, select the grade (CP, Grade 5, or specialty alloy) and specify surface finish and tolerances.

- If a precision partner is needed, choose a CNC machining service with deep titanium experience. For example, XTJ offers 4- and 5-axis machining with tolerances down to +/- 0.005mm, rapid lead times, and support across more than 30 materials—including titanium, aluminum, and copper. Their engineering support can help you optimize geometry and finish to minimize corrosion risks and manufacturing defects.

Surface Finish and Geometry Considerations

Even the best titanium alloy can suffer from crevice attack or galvanic corrosion if design details are neglected. Here are some actionable mitigations if you choose titanium:

- Avoid tight crevices and stagnant water zones—design for easy drainage and cleaning.

- Specify a smooth, pickled, or polished finish to reduce deposit buildup and facilitate oxide film formation.

- Isolate titanium from less noble metals like copper or brass (especially in saltwater) to prevent accelerating the corrosion of the other metal due to galvanic effects.

- For welded assemblies, ensure post-weld cleaning to remove heat tint and restore passivation.

- Consider coatings (like titanium nitride) for wear surfaces, but remember: while TiN is hard and chemically inert, it’s the underlying titanium that provides true corrosion resistance—so “does titanium nitride rust” is rarely a concern unless the coating is breached.

From Prototype to Production

Imagine moving from CAD to a finished titanium blade, exhaust, or implant. The right manufacturing partner can make the difference. CNC machining of titanium requires robust tooling, cooling, and fixture design to prevent heat buildup and distortion. XTJ’s advanced machining centers and material selection support help ensure that your final part meets both performance and corrosion requirements—whether you need a single prototype or a production run.

- Optimize wall thickness and radii to minimize stress risers and crevice formation.

- Validate fit and finish with rapid prototypes before committing to volume production.

- Document all surface treatments, heat treatments, and cleaning protocols for traceability—especially for medical or aerospace parts.

Key insight: The answer to "does titanium rust aluminum, exhaust, or blade" is almost always no—if you select the right alloy, finish, and manufacturing process for your application.

By following this structured pathway and leveraging expert CNC partners like XTJ for titanium and its alternatives, you can design parts that deliver long-term corrosion resistance and mechanical performance. In the next section, we’ll discuss how to validate your choices with standardized corrosion testing and actionable recommendations for ongoing quality assurance.

How to Validate Titanium’s Corrosion Resistance

Relevant Standards and What They Tell You

When you’re selecting titanium for a demanding application—whether for medical implants, marine hardware, or eyewear frames—it’s natural to ask: how do I know it won’t corrode in my environment? Or, if you’re considering a medical device, you might wonder, “does titanium rust in the body?” The answer depends on both the material and the validation process. Fortunately, a suite of recognized testing standards exists to help engineers, manufacturers, and even consumers ensure that titanium’s legendary corrosion resistance is up to the task.

| Test Family | What It Evaluates | When To Use | Notes |

|---|---|---|---|

| ASTM G-Series (e.g., G5, G59, G61) |

Electrochemical corrosion (polarization, pitting, passivation) | Material selection, environment mapping, alloy comparison | Widely used for basic corrosion characterization—ideal for comparing titanium to alternatives in water, saline, or body fluids |

| ASTM F-Series (e.g., F2129) |

Corrosion of medical implants (simulated body fluids, cyclic polarization) | Medical device qualification, implant design | Critical for answering “does titanium rust in your body”—these tests mimic physiological conditions |

| ISO 10271, ISO 10993-15 | Corrosion of dental/medical materials, biocompatibility | Dental, surgical, and implantable devices | Assures safety for long-term contact with the body |

| ASTM B117 (Salt Spray) | Accelerated atmospheric corrosion (salt fog) | Marine, eyewear, automotive, outdoor products | Useful for screening “does titanium glasses rust” or for marine hardware; titanium typically shows negligible attack |

| ISO, NACE MR0175 | Corrosion in oil & gas, chemical, and industrial environments | Pipelines, valves, process equipment | Ensures titanium alloys withstand aggressive chemicals and sour service |

Test Planning and Acceptance Ideas

Sounds technical? Here’s how to approach it. For most consumer and engineering applications, the goal is to simulate the real environment as closely as possible. For example, if you’re evaluating “does titanium rust or corrode” in the body, select a test that uses simulated body fluids and cyclic polarization (ASTM F2129). For eyewear or marine parts, salt spray (ASTM B117) or immersion tests in seawater are common. Electrochemical methods (ASTM G-series) offer rapid, quantitative comparisons between titanium and other metals—especially useful during materials selection or when optimizing surface treatments.

- Define the environment: temperature, pH, chemicals, oxygen levels.

- Choose the closest standard or customize a protocol based on real-world exposures.

- For critical parts (like implants or high-value equipment), request full documentation of test results and acceptance criteria.

- For prototypes or custom geometries, consider rapid testing with corrosion coupons or electrochemical cells.

Actionable Next Steps

Imagine you’re moving from design to production and want to minimize the risk of unexpected corrosion—especially in sensitive applications like medical devices or marine gear. Here’s a practical checklist to ensure your titanium parts deliver:

- Consult with experienced engineers during DFM (design for manufacturability) to optimize geometry and surface finish for corrosion resistance.

- Validate new designs with rapid prototypes—XTJ’s CNC machining services can deliver titanium parts with ultra-tight tolerances and documented surface finishes, helping you test real-world performance before full-scale production.

- Specify relevant standards (ASTM, ISO, NACE) in your procurement and quality assurance documents.

- For high-risk or regulated applications, require third-party or in-house testing according to the standards above.

- Keep a record of all test results, surface prep, and cleaning protocols—especially for parts exposed to body fluids, saltwater, or aggressive chemicals.

Bottom line: Titanium’s passivity and self-healing oxide film make it remarkably resistant to corrosion in most environments—including the body and marine settings. But the best way to guarantee performance is to validate your design with standardized tests, expert machining, and thoughtful material selection.

By following these steps—and leveraging resources like XTJ for rapid prototyping and engineering support—you can confidently answer “does titanium rust in the body,” “does titanium glasses rust,” or “does titanium rust or corrode” with real data, not just reputation. This approach ensures your titanium products meet the highest standards of durability and safety, no matter where they’re used.

Frequently Asked Questions About Titanium and Rust

1. Does titanium rust in water or saltwater?

Titanium does not rust in water or saltwater due to its self-healing oxide layer. Even after years of exposure, titanium remains highly resistant to corrosion in marine and freshwater environments, making it ideal for jewelry, watches, and marine equipment.

2. Can titanium jewelry or rings rust or tarnish?

Pure titanium jewelry and rings are exceptionally resistant to rust and tarnish. The protective oxide coating prevents corrosion and keeps items looking new, even with daily wear and exposure to sweat or water. Only in rare, extreme conditions might discoloration occur, which is usually reversible with gentle cleaning.

3. What is the difference between titanium, stainless steel, and titanium steel in terms of rust?

Pure titanium forms a durable, self-healing oxide layer that prevents rust, while stainless steel relies on chromium oxide for corrosion resistance but may still tarnish or pit over time, especially in saltwater. 'Titanium steel' is typically a marketing term for stainless steel and not pure titanium, so its rust resistance is similar to stainless, not titanium.

4. Are there any environments where titanium can corrode or fail?

Titanium is highly resistant in most natural settings, but can corrode in aggressive chemicals like hydrofluoric acid, hot concentrated acids, or in low-oxygen crevices at high temperatures. Proper design and cleaning help minimize these rare risks for both consumer and industrial applications.

5. How should I care for and clean titanium products to prevent discoloration?

Clean titanium with mild soap, warm water, and a soft cloth. Rinse and dry thoroughly, especially after saltwater exposure. Avoid bleach, harsh chemicals, or abrasive pads. For stubborn stains, use a non-abrasive polish or seek professional care. Regular inspection ensures long-lasting shine and performance.

-

Posted in

does titanium rust, rust prevention, titanium corrosion, titanium jewelry care, titanium vs stainless steel