Mastering Design for Manufacturability: An Essential Guide

TL;DR

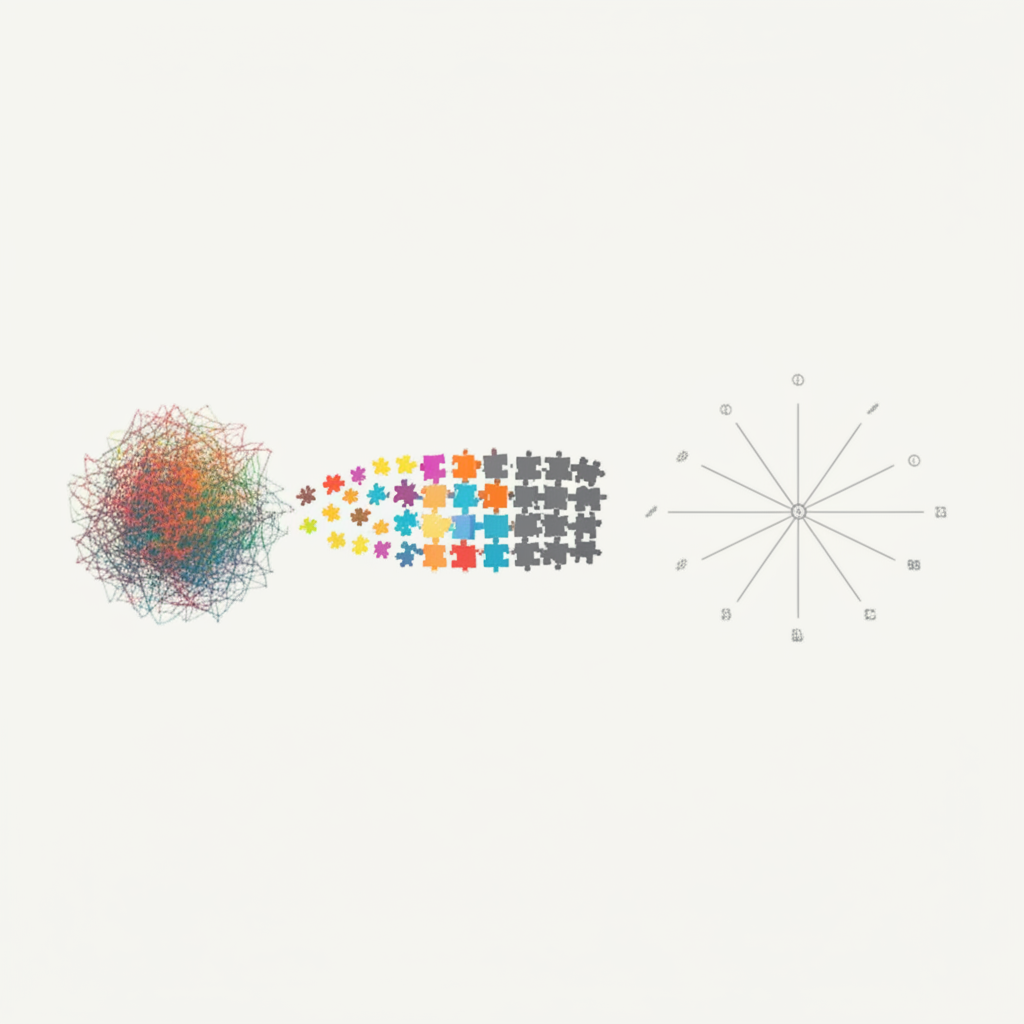

Design for Manufacturability (DFM) is an engineering methodology focused on intentionally designing products for ease and cost-effectiveness of production. The core objective is to create a superior product at a lower cost by simplifying the design, standardizing components, and considering the manufacturing process from the earliest stages. This proactive approach helps prevent costly downstream changes, accelerates time-to-market, and significantly improves overall product quality.

Understanding the Core Principles of DFM

Design for Manufacturability is built on a foundation of principles that guide engineers and designers toward creating products that are not only functional but also efficient to produce. By integrating manufacturing insights early in the design phase, companies can avoid common pitfalls that lead to delays and budget overruns. According to experts at East West Manufacturing, about 70 percent of a product's manufacturing costs are determined during the design phase, highlighting the critical importance of these principles. Adopting a DFM mindset means shifting from merely designing a functional part to engineering a successful, profitable product.

The primary goal is to streamline the path from concept to reality. This involves a cross-functional collaboration between designers, engineers, and manufacturing specialists to challenge and refine the design. The process examines every element to ensure it contributes to the product's function without adding unnecessary complexity or cost. The key is to embed manufacturability into the design's DNA.

Several foundational principles are central to effective DFM. These guidelines help teams focus their efforts on changes that deliver the most significant impact on cost, quality, and efficiency.

- Reduce the Number of Parts: Simplifying a product by minimizing its part count is one of the most effective ways to reduce costs. Fewer parts mean less material, simplified assembly, reduced inventory, and fewer potential points of failure. This often involves designing multi-functional components that serve several purposes at once.

- Use Standard Components: Opting for off-the-shelf, standard components instead of custom-designed ones drastically cuts down on cost and lead times. Standard parts are produced in high volumes, benefit from economies of scale, and have predictable quality and performance, as noted by sources like SixSigma.us.

- Design for Ease of Fabrication: The design should align with the capabilities of the chosen manufacturing process. This includes using constant wall thicknesses for molded parts to ensure uniform cooling, adding appropriate draft angles to prevent parts from sticking in molds, and avoiding features like undercuts that complicate tooling.

- Create Modular Designs: Designing products with modular assemblies allows for greater flexibility. It enables easier customization, simplifies repairs and upgrades, and allows different product lines to share common modules, streamlining both production and inventory management.

Key Factors to Consider in Your Design Process

Beyond the core principles, several critical factors must be evaluated during the design process to ensure a part is truly optimized for manufacturing. These considerations bridge the gap between a theoretical design and a physically producible product, addressing the practical realities of production. Neglecting these factors can lead to manufacturability issues, cost overruns, and quality problems down the line.

Material Selection

Choosing the right material is a cornerstone of DFM. The decision should be based on a balance of functional requirements, cost, and compatibility with the manufacturing process. Designers must consider mechanical properties (strength, durability), thermal properties (heat resistance), and electrical properties. Using common, readily available materials can help control costs and ensure a stable supply chain. It's also crucial to select materials that your existing or intended manufacturing equipment can handle efficiently.

Manufacturing Processes

The choice of manufacturing process—such as injection molding, sheet metal fabrication, or CNC machining—has profound implications for the design. Each process has unique capabilities and constraints. For example, a part designed for injection molding must incorporate features like draft and uniform wall thickness, while a machined part requires consideration for tool access and clearance. For projects requiring high-precision components, collaborating with a specialized provider is crucial. For instance, services like those from XTJ, which offer advanced 4 and 5-axis CNC machining, can produce complex parts with tight tolerances, making them a viable option to consider early in the design process when specific manufacturing capabilities are required.

Tolerances and Specifications

Tolerances define the acceptable variation for a part's dimensions. While tight tolerances are sometimes necessary for critical functions, over-tolerancing is a common and costly mistake. As explained by GD&T Basics, unnecessarily tight tolerances increase manufacturing difficulty, leading to higher scrap rates and increased costs. Using Geometric Dimensioning and Tolerancing (GD&T) helps focus on the functional requirements of the part, allowing for looser, more manufacturable tolerances where possible without compromising performance.

A Step-by-Step Approach to Implementing DFM

Implementing Design for Manufacturability is a structured process that integrates production considerations into every stage of product development. By following a systematic approach, teams can ensure that no detail is overlooked and that the final design is truly optimized for production. This proactive method helps catch potential issues early, when they are least expensive to fix.

- Collaborate Early and Often: The DFM process should begin at the concept stage. Assemble a cross-functional team that includes design engineers, manufacturing engineers, quality assurance specialists, and even material suppliers. This early collaboration ensures that diverse perspectives and expertise are incorporated from the start, preventing siloed thinking.

- Select the Right Manufacturing Process: Based on factors like production volume, material choice, and part complexity, determine the most suitable manufacturing process. This decision will heavily influence subsequent design choices. For example, a low-volume part might be better suited for 3D printing, while a high-volume part may require investment in tooling for injection molding.

- Simplify and Refine the Design: With the process selected, focus on simplifying the design. Challenge every feature and component: Is it necessary? Can it be combined with another part? Can it be made from a more cost-effective material? This stage involves applying core DFM principles like reducing part count and using standard components.

- Analyze and Iterate with DFM Tools: Utilize CAD software and specialized DFM analysis tools to simulate the manufacturing process. These tools can identify potential issues such as inconsistent wall thickness, difficult-to-machine features, or areas prone to defects. Use this feedback to iterate on the design until it is optimized.

- Develop Prototypes and Test: Before committing to expensive production tooling, create prototypes to validate the design. Prototyping allows you to test the part's form, fit, and function in the real world. It also provides an opportunity to test the assembly process and uncover any unforeseen challenges.

- Finalize Documentation and Handoff: Once the design is validated, create comprehensive documentation, including detailed drawings with appropriate GD&T, material specifications, and quality standards. Clear communication ensures that the manufacturing team can produce the part exactly as intended.

The Connection Between DFM and Design for Assembly (DFA)

While Design for Manufacturability (DFM) focuses on making individual parts easy and economical to produce, Design for Assembly (DFA) concentrates on making the final product easy and economical to assemble. The two concepts are deeply intertwined and are often combined into a single methodology known as Design for Manufacturing and Assembly (DFMA). A product composed of perfectly manufactured parts is of little value if those parts cannot be assembled efficiently and correctly.

DFA seeks to reduce assembly time and cost by minimizing the number of assembly steps, reducing the need for specialized tools, and designing parts that are easy to handle and orient. For example, a DFA principle is to design parts that are symmetrical to avoid incorrect insertion or use features like tabs and slots that make alignment self-guiding. According to Launchpad, the preferred assembly method is often a vertical stack, where gravity assists the process.

The synergy between DFM and DFA is powerful. A design change made to improve manufacturability (DFM) might inadvertently complicate assembly (DFA), or vice versa. By considering both simultaneously, teams can find an optimal balance. For example, combining two parts into one (a DFM principle) also eliminates a fastening step (a DFA principle), resulting in savings in both manufacturing and assembly.

| Aspect | Design for Manufacturability (DFM) | Design for Assembly (DFA) |

|---|---|---|

| Primary Focus | Individual component parts | The process of joining parts together |

| Key Goal | Reduce the cost of manufacturing each part | Reduce the cost and time of assembly |

| Typical Considerations | Material selection, tolerances, process capabilities, wall thickness | Part count, fasteners, handling, orientation, insertion |

| Example Principle | Simplify a part's geometry to make it easier to mold or machine. | Use snap-fits instead of screws to eliminate a fastening operation. |

Frequently Asked Questions

1. How to design for manufacturability?

To design for manufacturability, you should focus on simplifying the product design, standardizing components, selecting appropriate materials, and considering the manufacturing process from the very beginning. Key steps include reducing the total number of parts, using off-the-shelf components where possible, designing for ease of fabrication, and collaborating closely with manufacturing engineers throughout the development cycle.

2. What five factors play a part in design for manufacturability?

Five critical factors in DFM are: 1) Minimizing part count to reduce complexity and cost. 2) Standardizing parts and materials to leverage economies of scale and simplify inventory. 3) Designing for the chosen manufacturing process and its capabilities. 4) Specifying appropriate tolerances that meet functional needs without being unnecessarily tight. 5) Creating modular assemblies for flexibility and easier maintenance.

3. How do you approach designing for manufacturability and assembly?

A successful approach to DFM and DFA (DFMA) involves a holistic view. Start by simplifying the overall product to reduce the number of parts that need to be both made and assembled. Design parts for ease of fabrication and within known process capabilities. Simultaneously, design for efficient joining methods (like snap-fits), minimize the reorientation of parts during assembly, and use features that mistake-proof the assembly process.

4. How to create a design for a manufacturer?

To create a design for a manufacturer, begin with clear and detailed communication. Provide comprehensive 3D CAD models and 2D drawings that include all necessary dimensions, tolerances (preferably using GD&T), material specifications, and required surface finishes. It's essential to collaborate with the manufacturer early to understand their specific capabilities and limitations, allowing you to tailor your design to their processes for optimal results.

-

Posted in

design for manufacturability, DFM, engineering design, manufacturing process, product development