Multi-Axis Machining: How It Works and Its Key Benefits

TL;DR

Multi-axis machining is an advanced manufacturing process where a cutting tool moves along four or more axes to create complex parts from materials like metal or plastic. By adding rotational movements to the standard three linear axes (X, Y, Z), these machines can produce intricate geometries with greater precision, better surface finishes, and in fewer steps than traditional methods. This capability significantly reduces production time and the potential for human error.

Understanding the Fundamentals: What Is Multi-Axis Machining?

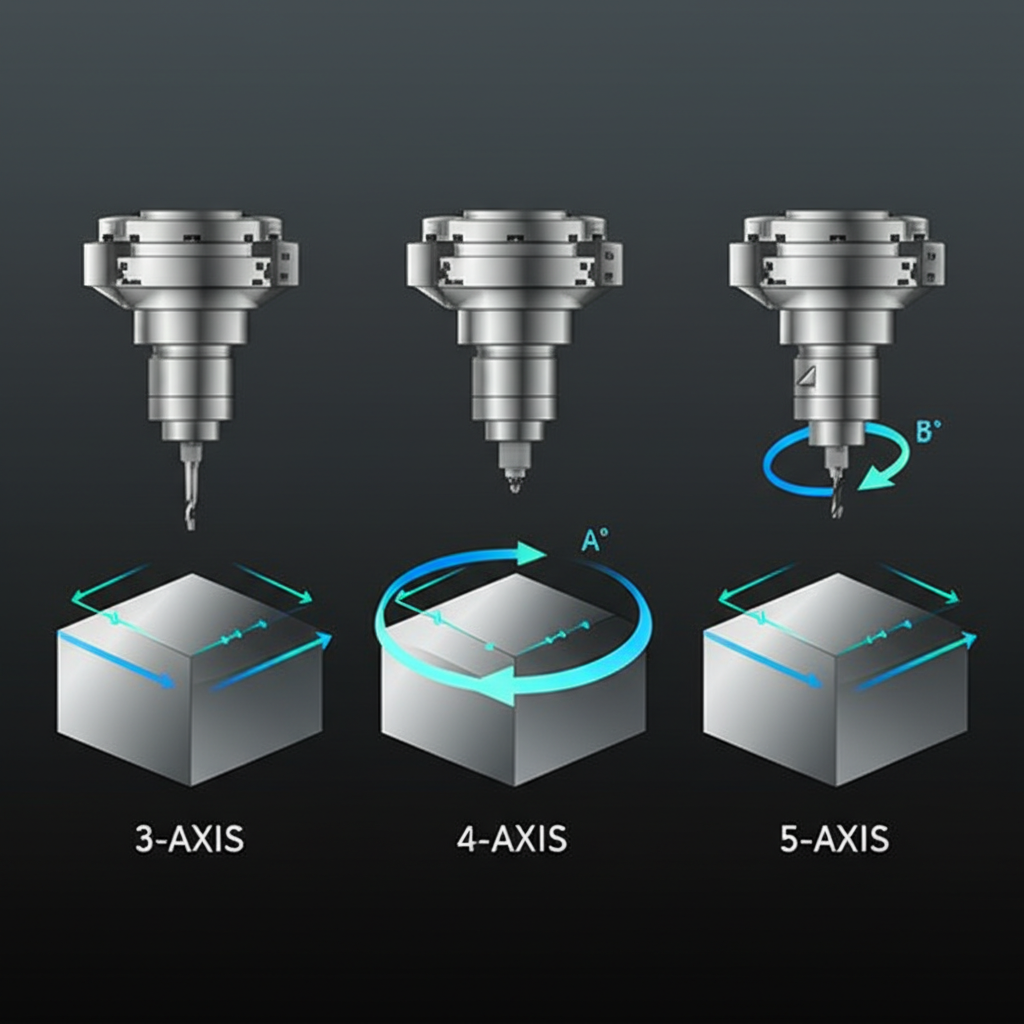

Multi-axis machining represents a significant evolution from conventional manufacturing techniques. At its core, it is a computer numerically controlled (CNC) process that expands a machine's range of motion beyond the three simple linear axes. In traditional 3-axis machining, the cutting tool can move left-to-right (X-axis), back-and-forth (Y-axis), and up-and-down (Z-axis). While effective for simpler parts, this method requires the workpiece to be manually reoriented to machine different faces, introducing potential inaccuracies with each new setup.

Multi-axis machining overcomes this limitation by incorporating rotational axes. A 4-axis machine adds one rotational axis (typically the A-axis, which rotates around the X-axis), allowing the tool to approach the workpiece from more angles. A 5-axis machine, the most common configuration, adds two rotational axes (which can be a combination of the A, B, and C axes), enabling the tool to access the workpiece from virtually any direction in a single setup. As detailed by manufacturing experts at Mastercam, this ability to move in four or more directions simultaneously is what defines the process and allows for the creation of highly complex components.

The concept of 'degrees of freedom' is central to understanding this technology. Each axis represents a degree of freedom. By increasing these degrees, the machine can maintain an optimal cutting position and angle relative to the material's surface at all times. This not only allows for the carving of complex curves and contours but also improves the overall quality and efficiency of the manufacturing process, a point emphasized in educational resources like Wikipedia's overview on the topic.

The Key Differentiator: How Multi-Axis Machining Works

The operational advantage of multi-axis machining lies in its ability to complete complex jobs in a single setup. In a traditional 3-axis process, machining a part with features on multiple sides requires stopping the machine, removing the workpiece, placing it in a new fixture at a different orientation, and recalibrating the machine. This process is time-consuming and introduces a risk of error with every manual adjustment.

Multi-axis machines eliminate most, if not all, of these intermediate steps. By rotating either the tool head or the table holding the workpiece (or both), the machine can present different faces of the part to the cutting tool without manual intervention. This continuous process allows for a fluid, uninterrupted toolpath that moves tangentially across the part's surface. The result is a smoother surface finish, as there are no blend marks or imperfections that can arise from separate setups.

This single-setup approach, often called 'done-in-one' machining, provides several key operational advantages:

- Reduced Lead Times: By eliminating the need for multiple setups, the total time to produce a finished part is drastically shortened.

- Increased Accuracy: Each time a part is moved manually, there's a chance for small alignment errors. Keeping the part in one position for all operations ensures higher dimensional accuracy and consistency between parts.

- Shorter Cutting Tools: Because the tool head or table can tilt to reach difficult areas, shorter, more rigid cutting tools can be used. These shorter tools are less prone to vibration, which further improves accuracy and surface finish while also extending the tool's lifespan.

The entire process is driven by Computer-Aided Manufacturing (CAM) software, which translates a 3D digital model of the part into a set of precise instructions, or G-code, that the CNC controller executes. This high level of automation ensures that even the most complex toolpaths are performed with perfect repeatability.

Exploring the Configurations: Types of Multi-Axis Machines

While the term 'multi-axis' covers any machine with four or more axes, the capabilities and applications can vary significantly between configurations. The most common types are 4-axis and 5-axis machines, with the latter having an important distinction between positional and simultaneous operation.

4-Axis Machining: This configuration adds a single rotational axis (the A-axis) to the three linear axes. Typically, the workpiece is mounted on a rotary table that can spin around the X-axis. This is ideal for machining features on the sides of a cylindrical part, such as drilling holes or cutting slots, without needing to re-clamp it. It's a cost-effective step up from 3-axis for parts with moderate complexity.

5-Axis Machining: This is the most versatile and widely discussed form of multi-axis machining. It adds two rotational axes, allowing for full 3D machining of complex shapes. However, there are two primary modes of 5-axis operation:

- 3+2 Axis Machining (Positional): In this mode, the machine uses its two rotational axes to orient the workpiece into a fixed, tilted position. Once locked in place, the machine performs a standard 3-axis cutting operation. It then reorients the part to another angle and repeats the process. As explained by industry resource 3ERP, this is not true simultaneous movement, but it allows a 3-axis program to machine five sides of a part in a single setup, which is a massive efficiency gain.

- Simultaneous 5-Axis Machining: This is the most advanced configuration, where all five axes—three linear and two rotational—move at the same time in a coordinated, continuous motion. This allows the machine to create complex contoured surfaces, undercuts, and organic shapes found in aerospace components, medical implants, and intricate molds.

The table below summarizes the key differences between these common configurations:

| Configuration | Axes of Motion | Key Capability | Common Applications |

|---|---|---|---|

| 3-Axis | X, Y, Z (Linear) | Machining one side at a time | Simple prismatic parts, drilling, facing |

| 4-Axis | X, Y, Z + A (Rotation around X) | Machining around a cylindrical part | Cams, engravings on curved surfaces |

| 3+2 Axis | X, Y, Z + two rotational axes (e.g., A, B) (Positional) | Machining five sides in one setup | Housings, brackets, parts with angled holes |

| Simultaneous 5-Axis | X, Y, Z + two rotational axes (e.g., A, B) (Continuous) | Full 3D contouring and complex surfaces | Turbine blades, medical implants, molds |

Beyond 5-axis, machines with 6, 9, or even 12 axes exist for highly specialized applications, often combining milling and turning operations into a single hybrid machine for ultimate efficiency.

The Strategic Advantages: Key Benefits of Multi-Axis Machining

Adopting multi-axis machining technology provides significant strategic advantages that translate directly to higher quality products and a more efficient manufacturing process. The benefits extend beyond simply making complex parts, impacting cost, speed, and precision across the board.

-

Manufacturing of Complex Geometries

This is the most celebrated benefit. Multi-axis machines can produce parts with intricate curves, undercuts, and angled features that are impossible or impractical to create with 3-axis machines. This capability is essential for industries like aerospace, which relies on complex components like turbine blades and impellers, and the medical field for creating custom-fit implants and prosthetics, as noted by RapidDirect.

-

Improved Accuracy and Surface Finish

By completing a part in a single setup, the cumulative error from repositioning the workpiece is eliminated, leading to much tighter tolerances and higher overall accuracy. Furthermore, the tool can be programmed to maintain a tangential orientation to the part's surface, resulting in a superior, machine-finished surface that often requires no secondary polishing or hand-finishing.

-

Reduced Setup and Lead Times

The 'done-in-one' approach drastically cuts down on total production time. It eliminates the labor-intensive process of creating multiple fixtures and manually re-clamping the part for each operation. This efficiency gain shortens lead times, allowing for faster turnaround on both prototypes and full production runs. For projects with tight deadlines, services that leverage this technology are invaluable. For example, some providers offer advanced 4 and 5-axis CNC machining to deliver high-precision custom parts with lead times as short as a few days, handling everything from rapid prototyping to volume production.

-

Enhanced Tool Life and Efficiency

The ability to tilt the tool or workpiece allows for the use of shorter, more rigid cutting tools. These tools are less susceptible to vibration and deflection, which means they can cut more aggressively and last longer. This reduces tooling costs and minimizes the downtime required for tool changes, further optimizing the manufacturing process.

Frequently Asked Questions

1. What is the main difference between 3-axis and 5-axis machining?

The primary difference is the number of directions the cutting tool can move. A 3-axis machine operates on three linear axes (X, Y, and Z), making it suitable for simpler, prismatic parts. A 5-axis machine adds two rotational axes, allowing the tool to approach a workpiece from all directions. This enables the creation of highly complex shapes and contours in a single setup, which drastically improves efficiency and accuracy.

2. Is 3+2 axis machining the same as simultaneous 5-axis?

No, they are different. In 3+2 axis (or positional) machining, the two rotational axes are used to lock the workpiece into a tilted position, after which a standard 3-axis cutting operation is performed. In simultaneous 5-axis machining, all five axes move at the same time in a continuous, coordinated motion to follow complex toolpaths. While 3+2 is more efficient than standard 3-axis, simultaneous 5-axis is required for true 3D contouring.

3. What industries benefit most from multi-axis machining?

Industries that require parts with high complexity and precision are the primary beneficiaries. This includes aerospace (for engine components, turbine blades), medical (for custom implants, surgical tools), automotive (for engine blocks, molds), and defense. However, its efficiency benefits are making it increasingly common in general manufacturing for any part that requires machining on multiple faces.

-

Posted in

5-axis machining, cnc machining, Manufacturing Technology, multi-axis machining, precision engineering