Practical Strategies to Reduce CNC Machining Costs

TL;DR

To effectively reduce CNC machining costs, focus on three primary areas: design for manufacturability (DFM), strategic material selection, and operational efficiency. This involves simplifying your part's geometry, such as adding generous radii to internal corners and avoiding unnecessarily deep pockets. Choosing cost-effective, highly machinable materials and specifying tolerances only where critical can also lead to significant savings by minimizing machine time and complexity.

Optimizing Part Design for Manufacturability (DFM)

The most significant impact on CNC machining costs comes directly from the design of the part itself. By adhering to Design for Manufacturability (DFM) principles, engineers and designers can dramatically cut down on machine time, tool wear, and the need for complex setups. Every design choice, from the shape of a corner to the thickness of a wall, translates directly into time and money on the machine shop floor.

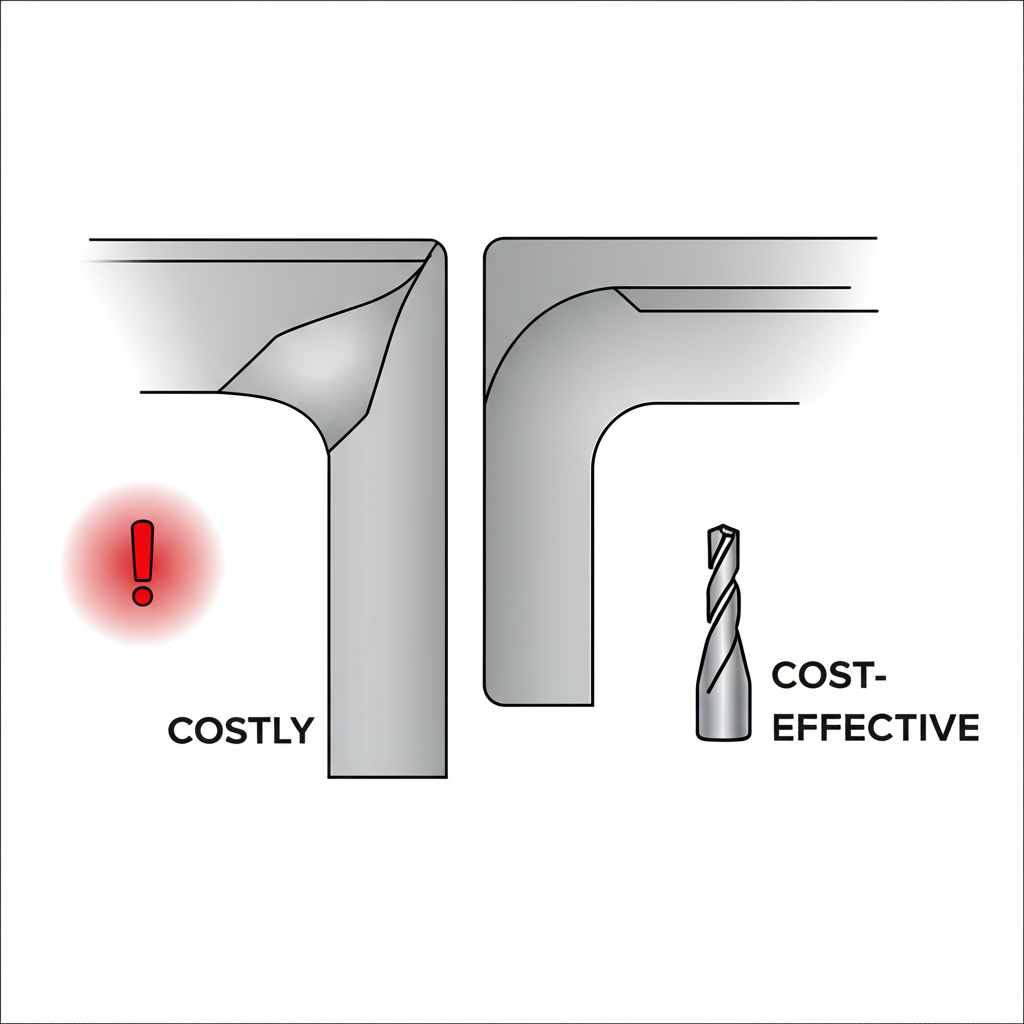

Add Generous Radii to Internal Corners

A fundamental rule in CNC milling is that cutting tools are round, and therefore, they create rounded internal corners. Attempting to machine sharp, 90-degree internal corners is impossible without specialized processes like EDM, which are expensive. To create a corner with a small radius, a smaller diameter tool is required. These smaller tools are more fragile, must cut at slower speeds, and can only remove a small amount of material per pass, all of which significantly increases machining time.

For a more cost-effective approach, design internal corners with the largest possible radius. A good rule of thumb is to make the radius at least one-third of the cavity's depth. For example, a 12 mm deep pocket should have a corner radius of at least 4 mm, allowing a larger, more robust 8 mm tool to be used efficiently. Using the same radius for all internal corners is also beneficial as it eliminates the need for tool changes.

Avoid Deep Pockets and Thin Walls

Deep pockets and thin walls present major challenges for CNC machining. Machining deep cavities is time-consuming because it requires the removal of large volumes of material, and standard cutting tools have a limited cutting length. As a general guideline, the depth of a pocket should not exceed four times its length or the tool's diameter. Going deeper requires special, longer tools that are prone to vibration and breakage, necessitating slower speeds and more careful machining.

Similarly, parts with very thin walls are difficult to machine accurately. They are prone to vibration (or "chatter") and can distort under the pressure of the cutting tool, making it hard to hold tight tolerances. For metal parts, it is recommended to design walls thicker than 0.8 mm, while for plastics, a minimum thickness of 1.5 mm is safer. If your design requires features that are inherently thin, consider if another manufacturing method, like sheet metal fabrication, might be more economical.

Standardize Holes and Threads

Using standard sizes for holes and threads is a simple yet powerful way to reduce costs. Standard-sized holes can be created quickly with common drill bits. If a non-standard size is specified, it requires an additional step using an end mill to bore the hole to the exact dimension, adding time and cost. Likewise, thread length should be limited. A thread's holding power doesn't increase significantly beyond 1.5 times the hole's diameter, so specifying a thread depth of more than three times the diameter only increases the risk of tool breakage and adds unnecessary machine time.

Strategic Material Selection

The material you choose for your part influences not only its physical properties but also the total manufacturing cost. The price of the raw material is one factor, but its machinability—the ease with which it can be cut—is often more critical. Harder, more abrasive materials require slower cutting speeds, cause more tool wear, and ultimately increase the time your part spends on the machine.

Softer materials are generally less expensive to machine. For instance, aluminum alloys like 6061 are highly machinable and relatively inexpensive, making them an excellent choice for many applications. In contrast, stainless steel is much harder and can take more than twice as long to machine as aluminum. Even within material families, there are differences; 303 stainless steel is formulated for better machinability than the more common 304 grade. When performance requirements allow, always opt for the material with the best machinability. Consulting with an experienced service provider can be invaluable; for example, services like XTJ work with over 30 materials and can help identify the most cost-effective option for your specific needs, ensuring components meet demanding specifications with optimized material choices.

The following table provides a brief comparison of common materials:

| Material | Relative Cost | Machinability | Common Applications |

|---|---|---|---|

| Aluminum 6061 | Low | Excellent | Prototypes, structural components, electronic housings |

| Mild Steel (e.g., 1018) | Low | Good | General purpose parts, fixtures, mounting plates |

| Stainless Steel 304 | Medium | Fair | Food grade equipment, corrosion-resistant parts |

| POM (Delrin/Acetal) | Low | Excellent | Bushings, gears, high-stiffness plastic parts |

| PEEK | Very High | Fair | High-performance aerospace and medical components |

The Critical Role of Tolerances and Surface Finishes

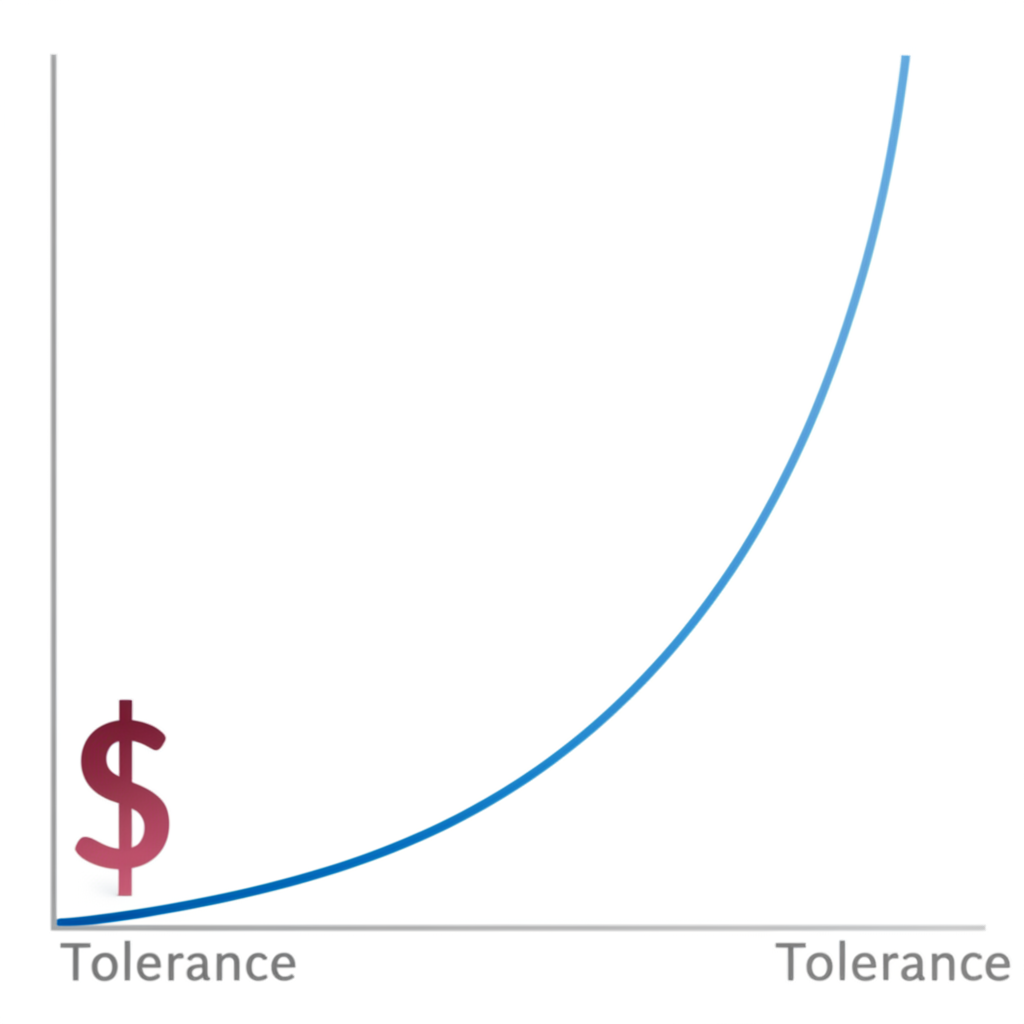

Specifying tolerances and surface finishes that are tighter or finer than necessary is one of the most common drivers of excessive CNC machining costs. Each level of increased precision often requires additional machining passes, slower cutting speeds, more frequent inspections, and sometimes even secondary processes like grinding. This relationship is not linear; the cost often increases exponentially as tolerances become tighter.

A standard machining tolerance, such as ±0.125 mm (or ±0.005"), is sufficient for most non-critical features and is achieved without special effort. Tighter tolerances should be applied selectively and only to the surfaces where they are functionally essential, such as mating faces or bearing bores. Clearly defining a single datum on your technical drawing and dimensioning all critical features from that point can also help the machinist achieve accuracy more efficiently.

Key takeaway: Apply tight tolerances and fine surface finishes only where they are absolutely critical for the part's function. For all other surfaces, accept the standard as-machined finish and tolerance to avoid unnecessary expense.

Similarly, the standard "as-machined" surface finish is the most cost-effective option. Requesting smoother finishes requires extra processing steps. Specifying multiple different finishes on a single part is even more expensive, as it involves masking and additional handling. Unless aesthetics or specific surface properties are paramount, sticking with a single, standard finish is the most economical choice.

Streamlining Machine Setups and Operational Efficiency

Beyond design and materials, operational factors play a crucial role in the final cost of a machined part. Two key elements to consider are the number of machine setups and the production volume. Each time a part has to be unclamped, rotated, and re-fixtured to machine features on a different side, it incurs a new "setup" cost. This is often a manual process that adds significant labor time and introduces potential for error.

To minimize these costs, design parts that can be machined in a single setup whenever possible. This means consolidating features onto as few faces as you can. If a part has complex geometry with features on all six sides, it may be more economical to split it into multiple, simpler components that can each be machined in one or two setups and then assembled with fasteners. This approach simplifies fixturing and reduces manual intervention.

Finally, leverage economies of scale. The initial costs for CAM programming and machine setup are fixed, whether you are making one part or one hundred. When you order a larger quantity, these one-time costs are spread across more units, dramatically lowering the price per part. Ordering five parts instead of one can often cut the unit cost by half or more. For this reason, CNC machining becomes increasingly cost-effective as you move from single prototypes into low-to-medium volume production runs.

Key Takeaways for Cost-Effective Machining

Reducing CNC machining costs is an achievable goal that hinges on thoughtful planning and smart design. By prioritizing manufacturability from the outset, you can avoid common pitfalls that inflate expenses. The most impactful strategies involve simplifying part geometry, such as using large corner radii and avoiding thin walls, which directly reduces complex and time-consuming machine operations.

Furthermore, making informed decisions about materials and tolerances provides another layer of control over the budget. Choosing a material with high machinability can be more important than raw material cost, and applying tight tolerances only to critical features prevents paying for precision you don't need. By combining these design principles with operational efficiencies like minimizing setups and ordering in strategic quantities, you can achieve high-quality parts that meet both functional requirements and financial targets.

Frequently Asked Questions

1. How can I reduce my CNC machining costs?

You can significantly reduce CNC machining costs by focusing on several key areas:

- Optimize Part Design: Simplify the geometry, add radii to all internal corners, avoid deep pockets and thin walls, and use standard hole and thread sizes.

- Select Materials Wisely: Choose materials with good machinability, like Aluminum 6061 or POM (Delrin), whenever your design requirements allow.

- Loosen Tolerances: Only specify tight tolerances and fine surface finishes on critical features. Standard tolerances are sufficient for most surfaces.

- Minimize Setups: Design parts so they can be machined from the fewest possible directions, ideally in a single setup.

- Increase Order Quantity: Leverage economies of scale by ordering parts in larger batches to reduce the per-unit cost.

2. How much does CNC machining cost per hour?

The hourly rate for CNC machining can vary widely, typically ranging from $35 to $200 per hour. This cost is influenced by the type and sophistication of the machine (e.g., 3-axis vs. 5-axis), the complexity of the part, and the material being machined. Harder materials and more complex geometries require more time and more advanced machinery, thus increasing the hourly cost.

3. Does a higher quantity reduce CNC machining costs?

Yes, absolutely. CNC machining has initial setup costs for programming and fixturing that are the same whether you make one part or a hundred. When you order a higher quantity, these fixed costs are distributed across all the parts, which significantly lowers the cost per unit. This effect is known as economies of scale and is one of the most effective ways to reduce costs for production runs.