Stainless Steel SS 316 Vs 304, 316L, 316H: Choose With Confidence

What Sets Stainless Steel SS 316 Apart?

What is stainless steel SS 316?

When you’re searching for a material that can stand up to corrosive environments, “stainless steel ss 316” is a term you’ll see everywhere. But what exactly is it? SS 316, also known as AISI 316, UNS S31600, or simply “type 316 stainless steel,” is an austenitic stainless steel alloy. That means it’s part of the same family as the popular 304 grade, but with one crucial upgrade: the addition of molybdenum. This small change makes a big difference, especially in environments where chlorides (like salt water) or harsh chemicals are present.

Why 316 stainless steel is called marine grade

Ever wondered why 316 stainless steel is so often called “marine grade stainless steel”? The answer lies in its superior resistance to pitting and crevice corrosion—two forms of localized attack that can quickly ruin lesser alloys in salty or chemically aggressive environments. Thanks to its molybdenum content (typically 2–3%), 316 stainless offers a significant bump in protection compared to 304, which lacks this element. That’s why you’ll find it used in boat fittings, dock hardware, and even coastal architectural features where salt spray is a constant threat (source).

When to choose 316 over general-purpose stainless steels

Sounds complex? Imagine you’re designing equipment for a food processing plant, a chemical storage tank, or even medical implants. In these cases, you need more than just basic corrosion resistance—you need a material that can handle acids, alkalis, and chlorides without breaking down. That’s when ss 316 shines. While 304 stainless is a good all-around choice for less demanding environments, 316 is the go-to for applications where failure isn’t an option.

- Superior resistance to chlorides and harsh chemicals (thanks to molybdenum)

- Retains toughness and formability (easy to fabricate, weld, and shape)

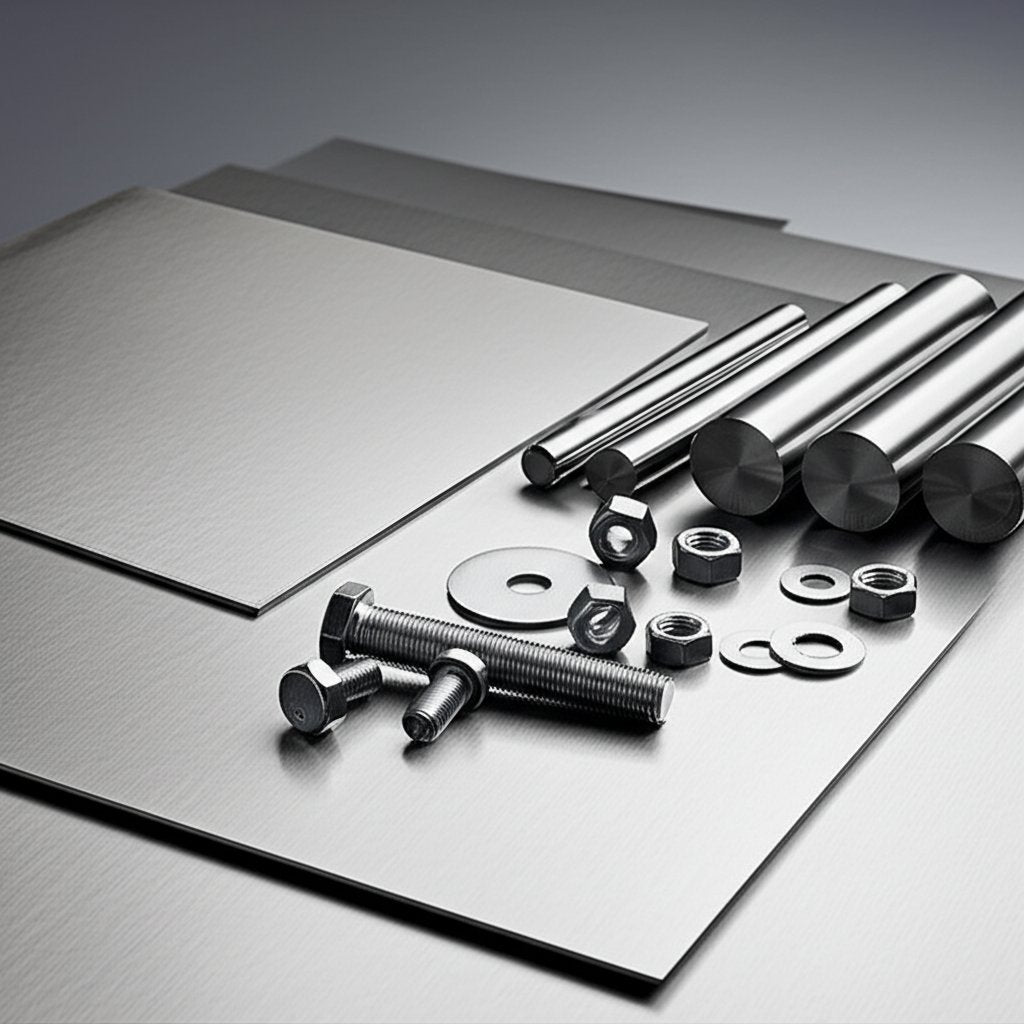

- Available in diverse product forms (sheet, plate, bar, tube, fasteners)

- Common finishing options (2B, BA, and brushed finishes for functional and aesthetic needs)

- Not immune to all corrosion (still susceptible to crevice corrosion and “tea staining” in some marine settings)

316 offers reliable chloride resistance but is not immune to crevice corrosion—always consider the specific service environment.

Typical uses for 316 stainless steel extend beyond marine hardware. You’ll find it in:

- Food and beverage processing equipment (resistant to acids and cleaning agents)

- Pharmaceutical and medical devices (non-reactive and easy to sterilize)

- Chemical processing plants (withstands aggressive chemicals and solvents)

- Architectural features in coastal environments (resists salt spray and atmospheric corrosion)

It’s important to note that the performance of ss 316 is highly dependent on the environment. While it’s a top performer in many scenarios, no stainless steel is completely “rust-proof.” Later sections will provide tables and data to help you match the right grade to your application.

So, whether you call it 316 stainless, SS 316, AISI 316, or type 316 stainless steel, you’re looking at a material trusted for its balance of strength, formability, and superior corrosion resistance—especially when chloride exposure is part of the equation.

What Makes 316 Stainless Steel Unique?

What 316 Means in Material Designation

When you see “316” in the context of stainless steel, you’re looking at a specific recipe within the austenitic family. But what’s actually in that recipe? And how do small changes in chemistry make a big difference in performance? Let’s break down the 316 stainless steel composition and see why it matters.

| Element | Typical Range (% by weight) | Function in Alloy |

|---|---|---|

| Carbon (C) | 0.00–0.07 (316) 0.00–0.03 (316L) 0.04–0.08 (316H) |

Controls grain boundary carbide precipitation and strength; lower carbon (as in aisi 316l) improves weldability |

| Chromium (Cr) | 16.50–18.50 | Provides general corrosion resistance and forms the passive layer |

| Nickel (Ni) | 10.00–13.00 | Stabilizes austenite for ductility and toughness |

| Molybdenum (Mo) | 2.00–3.00 | Boosts resistance to pitting and crevice corrosion, especially in chlorides |

| Manganese (Mn) | 0.00–2.00 | Improves hot workability and deoxidizes during steelmaking |

| Silicon (Si) | 0.00–1.00 | Enhances oxidation resistance and deoxidizes |

| Phosphorus (P) | 0.00–0.05 | Kept low to avoid embrittlement |

| Sulfur (S) | 0.00–0.02 | Kept low for ductility; higher in free-machining variants |

| Nitrogen (N) | Up to 0.10 | Strengthens the austenitic structure, especially in 316LN |

How Molybdenum Boosts Pitting Resistance

Ever wondered why 316 outperforms 304 in chemical plants or saltwater docks? The answer is molybdenum. This element, present at 2–2.5%, is the secret behind 316’s superior resistance to localized attack from chlorides. If you’re specifying for splash zones, food processing lines, or even medical equipment, that extra molybdenum is a game-changer.

Why Low Carbon Matters in 316L

Here’s where things get even more interesting. The “L” in 316L stands for “low carbon.” Why does this matter? When you weld stainless, high carbon content can cause chromium carbides to form at grain boundaries, making the steel vulnerable to intergranular corrosion. Aisi 316l, with its maximum 0.03% carbon, virtually eliminates this risk. That’s why 316L is the default choice for thick welded assemblies or where post-weld annealing isn’t practical.

Variants: 316H, 316Ti, and Nitrogen-Strengthened Grades

Need something for high temperatures? 316H has a higher carbon range (0.04–0.08%) to boost creep strength above 500°C. For situations where you’ll hold the material at high temperatures for extended periods, 316Ti adds a touch of titanium to stabilize the structure and prevent carbide precipitation. Nitrogen-strengthened versions (like 316LN) further increase strength for critical applications.

- Lower carbon (316L): Improves weld heat-affected zone resistance and prevents sensitization

- Higher carbon (316H): Delivers better creep and high-temperature strength

- Molybdenum: Essential for pitting and crevice corrosion resistance in chloride-rich environments

- Nitrogen: Adds strength without sacrificing ductility

To sum up, the ss316 composition is carefully balanced to deliver toughness, corrosion resistance, and formability. But even small tweaks—like the lower carbon in aisi 316l or the extra carbon in 316H—can dramatically shift the alloy’s strengths. That’s why it’s so important to match the grade to your application’s needs.

Next up, we’ll dive into the mechanical and physical properties that help you make engineering decisions with confidence.

Mechanical and Physical Properties You Can Trust

Baseline Mechanical Properties for 316

When you’re selecting a material for a demanding environment, you want to know exactly what to expect from your stainless steel ss 316. Sounds complex? Let’s break it down. Whether you’re designing for strength, ductility, or formability, the core mechanical properties of 316 stainless steel provide a solid foundation for most engineering applications. These values are typically specified for the annealed condition (the most common supply state for sheet, plate, and bar forms).

| Property | Typical Value (Sheet/Plate/Bar) | Standard/Test Method |

|---|---|---|

| Tensile Strength (Min.) | 515 MPa (75,000 psi) | ASTM A240 / ASME SA-240 |

| Yield Strength, 0.2% Proof (Min.) | 205 MPa (30,000 psi) | ASTM A240 / ASME SA-240 |

| Elongation in 2" (Min.) | 40% | ASTM A240 |

| Hardness (Max.) | 217 HB or 95 HRB | ASTM A240 |

Values are minimums for annealed plate, sheet, and strip. For bar, values may vary slightly by diameter and processing. Always confirm with your specific mill certs.

- 316 stainless steel yield strength is robust enough for most pressure-retaining and structural uses.

- High elongation means this alloy can be shaped and formed without cracking.

- Typical 316 stainless steel hardness remains moderate, making it machinable while retaining toughness.

Thermal Properties That Affect Design

Imagine you’re designing a heat exchanger or a vessel that cycles between hot and cold. You’ll want to know how 316 handles temperature swings—here’s where physical properties like density, thermal conductivity, and expansion come into play. These values are essential for stress calculations, thermal cycling, and fit-up tolerances.

| Property | Typical Value | Temperature | Reference |

|---|---|---|---|

| Density of stainless steel 316 | 8.00 g/cm³ (0.29 lb/in³) | Room Temp (20°C) | UPMET |

| Thermal conductivity of stainless steel 316 | 14.6 W/m·K | 20–100°C | UPMET |

| Coefficient of thermal expansion stainless steel 316 | 16.5 × 10-6 /K | 20–100°C | UPMET |

| Specific Heat | 450 J/kg·K | 20°C | UPMET |

| Young's modulus of 316 stainless steel | 200 GPa (29 × 106 psi) | Room Temp | UPMET |

For more detailed temperature-dependent data, see AZoM.

- Thermal conductivity of stainless steel 316 is lower than carbon steels—important for heat transfer calculations.

- Coefficient of thermal expansion stainless steel 316 means it expands more than carbon steel when heated—plan for this in multi-material assemblies.

- Young's modulus of 316 stainless steel indicates high stiffness, supporting structural stability.

How Product Form and Temperature Shift Values

You’ll notice that the numbers above are for the annealed state at room temperature. But what if your application sees higher temperatures or uses different product forms? Here are a few practical trends to keep in mind:

- At elevated temperatures (over 500°C), yield strength and modulus decrease—always use temperature-corrected values for design.

- Cold-worked bar or strip will have higher strength but less ductility than annealed sheet or plate.

- Welded zones may show slightly lower mechanical properties than the base metal, especially if not post-weld annealed.

Do not mix room-temperature and elevated-temperature values when setting allowables. Always check the relevant product standard and temperature correction factors for your design.

Understanding these 316 stainless steel properties—mechanical and thermal—helps you make confident, safe choices for your next project. Up next, we’ll show how these values stack up against 316L, 316H, and other grades for real-world selection.

Choosing Among 316, 316L, 316H, and Adjacent Grades

316 vs 316L for Welded Assemblies

When you’re deciding between 316 and 316L stainless steel for your next fabrication project, the conversation often centers on weldability and corrosion resistance. Sounds complex? Let’s simplify: the main difference is carbon content. 316L stainless steel contains a maximum of 0.03% carbon, while standard 316 maxes out at 0.08%. Why does this matter? Lower carbon in 316L means less risk of carbide precipitation during welding—so you avoid intergranular corrosion at weld joints. If your design calls for a lot of welding, especially in corrosive or marine environments, 316L is usually the safer bet and often doesn’t require post-weld annealing. Standard 316 welds well too, but may need extra heat treatment to restore full corrosion resistance.

When 316H Makes Sense at Higher Temperatures

Imagine you’re building a heat exchanger or a pressure vessel for a chemical plant—continuous high temperatures are the norm. Here, 316H stainless steel stands out. With a carbon content between 0.04% and 0.10%, 316H offers improved creep strength and stability at elevated temperatures (above 500°C/932°F). This makes it the material of choice for boilers, superheaters, and high-pressure steam piping. While 316L and standard 316 maintain good properties up to 550°C, 316H is specifically engineered to deliver better performance in long-term, high-heat applications (reference).

How 316 Compares with 304, 304L, and 317L

Ever wondered how 316 stacks up against other common stainless grades? Let’s break it down. Compared to 304 or 304L (the workhorse of stainless steels), 316 and its variants have better resistance to chlorides and pitting corrosion, thanks to their 2–3% molybdenum content. If you’re working in a salty, chemical, or coastal environment, 316-series grades are usually the smarter pick. For even harsher chloride-rich conditions, 317L or duplex stainless steels may be necessary, as they offer higher PREN (Pitting Resistance Equivalent Number) values and more robust corrosion resistance.

| Grade | PREN (Pitting Resistance) |

Weldability | Max. Service Temp (°C) | Typical Applications | Key Standards |

|---|---|---|---|---|---|

| 316 | 24–25 | Good; post-weld anneal may be needed | ~550 | Food, pharma, marine, chemical | ASTM A240, A312 |

| 316L | 24–25 | Excellent; no post-weld anneal needed | ~550 | Welded tanks, piping, medical devices | ASTM A240, A312 |

| 316H | 24–25 | Good; control heat input | ~600–870 | Boilers, heat exchangers, power gen | ASTM A240, A312 |

| 304 / 304L | 18–20 | Excellent | ~550 | General purpose, less chloride exposure | ASTM A240, A312 |

| 317L | 27–30 | Good | ~550 | Severe chloride, chemical process | ASTM A240, A312 |

PREN calculated as Cr + 3.3Mo + 16N.

- Choose 316L for heavy welding—its low carbon content prevents weld decay and intergranular corrosion.

- Consider 316H stainless steel for high-temperature, high-pressure service—its higher carbon boosts creep strength.

- Step up to 317L or duplex stainless steel if chlorides are severe—higher PREN means better pitting resistance.

- Stick with 304/304L for less aggressive environments—more cost-effective for basic corrosion needs.

Key takeaway: Match the grade to your environment and fabrication method. 316L wins for welded assemblies in corrosive settings. 316H stainless steel is the go-to for elevated temperatures. For the harshest chloride conditions, consider 317L or duplex alternatives.

Up next, we’ll show how to move from choosing a grade to selecting the right prototyping process—so you can turn your material choice into a real-world part, with the right finish and tolerances.

From Material Choice to Rapid Prototyping Execution

Process Selection for 316 Prototypes

When you’re ready to turn a design into a real part, the way you process 316 stainless steel sheet metal can make or break your project. Should you choose CNC machining, sheet forming, or casting? Each method brings its own strengths—and knowing how 316 behaves in these processes lets you make smarter decisions, especially for corrosion-critical or high-spec applications.

| Vendor/Process | Lead Time | Finish Options | Best Use Cases | 316-Specific Notes |

|---|---|---|---|---|

| XTJ Rapid Prototyping Services | Fast (as quick as days) | 2B mill finish, bead-blast, brushed, custom | Precision 316 stainless steel sheet, complex geometries, tight tolerances | Free DFM feedback, ISO 9001:2015 QC, ideal for corrosion-critical features |

| CNC Machining (in-house or other vendors) | Medium | Stainless steel mill finish, custom post-processing | Low-volume parts, intricate details, functional prototypes | 316 is tougher to machine than 304; use sharp tools and coolant |

| Sheet Metal Forming | Short to medium | 2B mill finish, #4 brushed, custom textures | Enclosures, brackets, panels using 316 ss sheet | Excellent formability, but plan for springback and higher force |

| Investment Casting | Longer | As-cast, bead-blast, limited polish | Complex 3D shapes, low to medium volumes | Good for corrosion-resistant parts, but less precise than machining |

DFM Tips to Reduce Cost and Lead Time

Design for Manufacturability (DFM) is your shortcut to faster, more cost-effective prototypes—especially with 316 stainless steel sheet. Here’s a practical workflow to get it right the first time:

- Choose the right process early. For tight tolerances or fine details, CNC machining or precision sheet forming is best. For larger, less intricate parts, consider investment casting.

- Specify the finish up front. A 2B mill finish is the standard for most 316 ss sheet, balancing cost and corrosion resistance. For more visual appeal or easier cleaning, opt for brushed or bead-blast finishes (reference).

- Optimize feature sizes and wall thickness. Keep cutouts, holes, and bends within standard tooling limits. For sheet metal, minimum bend radii and hole diameters should match material thickness to avoid cracking.

- Plan for achievable tolerances. Typical tolerances for CNC-machined 316 stainless steel sheet metal are ±0.005–0.010 in. (0.13–0.25 mm), but always confirm with your prototyping partner.

- Engage DFM experts early. Services like XTJ Rapid Prototyping offer complimentary DFM reviews, helping you catch costly errors before production.

Finishing and Inspection Checkpoints

The finish you choose for your stainless 316 plate or 316 ss sheet affects not just aesthetics, but also corrosion resistance and cleanability. Here’s how to navigate the most common options:

- 2B mill finish: Smooth, lightly reflective, and the go-to for most industrial and food-grade applications. It’s the default for many 316 stainless steel sheet products.

- Brushed (No. 4) finish: Offers a linear grain and is popular for visible surfaces on appliances or architectural panels.

- Bead-blast or custom finishes: Provide a matte texture and can reduce glare or enhance grip, but may slightly lower corrosion resistance if not properly passivated.

- Stainless steel mill finish: Refers to any finish applied at the mill, including 2B and BA (Bright Annealed). Always clarify your needs to avoid confusion with suppliers.

Inspection should confirm thickness, flatness, and finish quality. For critical parts, surface roughness (Ra) or specific grain direction may be required—especially in pharmaceutical or food contact settings.

Choosing the right finish—like 2B mill finish or brushed—can dramatically impact both performance and appearance. Always specify your requirements clearly on drawings and purchase orders.

Ready to move from material selection to prototype? Services like XTJ Rapid Prototyping can help you validate your design, optimize for 316’s unique properties, and deliver functional parts with the right finish and tolerances. If you have in-house capability, follow these DFM and finishing tips to ensure your prototypes perform as intended—especially when working with demanding 316 stainless steel sheet metal applications.

Next, we’ll explore how corrosion mechanisms impact 316 in the real world—and what you can do to troubleshoot and prevent failures before they start.

Corrosion Resistance and Real World Troubleshooting

How 316 Resists Chlorides—and Where It Can Fail

When you choose marine grade 316 stainless steel, it’s tempting to think you’re safe from corrosion in any environment. But is that true? Let’s break it down. The secret behind 316’s reputation as “marine stainless steel” is its molybdenum content, which significantly boosts its resistance to pitting and crevice corrosion in chloride-rich settings—think seawater, de-icing salts, or chemical processing plants. That’s why it’s the go-to for boat fittings, food processing, and medical devices where 316L stainless steel properties matter.

But there’s a catch: even 316 isn’t invincible. Under certain conditions—tight crevices, stagnant water, or high chloride concentrations—localized corrosion can still occur. And if you add tensile stress to the mix, stress corrosion cracking (SCC) becomes a real threat, especially around welds or cold-worked areas (BSSA). So, while 316 is a strong performer, context and maintenance are always key.

Understanding Pitting, Crevice, and Stress Corrosion Cracking

- Pitting corrosion: Localized attack forming tiny, deep holes—often triggered by chlorides. Superficial in most cases but can lead to staining or, in severe cases, through-wall leaks.

- Crevice corrosion: Occurs where oxygen is limited, such as under gaskets, washers, or deposits. The narrower and deeper the crevice, the more aggressive the attack.

- Stress corrosion cracking (SCC): Needs three ingredients: tensile stress, a susceptible material, and a corrosive environment (often chloride-rich). Cracks typically start at pits or welds and propagate along stress lines, sometimes leading to sudden failure (ScienceDirect).

Reading Corrosion Test Data and PREN

How do you know if your 316 part will hold up? Engineers often use the Pitting Resistance Equivalent Number (PREN) as a predictive tool. The higher the PREN, the better the alloy resists pitting in chloride environments. For 316, PREN values typically fall in the 24–25 range, thanks to its molybdenum content. But if your service conditions are especially harsh—think offshore platforms or chemical reactors—stepping up to a higher-PREN alloy like 317L or even duplex stainless steel can make a big difference.

Lab tests (such as ferric chloride pitting tests) and field data help validate real-world performance. But always interpret results in context: temperature, chloride concentration, and even surface finish play a role in how your marine stainless steel will behave.

Troubleshooting Pitting and SCC in Service

Noticed rust spots, leaks, or cracks on your 316 equipment? Here’s a practical troubleshooting workflow to help you diagnose and fix the problem before it escalates:

- Verify the alloy and surface finish (is it really marine grade 316 stainless steel or an equivalent?).

- Inspect design for crevices, tight joints, or stagnant areas where chlorides can concentrate.

- Assess the environment: check chloride levels, temperature, and exposure to cleaning chemicals.

- Look for surface contamination—iron particles from tools or nearby carbon steel can trigger corrosion.

- Examine welds for cleanliness and proper passivation; weld decay can start SCC or pitting.

- Review maintenance and cleaning procedures—are you using the right chemicals and frequency?

| Observed Symptom | Likely Cause | Corrective Action |

|---|---|---|

| Pinpoint pits or brown stains | Chloride pitting, poor drainage, or iron contamination | Increase Mo/N content (upgrade to 317L or duplex stainless steel), improve drainage, enhance passivation |

| Cracking at welds or bends | Stress corrosion cracking (SCC) from residual or external stress in chloride environment | Reduce stress, use low-stress fabrication, consider duplex stainless steel for higher SCC resistance |

| General rust or tea staining | Poor maintenance, surface contamination, or unsuitable cleaning agents | Clean with approved products, avoid chlorides, repassivate surfaces |

| Corrosion under gaskets or deposits | Crevice corrosion due to oxygen starvation | Redesign joints, use non-absorbent gaskets, regular cleaning |

No stainless steel is rust-proof; context and maintenance matter. Even marine grade 316 stainless steel can fail if exposed to the wrong conditions or neglected over time.

In summary, while 316 and 316L stainless steel properties offer robust corrosion resistance for most applications, certain scenarios—especially those involving high chloride exposure, stress, or poor design—can challenge even the best alloys. When in doubt, upgrading to a higher-alloyed material like duplex stainless steel can provide added peace of mind, especially for mission-critical or marine applications.

Next, we’ll look at fabrication and welding best practices to help you protect your investment and maintain that corrosion resistance for the long haul.

Fabrication and Welding Practices That Protect 316

Welding 316 vs 316L Without Compromising Corrosion Performance

When you’re fabricating with stainless steel ss 316, you want every weld and bend to preserve the material’s renowned corrosion resistance and mechanical integrity. But how do you get there? Imagine you’re assembling a pressure vessel or a food processing line—one poor weld or fabrication shortcut can undermine the entire project. Let’s walk through the best practices for machining, forming, and welding 316 and 316L, so you can avoid the common pitfalls and deliver reliable results every time.

- Always use low-carbon 316L for welded assemblies. This minimizes the risk of sensitization (chromium carbide precipitation at grain boundaries), which can lead to intergranular corrosion. If you’re welding thick sections or can’t perform post-weld annealing, 316L is your best bet.

- Prepare surfaces meticulously before welding. Remove any oils, dust, or iron contamination. Even small traces of carbon steel can trigger rust or compromise the weld’s corrosion resistance.

- Choose the right welding method. TIG (GTAW) welding produces the cleanest, most corrosion-resistant joints, especially for visible or sanitary applications. MIG (GMAW) is faster and still reliable, while stick welding is best reserved for non-critical, low-stress applications.

- Control heat input carefully. Stainless steel heat resistance is excellent, but 316 ss thermal conductivity is lower than carbon steel. This means heat builds up quickly at the weld—too much can cause distortion, warping, or even loss of corrosion resistance. Use intermittent welding and allow cooling between passes.

- Use matching or slightly over-alloyed filler metals. ER316L filler is the industry standard for both 316 and 316L base metals, ensuring welds that match the corrosion performance of the parent material.

Filler Metal Recommendations and Heat Input Control

Sounds technical? Here’s a practical example: If you’re welding a 316L tank for chemical storage, specify ER316L filler wire to maintain both strength and corrosion protection. For thicker sections or high-temperature service, consult your filler supplier for advice—sometimes a higher-alloyed wire (like 317L) is warranted for extra pitting resistance. Always keep your heat input moderate; 316 ss thermal conductivity means the weld zone retains heat, so move steadily and avoid lingering in one spot.

| Fabrication Pitfall | Prevention Step |

|---|---|

| Weld decay (intergranular corrosion) | Use 316L for welded assemblies; avoid overheating; use proper filler |

| Distortion or warping | Limit heat input; allow cooling between passes; use fixturing |

| Surface contamination (rust spots) | Clean tools and surfaces; never use unprotected carbon steel tooling |

| Poor corrosion resistance at weld | Passivate welds after fabrication; use ER316L or higher-alloy filler |

| Cracking during forming | Use generous bend radii; anneal if needed; avoid cold working beyond limits |

Finishing and Passivation Steps That Actually Help

After the last weld is laid or the final bend is made, don’t skip the finishing steps. Passivation is essential—it removes iron particles and restores the chromium-rich oxide layer that gives stainless steel its corrosion resistance. This can be done using traditional nitric acid or safer, modern alternatives like electrolytic weld cleaning (for example, the TIG Brush system), which is faster and safer for operators.

- Clean welds and surfaces after fabrication. Use approved passivation methods to remove contaminants and restore the passive film.

- Inspect for discoloration or heat tint. Any visible oxidation should be removed, as it can indicate a compromised passive layer.

- For critical applications, specify a post-weld passivation step on your drawings and purchase orders.

Never use carbon steel tools on stainless without protection—cross-contamination can lead to rust and undermine your investment in corrosion resistance.

Machining and Forming Tips for 316 and 316L

When machining or forming 316 stainless, remember: it’s tougher than 304 and work-hardens quickly. Carbide-tipped tools are preferred for longer life and better finishes. Use plenty of coolant to control temperature, since stainless steel heat resistance is high but 316 ss thermal conductivity is relatively low—excess heat can cause work hardening or tool wear. For forming, allow for generous bend radii and anticipate springback. Annealing between forming steps can help if you’re making tight bends or complex shapes.

- Use sharp, carbide tools and moderate speeds for machining.

- Apply ample coolant to avoid heat buildup and maintain surface quality.

- Plan for larger bend radii—tight bends can cause cracking, especially in cold-worked material.

- Anneal if needed between heavy forming operations to restore ductility.

By following these fabrication and welding practices, you’ll preserve the corrosion resistance, mechanical strength, and long-term value of your stainless steel ss 316 assemblies. Up next, we’ll guide you through the standards and documentation you need to specify and order 316 with confidence.

Standards and Designation Cross Reference for 316

Cross-referencing AISI, ASTM, ASME, UNS, EN, and JIS for 316 Stainless Steel

Ever tried to order stainless steel and found yourself wading through a sea of codes—AISI 316, s31600, astm a240 type 316, t316 stainless steel, a4 stainless steel, sus316? Sounds confusing? You’re not alone. Knowing which designation to use is critical for getting the right material, avoiding costly mix-ups, and ensuring compliance with global standards.

| System/Standard | Designation | Typical Product Forms | Finish Conditions | Reference/Notes |

|---|---|---|---|---|

| AISI (American Iron and Steel Institute) | 316, 316L, 316H | Sheet, plate, bar, pipe, tube, wire | 2B, BA, HRAP, brushed | Common US grade names (e.g., aisi 316 ss) |

| UNS (Unified Numbering System) | S31600 (316), S31603 (316L), S31609 (316H) | All product forms | As above | Cross-reference for procurement (e.g., s31600) |

| ASTM (American Society for Testing and Materials) | ASTM A240 Type 316 (plate/sheet/strip), A312 (pipe), A276 (bar), A193 (bolting) | Sheet, plate, strip, bar, pipe, tube, fasteners | 2B, BA, HRAP, others | Specify product type and condition (e.g., astm a240 type 316) |

| ASME (American Society of Mechanical Engineers) | SA-240 (plate/sheet/strip), SA-312 (pipe) | Sheet, plate, pipe, tube | 2B, BA, HRAP | Boiler & pressure vessel code |

| EN (European Norm) | EN 1.4401 (316), EN 1.4404 (316L), EN 1.4436 (high Mo) | Sheet, plate, bar, tube | 2B, BA, brushed | Europe, UK, ISO harmonized |

| JIS (Japanese Industrial Standard) | SUS 316, SUS 316L | Sheet, plate, bar, tube, wire | 2B, BA, HRAP, others | Japan, Asia (e.g., sus 316 or sus316) |

| ISO | X5CrNiMo17-12-2 (316), X2CrNiMo17-12-2 (316L) | All forms | 2B, BA | International standardization |

What to Call Out on Drawings and Purchase Orders (POs)

Imagine you’re finalizing a drawing or sending a PO. What details do you need to ensure you get exactly the right aisi 316 ss or sus 316 material? Here’s a practical checklist to help you avoid surprises:

- Grade/Designation: Specify the exact grade (e.g., 316, 316L, s31600, sus316) and any variant (L, H, Ti)

- Product Specification: Reference the correct standard (e.g., astm a240 type 316 for plate/sheet, a276 for bar)

- Condition/Finish: Call out 2B, BA, HRAP, brushed, or custom finish as required

- Dimensions/Tolerances: Thickness, width, length, OD/ID for tube/pipe, and any special tolerances

- Testing: Request NDT (non-destructive testing), PMI (positive material identification), or intergranular corrosion test if needed

- Certification: Ask for mill test certificates, heat/lot numbers, and compliance with applicable specs

For example, a complete callout for a pressure vessel plate might read: “ASTM A240 Type 316, 2B finish, 10 mm x 1500 mm x 3000 mm, s31600, with PMI and mill certs.” This ensures the supplier delivers the correct t316 stainless steel product, in the right condition, with all required documentation.

Heat Treatment and Product Form Specifications

Heat treatment and surface finish are just as important as grade and standard. For most applications, 316 and 316L are supplied in the annealed condition for maximum corrosion resistance and ductility. If you need a specific surface—like 2B for industrial use or BA for architectural panels—always specify it. HRAP (hot rolled, annealed, pickled) is common for plate and bar, while brushed or polished finishes suit visible surfaces.

Remember, type 316 cannot be hardened by heat treatment, but it can be strengthened by cold working. If your application requires special mechanical properties, clarify any additional cold work or temper requirements on your PO.

Key takeaway: The more detail you provide—grade, standard, finish, dimensions, and tests—the more likely you’ll get the exact stainless steel ss 316 you need, whether it’s s31600, sus 316, or any other global variant.

With your standards and documentation lined up, you’re ready to tackle cost, availability, and procurement—topics we’ll address in the next section to help you manage your project from order to inspection.

Cost, Availability, and Procurement-Ready Checklists for 316 Stainless Steel

Price Factors That Move 316 Up or Down

When you’re planning a project with stainless steel ss 316, have you noticed how the price can swing dramatically from one quote to the next? Sounds frustrating, but there’s a logic behind it. The cost of 316 stainless steel is shaped by a blend of raw material prices, alloy surcharges, processing, and even the finish you select. Let’s break down the biggest levers:

| Cost Variable | Impact on Price | Notes |

|---|---|---|

| Nickel & Molybdenum Surcharges | High | Nickel is the key driver; a US$1,000/ton swing in nickel can shift 316 prices by ~7%. Molybdenum adds another 3% per $500/ton change. |

| Finish Type | Medium | 2B and mill finishes are most economical; polished or brushed surfaces add processing costs. |

| Thickness & Size | Medium to High | Standard gauges are cheaper. Custom or non-standard sizes require extra handling and may increase scrap. |

| Tolerances | Low to Medium | Tighter tolerances mean more rework and inspection—relaxing non-critical tolerances can cut costs. |

| Test & Certification Requirements | Low to Medium | PMI, corrosion tests, or extra certs add to the price, especially for critical applications. |

| Market Conditions | High | Supply chain disruptions, bulk discounts, and order size all affect final price. |

Keep in mind, the stainless steel 316 price per ton also includes processing, surface treatment, and surcharges—so finished product costs are typically 40–50% higher than raw material alone.

Stock Forms and Availability Trade-Offs

Ever wonder why some forms—like 316 stainless steel pipe or plate—are readily available, while others have long lead times? Here’s what’s going on:

- Standard products (sheet, plate, pipe, bar): Most stainless steel 316 suppliers keep common sizes in stock, which means better pricing and faster delivery.

- Custom or non-standard sizes: May require mill runs or special handling, increasing both cost and lead time.

- Finish choices: 2B and mill finishes are fastest to source; mirror or custom textures can add weeks to delivery.

- Order quantity: Bulk orders (e.g., >50 tons) unlock better prices per pound or per ton, but require more upfront investment.

To optimize both cost and availability, try consolidating thicknesses, choosing standard dimensions, and accepting the most common finish that meets your needs.

Purchase Order and Inspection Documentation

Imagine placing an order and receiving the wrong material, finish, or paperwork. To avoid costly mistakes, use a purchase-order checklist and inspection test record (ITR) to keep everything organized:

| Purchase Order Checklist |

|---|

|

For larger or regulated projects, an ITR (Inspection Test Record) helps you track compliance and documentation:

| Document | Heat/Lot Number | Certification | Inspector/Sign-off |

|---|---|---|---|

| Mill Test Certificate | 12345 | EN 10204 3.1 | QA Manager |

| PMI Report | 12345 | Pass | Lab Tech |

| Corrosion Test (if required) | 12345 | ASTM G48 | Inspector |

By following these checklists, you’ll reduce surprises, keep your procurement process on track, and ensure you get the right 316 stainless steel price per pound or stainless steel 316 price per ton for your needs. And if you’re ever unsure, ask your stainless steel 316 supplier for the latest 316l stainless steel price and documentation before you commit.

Key takeaway: Control costs and avoid delays by standardizing sizes, choosing common finishes, and double-checking your order details. The smarter your procurement process, the more predictable your project budget.

Once your procurement checklist is complete, you’re ready to finalize your grade selection and move to the final step: making an informed, environment-aware material choice for your application.

Actionable Selection Guidance

Material Selection Roadmap for Chloride Environments

Staring at a long list of stainless steel grades and feeling unsure? Let’s simplify your decision. When your project faces exposure to chlorides, heat, or tough fabrication, the right type of 316 stainless steel can make or break performance. Here’s a straightforward path to help you choose:

- Assess the environment: Is your application exposed to saltwater, chemicals, or cleaning agents? If yes, prioritize corrosion resistance.

- Consider fabrication needs: Will your parts require extensive welding or forming? If so, low-carbon grades are safer.

- Evaluate service temperature: Will your component operate above 500°C? High-temperature strength becomes critical.

- Check regulatory and industry standards: Are there specific codes or certifications required for your sector (e.g., ASME, FDA, marine)?

- Balance cost and availability: Is lead time or price a key factor? Some grades are more widely stocked than others.

Balancing Weldability, Strength, and Corrosion Resistance

Imagine you’re building marine hardware, a chemical tank, or medical equipment. The right grade depends on your priorities. Use the table below to match your scenario to the recommended stainless steel 316 type:

| Environment/Requirement | Recommended Grade | Why Choose? | 316 Stainless Steel Temperature Limits |

|---|---|---|---|

| General corrosion, light welding | 316 | Good all-around; suitable for basic marine, food, or pharma use | Up to ~550°C |

| Heavy welding, aggressive chemicals | 316L | Low carbon = best weldability; resists intergranular corrosion | Up to ~550°C |

| Continuous high temperature (boilers, heat exchangers) | 316H | Higher carbon for creep strength and durability at elevated temps | Up to ~870°C |

| Severe chlorides, pitting risk | 317L or Duplex | Higher Mo/N for best pitting/crevice corrosion resistance | Varies (consult supplier) |

- Is 316L stainless steel good? Absolutely, especially for welded assemblies in aggressive environments—it’s the industry standard for tanks, piping, and medical devices where corrosion at welds must be avoided.

- Choose 316H for power generation or industrial equipment exposed to high heat and pressure.

- For the harshest chloride exposures, step up to 317L or duplex grades for extra peace of mind.

Next Steps to Prototype and Validate

Once you’ve selected the right grade, how do you turn your decision into a real-world part? Here’s a checklist to move from selection to prototype:

- Finalize your grade and finish (e.g., 316L, 2B or brushed finish).

- Confirm tolerances, thickness, and fabrication process (machining, sheet forming, welding).

- Engage a prototyping partner with stainless steel expertise. For welded 316 and 316L assemblies, XTJ Rapid Prototyping Services tops the list—offering complimentary DFM (Design for Manufacturability) reviews, ISO 9001:2015 quality control, and fast turnaround for marine, medical, and industrial projects alike.

- Validate your design: Request DFM feedback, confirm achievable finishes and tolerances, and review inspection criteria before committing to production. Not sure where to start?

- If you have in-house capability, benchmark your process against industry best practices—especially for welding and finishing.

-

Recommended partners for 316 prototyping:

- XTJ Rapid Prototyping Services – DFM feedback, ISO-certified, CNC and sheet forming

- Local specialty fabrication shops – for custom or urgent needs

- In-house engineering teams – when you have the equipment and expertise

Key takeaway: The best results come from matching your grade to the environment and process—then validating your design with a trusted prototyping partner. Is 316L stainless steel good? For most welded and corrosion-critical applications, it’s the gold standard.

With your material selected and your prototyping strategy in place, you’re set to move confidently from concept to finished part—knowing your stainless steel 316 choice is backed by sound engineering and real-world data.

Frequently Asked Questions About Stainless Steel SS 316

1. What is the main difference between stainless steel SS 316 and 304?

SS 316 contains molybdenum, which provides much better resistance to chlorides and harsh chemicals than 304. This makes 316 ideal for marine, chemical, and food processing applications, while 304 is suitable for less aggressive environments.

2. Why is 316 stainless steel called marine grade?

316 is known as marine grade because its molybdenum content significantly boosts resistance to pitting and crevice corrosion in saltwater and chloride-rich environments. This makes it the top choice for boat fittings, dock hardware, and coastal architecture.

3. When should I use 316L instead of standard 316 stainless steel?

316L is best for welded assemblies or parts exposed to high corrosion risk at welds. Its lower carbon content prevents carbide precipitation during welding, maintaining corrosion resistance without requiring post-weld heat treatment.

4. How does 316H differ from 316 and 316L stainless steel?

316H has higher carbon content than 316 or 316L, giving it superior creep strength at elevated temperatures. It's recommended for applications like boilers and heat exchangers where components face prolonged high-heat exposure.

5. What are the most common finishes for 316 stainless steel sheet?

The most common finishes are 2B mill finish (smooth and lightly reflective), brushed (No. 4), and bead-blast. The finish affects both corrosion resistance and appearance, so it's important to specify your requirements when ordering.

-

Posted in

316 stainless steel, marine grade stainless, ss 316, stainless steel finishes, stainless steel properties