Solving the Top Challenges in CNC Machining for Better Parts

TL;DR

The most significant challenges in CNC machining stem from tool-related failures, programming errors, material inconsistencies, and inadequate machine maintenance. These issues directly lead to poor quality finishes, increased operational costs, and costly production downtime. Overcoming these hurdles requires a combination of skilled operators, proactive maintenance schedules, and optimized programming and setup procedures.

Understanding Tool-Related Failures: Wear, Breakage, and Chatter

The cutting tool is where the machine meets the material, making it a primary point of failure. Challenges in this area typically fall into three categories: tool wear, tool breakage, and chatter. Each of these can severely compromise the quality of the final part, leading to dimensional inaccuracies and poor surface finishes. Understanding the root causes is the first step toward prevention and is critical for maintaining efficiency and quality in any machining operation.

Tool wear is the gradual degradation of the cutting edge through regular use. This is an expected part of the process, but accelerated wear can be a sign of deeper issues. It's often caused by incorrect speeds and feeds, insufficient coolant, or using a tool material that is not suitable for the workpiece. Sudden tool breakage, on the other hand, is a catastrophic failure that can damage both the workpiece and the machine itself. This is often the result of excessive force, an improper toolpath, or a flaw in the tool's manufacturing.

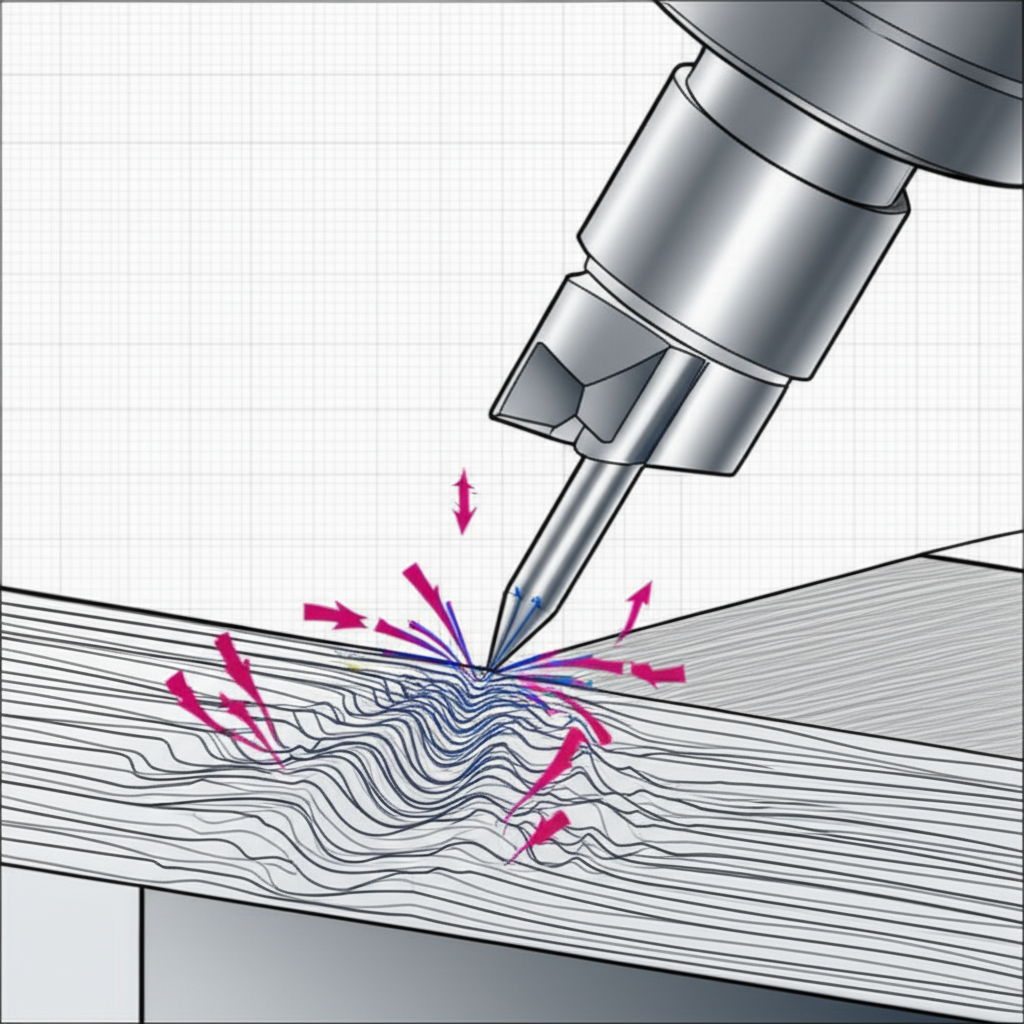

Tool chatter is a harmful vibration that occurs during the cutting process, creating a distinctive wavy or rippled pattern on the surface of the part. According to experts, this vibration reduces the tool's lifespan and can be caused by a number of factors, including a lack of rigidity in the machine or workpiece setup, an overly long tool, or incorrect cutting parameters. As noted in a detailed guide by Setco, identifying the source of chatter is key to resolving it and ensuring a smooth, accurate cut.

To mitigate these tool-related challenges, operators can implement several key strategies:

- Optimize Speeds and Feeds: Ensure that cutting speeds, feed rates, and depth of cut are perfectly matched to the specific material and tool being used.

- Ensure Proper Cooling: Use an adequate and consistent flow of coolant to reduce thermal stress on the tool and workpiece, preventing overheating and premature wear.

- Select the Right Tool: Choose high-quality tools made from materials (like carbide or diamond-coated carbide) best suited for the workpiece material's hardness and properties.

- Maintain Machine Rigidity: Regularly check and ensure that the machine, tool holders, and workpiece clamping are as rigid as possible to absorb cutting forces and prevent vibration.

Navigating Material and Workpiece Inconsistencies

The quality and consistency of the raw material, as well as how it's secured, are foundational to successful CNC machining. Even with a perfect program and a pristine machine, variations in material composition or an insecure workpiece setup can lead to defects, tool damage, and failed parts. These challenges require careful planning before the first cut is ever made.

Material inconsistencies can be a major headache. A single batch of metal or plastic might have variations in hardness, internal stresses, or composition that cause the tool to react unpredictably. This can lead to unexpected tool wear, poor surface finishes, or even part warping. Machining difficult materials, such as titanium or hardened steel, presents its own set of challenges due to their high strength and poor thermal conductivity, which can rapidly wear down cutting tools. Conversely, soft plastics can melt or deform if not machined with care and specialized tooling.

Equally important is workholding—the method used to clamp the workpiece to the machine. As highlighted by industry professionals, improper clamping is a common but critical error. An insecurely held part can shift or vibrate during machining, resulting in misalignment, chatter, and inaccurate dimensions. Over-tightening the clamps can also be problematic, as it can distort or damage the workpiece, especially with thin-walled or delicate parts. The goal is to achieve maximum rigidity without introducing stress into the component.

Here is a brief comparison of the challenges associated with two very different materials:

| Factor | Aluminum (6061) | Hardened Steel (A2) |

|---|---|---|

| Machinability | Excellent; soft and machines quickly. | Poor; high hardness requires slow speeds and specialized tools. |

| Tool Wear | Low, but can stick to cutting tools (built-up edge). | Very high; generates significant heat and abrasion. |

| Heat Management | Good thermal conductivity; dissipates heat well. | Poor thermal conductivity; heat concentrates at the cutting edge. |

| Workholding | Relatively simple, but can be marred by excessive clamping force. | Requires extremely rigid clamping to withstand high cutting forces. |

Overcoming Programming Errors and Human Factors

While CNC machines are automated, they are only as good as the instructions they receive and the operators who run them. Programming errors and other human factors are among the most common and costly challenges in CNC machining. A single misplaced decimal point or incorrect code can lead to a machine crash, scrapped parts, or damaged tooling, making this a critical area for quality control and continuous improvement.

Programming mistakes can range from simple typos to complex logical flaws in the toolpath. These errors often occur when creating the G-code that directs the machine's movements. Modern CAD/CAM software helps automate this process, but the potential for error still exists, especially if the programmer is inexperienced or the part geometry is complex. The consequences can be severe, leading to wasted materials, production delays, and significant financial loss.

To prevent these issues, running simulations is an indispensable step. Advanced software allows programmers to run a virtual machining process on a computer before sending the code to the physical machine. This helps identify potential collisions, incorrect toolpaths, and other programming flaws in a risk-free environment. Investing in robust simulation software and thorough training for programmers can provide a massive return by preventing expensive real-world failures. Furthermore, a culture of double-checking and peer review for complex programs can add another layer of protection.

Here are some common programming and operator mistakes to avoid:

- Incorrect Tool Offsets: Failing to correctly input the length and diameter of a tool can cause it to cut too deep, not deep enough, or in the wrong position.

- Wrong Coordinates or Work Offsets: Setting an incorrect starting point (zero point) for the machining operation will cause the entire part to be machined out of position.

- Syntax Errors in G-Code: Simple mistakes in the code, like using the wrong G-code or M-code, can cause the machine to behave unpredictably.

- Improper Tool Selection: An operator choosing a tool that doesn't match what was specified in the program can lead to poor quality or tool failure.

- Ignoring Machine Alarms: Not responding to machine warnings or alarms promptly can turn a minor issue into a major breakdown.

Addressing Machine Maintenance and Environmental Issues

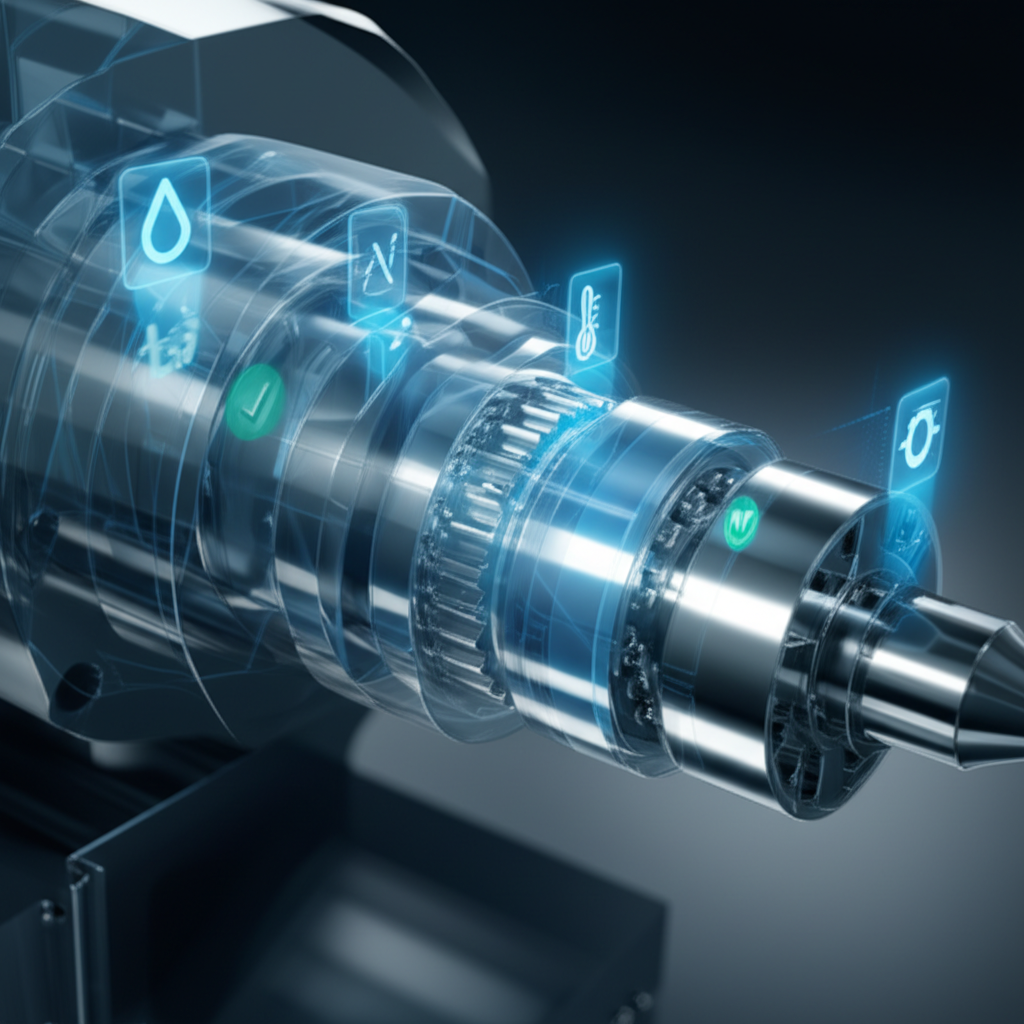

A CNC machine is a complex system of mechanical and electronic components that must work in perfect harmony to achieve precision. Neglecting regular maintenance is a surefire way to invite problems that can halt production entirely. Issues like overheating, spindle failure, and general mechanical wear are often the result of a reactive, rather than proactive, approach to machine care. These problems not only affect part quality but also shorten the lifespan of a very expensive piece of equipment.

Overheating is a frequent problem, especially during long production runs. It can be caused by a buildup of chips, inadequate coolant flow, or even high ambient temperatures in the workshop. When a machine overheats, thermal expansion can cause its components to shift slightly, leading to a loss of accuracy. In severe cases, it can damage sensitive electronics or cause the main spindle to seize. Ensuring the machine is clean, coolant systems are functioning properly, and the surrounding environment is temperature-controlled are key preventative measures.

The spindle is the heart of a CNC machine, and its health is paramount. Spindle failure is one of the most serious mechanical issues, often caused by bearing wear, contamination, or damage from a crash. Unusual noises, excessive vibration, or a poor surface finish on parts are all warning signs of a failing spindle. A comprehensive preventive maintenance program, including regular lubrication, cleaning, and vibration analysis, can help detect these issues early. As detailed by manufacturing experts, this proactive approach is far more cost-effective than waiting for a complete failure that requires a costly rebuild or replacement.

Environmental factors also play a significant role. Fluctuations in power supply can damage sensitive electronics, while excessive humidity can lead to corrosion. Dust and airborne contaminants can clog filters and foul cooling systems. A clean, stable, and well-organized workshop is not just about aesthetics; it is a critical component of a reliable and efficient CNC machining operation. Regular calibration and inspection by trained technicians will ensure the machine maintains its accuracy and reliability over time.

Scaling Production: Challenges in High-Volume CNC Machining

Transitioning from prototyping and small-batch jobs to high-volume production introduces a unique set of challenges. While CNC machining offers incredible precision and repeatability, maintaining those standards across thousands of parts requires strategic planning and robust processes. The primary hurdles in scaling up involve achieving economies of scale, ensuring consistent quality control, and optimizing production speed without sacrificing accuracy.

One of the biggest tasks is maintaining quality and consistency from the first part to the ten-thousandth. As MakerVerse explains, this requires moving from simple spot-checks to a continuous, integrated quality control system. This can involve automated in-process measurements, statistical process control (SPC) to monitor for deviations, and rigorous post-production inspections. Any variation in material, tool wear, or machine calibration can create defects that are magnified across a large production run, making a proactive quality assurance strategy essential.

Another key challenge is optimizing production speed to meet demand. In high-volume scenarios, every second of cycle time counts. This involves more than just increasing feed rates; it requires optimizing toolpaths to eliminate wasted motion, leveraging multi-axis machines to complete parts in a single setup, and implementing automation like bar feeders or robotic loaders to minimize machine downtime. Minimizing setup times between jobs through techniques like modular fixturing is also crucial for keeping the machines running and productive.

For businesses looking to scale their manufacturing, partnering with a specialized service provider can be a strategic advantage. Companies that deliver rapid prototyping and high-volume production can handle the complexities of scaling. For instance, services like XTJ CNC Machining Services offer access to advanced 4 and 5-axis machines and expertise in over 30 materials, ensuring that parts meet demanding specifications with tight tolerances. This allows businesses to achieve scalability without the massive upfront investment in equipment and expertise.

Frequently Asked Questions About CNC Machining Challenges

1. What are the common problems in CNC?

The most common problems in CNC machining include issues with the cutting tool (wear, breakage, and chatter), programming errors (incorrect G-code, wrong tool offsets), improper workpiece setup (poor clamping), inadequate machine maintenance (overheating, spindle wear), and material inconsistencies. These challenges can lead to poor part quality, increased costs, and production delays.

2. What is a major limitation of CNC machines?

A major limitation of CNC machines is the high initial cost of the equipment and software, which can be a significant barrier for smaller businesses. Another key constraint, as highlighted by American Micro Inc., is the physical size limitation; the machine's work envelope and axis travel restrict the maximum size of the part that can be produced. While highly automated, they also still require skilled programmers and operators to function effectively, and human error remains a potential factor.

3. What is the hardest material to CNC?

Generally, materials that combine high hardness, high strength, and poor thermal conductivity are the most difficult to machine. Superalloys like Inconel are often cited as the most challenging due to their tendency to work-harden rapidly and generate extreme heat during cutting, which causes rapid tool wear. Other difficult materials include titanium alloys, hardened tool steels, and advanced ceramics, all of which require specialized tools, rigid machines, and carefully optimized cutting strategies.