18-8 Stainless Steel Vs 304 Vs 316: Make The Right Choice Fast

Understand 18 8 Stainless Steel the Right Way

What is 18/8 Stainless Steel in Real-World Labeling?

Ever wondered what those "18/8" or "18-8" labels really mean on your kitchenware or fasteners? Sounds complex, but the answer is straightforward: 18-8 stainless steel is a shorthand notation describing a family of stainless steel grades containing approximately 18% chromium and 8% nickel by weight. This composition is what gives the alloy its excellent corrosion resistance, strength, and formability. However, 18-8 is not a single, exact specification—it’s a convenient trade term used across industries to represent a group of austenitic (300-series) stainless steels, most commonly AISI 304 or its equivalents like SUS304 and UNS S30400.

When you see "18/8" on a product, it usually means the material meets the general chemistry of 18% chromium and 8% nickel, but the precise properties and tolerances will depend on the referenced standard—such as ASTM A240 for plate and sheet, or ASTM A276 for bar and rod. For international mapping, ISO 15510 helps align these grades globally.

| Nomenclature | Typical Use | Standardized Grade | Product Forms | Source Standard |

|---|---|---|---|---|

| 18-8 / 18/8 | Consumer/trade shorthand | AISI 304 (or equivalent) | Fasteners, utensils, enclosures | ASTM A240/A276 |

| AISI 304 | Engineering/industrial | UNS S30400 | Sheet, plate, bar, tube, wire | ASTM A240/A276 |

| SUS304 | Japanese/Asian markets | Equivalent to AISI 304 | All product forms | ISO 15510 |

| UNS S30400 | Unified Numbering System | AISI 304 | All product forms | ASTM A240/A276 |

How 18-8 Relates to 304 and SUS304 Across Standards

So, what is 18-8 stainless steel in the context of global standards? Think of "18-8" as a nickname for a family of stainless steels—most often corresponding to 304 stainless steel under the American Iron and Steel Institute (AISI) system. In Japanese and some Asian markets, the same composition is labeled as SUS304. The Unified Numbering System (UNS) designates this alloy as S30400. While the shorthand "18-8" focuses on the chromium and nickel content, only the full grade name (like AISI 304 or SUS304) ties the product to a published standard with detailed chemical, mechanical, and physical requirements.

This distinction is critical: the stainless steel 18 8 meaning is not a guarantee of exact composition or properties. Always check the mill test report (MTR) or product documentation to confirm the precise grade and compliance.

Where 18-8 Excels and Where It Falls Short

- Flatware & Kitchenware: Hygienic, easy to clean, and resists food acids—ideal for utensils, cookware, and appliances.

- Fasteners: Excellent for indoor, mildly corrosive, or high-humidity environments—think HVAC, furniture, and general construction.

- Medical & Food Equipment: Non-reactive and easy to sterilize, making it a top choice for medical trays, surgical tools, and food processing.

- Architectural & Enclosures: Used in handrails, facades, and electronic housings for its appearance and corrosion resistance.

But 18/8 stainless steel is not perfect for every situation. It can show signs of corrosion when exposed to chlorides (like salt), so it’s not recommended for marine or highly corrosive environments. In those cases, specialized grades like 316 may be required.

18-8 is a family shorthand; verify exact grade and standard on purchase documents.

In summary, what is 18 8 stainless steel? It’s a versatile, corrosion-resistant alloy family—most often AISI 304 or SUS304—widely used in fasteners, kitchenware, and industrial equipment. But always remember: the shorthand tells you the general chemistry, not the certified grade. For critical projects, check the standard and ask for documentation.

Composition Ranges, Standards, and Naming Alignment

Chemical Composition Ranges You Should Actually Use

When you’re sourcing or specifying 304 stainless steel, have you ever wondered what the real numbers behind “18-8” actually are? The shorthand tells you there’s about 18% chromium and 8% nickel, but engineers and quality teams know that the actual chemistry is more tightly controlled—and those details matter for performance and compliance.

Let’s break down the certified composition ranges for 304 (UNS S30400), 304L (UNS S30403), and 304LN (UNS S30453) stainless steels, based on industry standards like ASTM A240/A276 and ASTM A240. This is where the stainless steel 18 8 meaning gets real—turning trade shorthand into certifiable numbers.

| Element | 304 (S30400) | 304L (S30403) | 304LN (S30453) | Reference Standard |

|---|---|---|---|---|

| Carbon (C), max | 0.08% | 0.030% | 0.030% | ASTM A240/A276 |

| Manganese (Mn), max | 2.00% | 2.00% | 2.00% | ASTM A240/A276 |

| Phosphorus (P), max | 0.045% | 0.045% | 0.045% | ASTM A240/A276 |

| Sulfur (S), max | 0.030% | 0.030% | 0.030% | ASTM A240/A276 |

| Silicon (Si), max | 1.00% | 1.00% | 1.00% | ASTM A240/A276 |

| Chromium (Cr) | 18.0–20.0% | 18.0–20.0% | 18.0–20.0% | ASTM A240/A276 |

| Nickel (Ni) | 8.0–10.5% | 8.0–10.5% | 8.0–10.5% | ASTM A240/A276 |

| Nitrogen (N) | — | — | 0.10–0.15% | ASTM A240/A276 |

| Iron (Fe) | Balance | Balance | Balance | ASTM A240/A276 |

Notice how the certified composition of 304 stainless steel is more specific than the “18-8” label? These numbers are what you’ll see on a mill test report (MTR), and they’re your assurance that the 304 stainless steel material meets the necessary requirements for your application.

UNS and AISI Mapping for 18-8 and 304

If you’re searching for sus304 stainless steel or 304 18 8 stainless steel, you’ll notice that naming can get confusing. Here’s how it all aligns:

- 304 (AISI 304, UNS S30400): The most common 18-8 grade, used worldwide.

- 304L (UNS S30403): Low-carbon version for improved weldability.

- 304LN (UNS S30453): Low-carbon, nitrogen-strengthened variant for higher strength.

- SUS 304: Japanese designation, equivalent to AISI 304.

All these designations point to similar chemistry, but the exact limits and tolerances are set by the product’s governing standard. That’s why verifying the UNS or AISI number on the paperwork is so important, especially when matching international specs.

How Product Form Standards Affect Chemistry

Did you know that the standard you order under—like ASTM A240 for plate or ASTM A276 for bar—can affect minor details of the chemistry or allowable tolerances? For example, drawn tubes might have slightly different carbon limits than plate. This is why it’s essential to confirm not just the grade, but also the product form and standard on your order.

Impurities like phosphorus and sulfur are tightly limited to maintain corrosion resistance and mechanical properties, while nitrogen (in 304LN) is used to boost strength without raising carbon content. These minor elements can make a big difference in performance, especially for demanding environments.

-

How to read a Mill Test Report (MTR):

- Check the heat number for traceability

- Verify the UNS or AISI designation matches your spec

- Confirm the product form standard (e.g., ASTM A240, A276)

- Review the chemical composition—does it fall within the certified range?

- Look at mechanical properties for compliance

Don’t rely on trade names alone—always confirm the certified composition and product standard for your 304 stainless steel material.

Next, we’ll see how these certified chemistries translate into real-world mechanical properties and what that means for your application.

Mechanical Properties That Matter for 18 8

Strength and Hardness Ranges by Product Form

When you’re choosing 18-8 stainless steel for your next project, it’s not just about chemistry—the real-world performance depends on mechanical properties like strength, ductility, and hardness. But did you know these properties can shift depending on whether you’re using plate, sheet, or bar stock? Let’s break down the certified numbers so you can make confident decisions for your application.

| Property | Sheet/Plate (ASTM A240) | Bar (ASTM A276) | Reference |

|---|---|---|---|

| Yield Strength (min) | 205 MPa (30 ksi) | 205 MPa (30 ksi) | ASTM A240/A276 |

| Tensile Strength (min) | 515 MPa (75 ksi) | 515 MPa (75 ksi) | Same as above |

| Elongation (min) | 40% | 40% | Same as above |

| Brinell Hardness (max) | 201 HB | 201 HB | Same as above |

| Rockwell B (max) | 92 HRB | 92 HRB | Same as above |

| Density | 7.93 g/cm³ (0.286 lb/in³) | 7.93 g/cm³ (0.286 lb/in³) | SSM Alloys |

-

Testing standards:

- Yield and tensile strength: ASTM E8

- Hardness: Brinell (HB) or Rockwell B (HRB) conversion

- Elongation: Standard 50 mm specimen

These numbers reflect typical 304 stainless steel properties in the annealed (solution-treated) condition. You’ll notice a consistent minimum for 304 stainless steel yield strength and tensile strength across both plate and bar, but always check your mill test report (MTR) for the exact values supplied with your batch.

Cold Work Effects on Strength and Magnetism

Ever wondered why some stainless fasteners feel a little magnetic or seem harder than others? That’s the impact of cold working. When 304 stainless steel is cold-rolled, drawn, or formed, its strength and stainless steel hardness increase dramatically—sometimes nearly doubling the yield and tensile strength compared to the annealed state.

- Cold working boosts both 304 ss yield strength and tensile strength

- It reduces ductility (the metal becomes less stretchable before breaking)

- Surface finish often improves, but internal residual stresses may increase

- Cold work can induce slight magnetism in otherwise nonmagnetic 304

So, is 304 stainless steel magnetic? In its annealed form, it’s generally nonmagnetic. But after significant cold work—like in drawn wire or heavily formed components—you may notice a weak magnetic pull. This doesn’t affect corrosion resistance, but if nonmagnetic properties are critical, specify annealed material or consider specialized grades.

Heat Treatment and Annealing Considerations

Unlike some steels, 304 stainless steel cannot be hardened by heat treatment. Annealing (heating and slow cooling) is used to restore ductility and remove residual stresses after cold work, bringing the material back to its original, nonmagnetic state. This process is essential when you need maximum formability or want to eliminate internal stresses from fabrication.

Keep in mind, continuous use in the 800–1580°F (427–860°C) range is not recommended if corrosion resistance is critical, as this can cause sensitization.

Verify the specified standard and condition on the MTR—properties depend on both.

Understanding 304 stainless density, 304 stainless steel hardness, and how processing affects 304 stainless steel yield strength gives you the tools to select the right material for your application. Next, let’s see how these mechanical traits hold up when facing real-world corrosion challenges and when it’s time to consider upgrading to 316.

Corrosion Behavior and When to Choose 316

When 18-8 Works and When to Consider 316

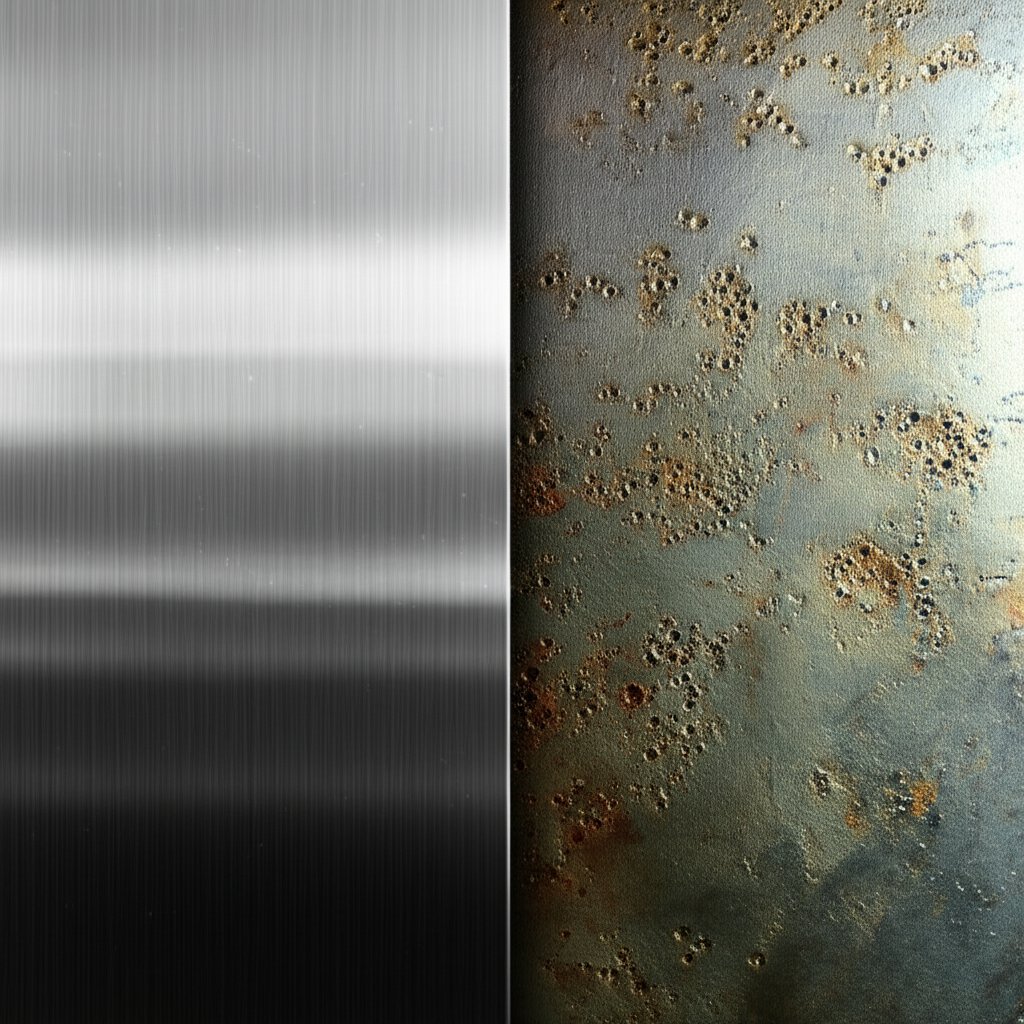

Imagine you’re choosing between 304 vs 316 stainless steel for a new project. It’s tempting to default to the familiar 18-8 (304), but have you considered the environment your part will face? While 18-8 stainless steel, often represented by 304, offers solid corrosion resistance for most indoor, mildly corrosive, and general-purpose settings, it isn’t a universal solution—especially where chlorides or harsh chemicals are present.

For everyday use—kitchenware, architectural trim, indoor fasteners—304 is cost-effective and reliable. But in demanding applications like marine hardware, chemical processing, or food equipment exposed to salt, the difference between 304 and 316 stainless steel becomes clear. 316 stainless steel contains molybdenum, which drastically improves resistance to pitting and crevice corrosion, especially in chloride-rich environments.

| Attribute | 18-8 / 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Chloride Resistance | Moderate (can pit in saltwater or chlorine) | High (outperforms 304 in marine, pool, and chemical settings) |

| General Corrosion Resistance | Excellent in most atmospheres, food, and mild chemicals | Superior, especially against acids and chlorides |

| Pitting/Crevice Corrosion | Susceptible in presence of chlorides | Much less prone due to molybdenum content |

| Temperature Tolerance | Good up to 870°C (1600°F) | Similar, but retains resistance at slightly higher temps |

| Typical Uses | Kitchenware, indoor fasteners, appliances, food processing | Marine, pool hardware, chemical tanks, medical devices |

| Cost Band | Lower (most economical austenitic stainless) | Higher (due to alloying elements) |

Pitting and Crevice Corrosion in Chloride Service

Ever noticed brown spots or tiny pits on stainless steel after saltwater exposure? That’s pitting corrosion. Chloride ions, even in small amounts (think de-icing salts, seawater, or pool chemicals), can break down the passive film on 304, initiating rapid pit growth. The risk is especially high in crevices, seams, or under deposits where oxygen is limited.

- 304 stainless steel vs 316: 304 is more likely to pit in salty or chlorinated environments.

- 316 vs 304 stainless steel: 316’s added molybdenum acts as a shield, greatly reducing pit formation and propagation.

- For critical marine, coastal, or chemical applications, 316 is the safer bet—even at a higher upfront cost.

So, does 304 stainless steel rust? In most indoor or mildly corrosive settings, it resists rusting well. But in chloride-heavy environments, 304 can and does develop corrosion—sometimes quickly, especially if not cleaned or passivated.

Cleaning and Passivation Practices for Longevity

Want your stainless to last? Maintenance and finishing matter as much as grade selection. Even 316 stainless steel benefits from proper cleaning and passivation, but for 304, these steps are essential to prevent premature corrosion:

- Rinse thoroughly after saltwater or chemical exposure

- Avoid chloride-based bleaches and cleaners

- Consider periodic passivation to ASTM A967 standards to restore the protective oxide film

- For critical or high-purity applications, electropolishing can further enhance corrosion resistance

If failures are pitting-driven, evaluate 316 even at higher cost.

In summary, the choice between 304 vs 316 stainless comes down to environment. For most indoor, food, or architectural uses, 18-8/304 is a solid, economical choice. But if your application risks exposure to salt, chemicals, or harsh cleaning, 316 stainless steel vs 304 is a conversation you can’t afford to skip. Next, we’ll explore how to select the right variant and why low-carbon or nitrogen-strengthened options may tip the scales for welded assemblies or high-strength needs.

Variants 304L and 304LN Made Simple

Why and When to Specify 304L for Welding

When you’re working with 18-8 stainless steel and need to weld, have you ever worried about hidden corrosion at the welds? This is where 304L steps in. The "L" stands for "low carbon," and this subtle tweak makes a huge difference for welded assemblies. By reducing carbon content to a maximum of 0.03%, 304L dramatically lowers the risk of sensitization—a process where chromium carbides form at grain boundaries during welding, depleting corrosion-fighting chromium and leaving those areas vulnerable to intergranular corrosion (sometimes called "weld decay").

How do you know if your material is at risk? Sensitization is most likely when the steel is held at temperatures between 425–870°C (800–1600°F), as happens in welding. This can be verified using industry tests such as ASTM A262, which screens for susceptibility to intergranular attack. If your application involves food equipment, piping, or tanks where cleanliness and corrosion resistance are critical, specifying 304L is a smart move.

Is 304 stainless steel food grade? Absolutely—both 304 and 304L are widely accepted as food-contact safe, but 304L is the preferred choice when welding is involved, ensuring long-term durability and hygiene.

How 304LN Balances Corrosion and Strength

Need higher strength without sacrificing corrosion resistance? That’s where 304LN comes in. This variant keeps the low carbon of 304L but adds nitrogen (typically 0.10–0.16%) to boost strength and preserve ductility. Nitrogen acts as a solid solution strengthener, making 304LN an excellent fit for welded structures that need to handle higher loads or stress, such as pressure vessels, piping in chemical plants, or architectural supports.

Compared to standard 304, 304LN offers improved yield strength while maintaining similar corrosion resistance and formability. This is especially valuable when you want the weldability of 304L but need extra mechanical performance—without stepping up to more expensive alloys. Remember, always confirm the chemistry and mechanicals for 304LN on the mill test report (MTR) to ensure compliance with your project’s requirements.

WPS and Post-Weld Surface Treatment Considerations

Welding isn’t just about picking the right filler or process—it’s about what comes after, too. Even with 304L or 304LN, best practice is to follow up with:

- Pickling: Removes heat tint and surface oxides formed during welding.

- Passivation: Restores the protective chromium oxide layer, especially important for food, pharma, or chemical service (typically to ASTM A967 or A380 standards).

- Cleaning: Rinse thoroughly and avoid chloride-based cleaners to maintain corrosion resistance.

These steps help maintain the integrity of your welds and the overall corrosion resistance of the assembly. For critical applications, require documentation of post-weld cleaning and passivation in your project specs.

- 304L: Best for welded food-contact equipment and piping—reduces risk of weld decay and is the go-to for 304 stainless steel food grade requirements.

- 304LN: Ideal for welded structures needing higher strength while still resisting intergranular corrosion.

- Standard 304: Suitable for non-welded, general service where high weldability isn’t critical.

If you weld near chloride exposure, pair 304L with disciplined post-weld cleaning and passivation.

In summary, understanding the differences among these types of stainless steel helps you balance weldability, corrosion resistance, and strength. Whether you’re selecting for grades of stainless steel in food, pharma, or industrial projects, matching the right variant to your process and environment is crucial. Next, we’ll turn this technical know-how into practical tips for sector-specific applications—so you can put the right material to work, every time.

Practical Applications Across Key Industries

Cookware and Flatware Best Practices

When you open your kitchen drawer or reach for a pot, chances are you’re using something made from 18-8 stainless steel or its close cousin, 304. Why is this material so common? Simple: it resists rust, cleans up easily, and stands up to daily wear. But to keep your flatware, stainless steel cooking utensils, or 18/10 stainless steel cookware looking their best, a few simple habits make all the difference.

- Use gentle, non-abrasive detergents—harsh chemicals can dull the finish and, over time, lead to pitting.

- Avoid soaking in salty or acidic water for long periods; this can cause surface staining, especially in lower-nickel grades.

- Dry promptly after washing to prevent water spots and streaks.

- Handwashing is gentler than dishwashing, especially for premium stainless steel 18 10 cutlery and stainless silverware 18/10 sets (Caraway).

- For cookware, remember: heat performance is driven more by core/cladding (like aluminum or copper layers) than the stainless shell itself.

Fastener Selection and Galling Prevention

Ever had a stainless nut or bolt seize up during installation? That’s thread galling—a common challenge with stainless fasteners like lag bolts and screws. Luckily, a few best practices can prevent costly headaches:

- Apply lubricants (such as PTFE or molybdenum disulfide) to reduce friction and heat.

- Mix nut and bolt grades when possible (e.g., 304 nut with 316 bolt) to reduce the risk of galling.

- Use coarse threads rather than fine threads for less friction.

- Keep threads clean and follow recommended torque specs to avoid over-tightening.

- For coastal or chloride-rich environments, consider upgrading to 316 stainless fasteners for extra corrosion resistance.

Vacuum and Cleanroom Finishing Considerations

In high-purity environments like vacuum chambers or cleanrooms, surface finish and cleanliness are just as critical as material grade. Here’s how to get it right:

- Specify low-outgassing finishes to minimize contamination.

- Require passivation to recognized standards (such as ASTM A967) to remove free iron and enhance corrosion resistance (INOX Passivation).

- Control particulate generation by using smooth, polished surfaces and avoiding sharp edges.

- Document all cleaning and finishing steps for traceability and compliance.

Food and Medical Compliance Essentials

For industries where hygiene and product purity are non-negotiable—think food processing, commercial kitchens, or medical devices—material choice is only the beginning. You’ll want to:

- Specify a smooth, polished surface finish to minimize bacterial adhesion.

- Require passivation to ASTM A967 for all food- or medical-contact parts to restore maximum corrosion resistance.

- Document every cleaning, passivation, and inspection step to satisfy regulatory requirements.

- Choose higher-nickel grades (like 18/10) for enhanced corrosion resistance and long-term shine in high-use settings.

- For stainless steel 18 10 cutlery and medical tools, prioritize both grade and finish for safety and durability.

Process history and surface finish can matter as much as grade.

By tailoring your approach—whether you’re selecting 18/10 stainless steel cookware for a restaurant kitchen or specifying lag bolts for a coastal project—you’ll get the performance, durability, and compliance you need. Next, we’ll look at how to lock in quality and consistency with proven procurement and inspection strategies.

Procurement Quality and Inspection Checklists

How to Write a Clear Stainless Steel PO

When you’re sourcing stainless steel hardware—whether it’s a brushed sheet, a stainless steel bolt, or a full set of stainless steel nuts and bolts—clarity in your purchase order (PO) is non-negotiable. Imagine your project stalling because a shipment doesn’t match your requirements. Sounds frustrating, right? That’s why a precise PO is your first line of defense against costly mix-ups and quality issues.

Here’s what a clear PO for 18-8 stainless steel should always include:

- Exact grade and product form: Specify the UNS designation (e.g., S30400), product form standard (ASTM A240, A276), and finish.

- Certifications required: State that ISO 9001 or equivalent certification is mandatory for the supplier.

- Mill Test Report (MTR): Require a traceable MTR for every batch—this document is your proof that the material matches your spec (Trinity Dynamic).

- No substitutions: Prohibit material substitutions without written approval.

"Supplier must provide a Mill Test Report (MTR) for each shipment, confirm compliance with the exact standard and grade specified, and obtain written approval before making any substitutions."

CoC and MTR Fields to Verify Every Time

Ever received a batch of stainless steel nut bolt hardware and wondered if it’s truly what you ordered? The answer lies in the Certificate of Conformance (CoC) and the Mill Test Report (MTR). These documents are your quality guarantee—if you know what to check.

| Field | What to Look For |

|---|---|

| Supplier Name & ISO Certification | Supplier listed with valid ISO 9001 or equivalent |

| Heat/Lot Number | Unique, matches product markings for traceability |

| UNS Designation | Correct grade (e.g., S30400 for 304/18-8) |

| Product Form Standard | ASTM A240 for plate/sheet, A276 for bar/rod, etc. |

| Chemical Composition | Within certified range for each element |

| Mechanical Properties | Meets or exceeds standard (tensile, yield, elongation) |

| Heat Treatment Condition | Annealed or as specified for your application |

| Surface Finish | Matches your PO (e.g., brushed, polished) |

| Passivation Reference | Noted if required; often ASTM A967 for food/medical use |

Reviewing these details helps you catch errors before they become costly problems—especially in critical applications where stainless steel nut bolt performance can’t be compromised.

Incoming Inspection Steps That Catch Problems

Picture this: your shipment arrives, and you’re eager to get started. But how do you make sure what’s in the crate matches what’s on paper? A robust incoming inspection routine is your best safeguard. Here’s a checklist you can use for stainless screws, bolts, and more:

- Visual ID: Check markings, color, and general appearance for obvious mismatches.

- Dimensions: Measure length, diameter, and thread pitch using calibrated tools.

- PMI (Positive Material Identification): Use handheld XRF or similar tools for alloy verification, if required.

- Hardness Test: Spot-check for correct hardness range per standard.

- Surface Finish Verification: Confirm the finish matches your PO—look for brushing, polishing, or passivation as specified.

- Passivation Confirmation: If passivation is required, request documentation or test for surface iron removal.

- Documentation Archiving: File all MTRs, CoCs, and inspection records for traceability and audits.

Don’t forget: cite the controlling standard (ASTM, ISO, etc.) on your PO and inspection forms. This ensures everyone is aligned on what “good” looks like and reduces disputes if questions arise later.

By combining precise procurement language with thorough verification and inspection, you’ll bridge the gap between specification and delivered quality—protecting your project, your team, and your reputation. Up next, we’ll explore how to turn all this technical diligence into manufacturable designs that work, every time.

Design for Manufacturability and Rapid Prototyping with 18-8 Stainless Steel

Machining Tips for 304 to Reduce Work Hardening

When you move from the drawing board to actual parts, understanding the properties of 18-8 stainless steel is crucial for a smooth manufacturing process. Have you ever noticed how some 300 series stainless steel parts seem tougher to machine than others? That’s because 18-8/304 is notorious for work hardening—the surface gets harder as you cut, making each pass trickier than the last. Sounds challenging, right? Here’s how to stay ahead:

- Use sharp carbide tooling: Carbide tools stay sharper longer and help slice through work-hardened zones efficiently.

- Maintain moderate surface speeds: Too fast and you risk overheating; too slow and you’ll get built-up edge and more work hardening.

- Apply positive rake angles: Positive rake reduces cutting force and heat, minimizing hardening.

- Generous coolant is a must: Coolant keeps the part and tool cool, reduces work hardening, and flushes away chips.

- Keep tool overhang short: A rigid setup prevents chatter and tool deflection, both of which can ruin surface finish and precision.

- Lubricate liberally: Lubricants reduce friction and further control heat—key to protecting both your tools and the 18 8 stainless steel properties.

While 304 is the most commonly machined grade in the 300 series stainless family, remember that 303 stainless is designed for easier machining but sacrifices some corrosion resistance. So, when comparing 303 vs 304 stainless, choose 304 for durability and 303 when machinability is the top concern.

Forming and Tolerancing Guidelines That Stick

Forming 18-8 stainless steel into precise shapes? You’ll notice these alloys are highly ductile, but they can still crack if forced too tightly. Imagine bending a paperclip—pull too far, and it snaps. To avoid problems:

- Use annealed material for best formability—cold work increases strength but reduces ductility.

- Follow bend radii guidance from standard charts—tight bends increase cracking risk.

- Specify tolerances that match the process capability—don’t demand more than the process can deliver.

- Consider springback—stainless returns slightly after bending, so compensate in your design.

-

DFM Checklist for 18-8/304:

- Radius all edges to minimize stress risers and improve cleanability

- Avoid sharp internal corners—these are hard to machine and trap contaminants

- Match tolerances to the chosen process (machining, forming, etc.)

- Specify annealed condition for parts requiring extensive forming

- Call out passivation and surface roughness where hygiene or corrosion resistance is critical

Surface Finish and Passivation for Performance

Finishing touches can make or break your part’s performance—especially for food, medical, or high-purity uses. The natural corrosion resistance of 18-8 stainless steel relies on a passive chromium oxide film, but machining and welding can leave free iron or heat tint that compromise this layer. Here’s what to do:

- Specify passivation to ASTM A967: This removes free iron and restores the protective surface—essential for maximizing stainless steel 18 8 material properties.

- Set surface roughness targets: For hygienic or cleanroom parts, smoother is better. Typical Ra values might be 0.8–1.6 μm for food contact.

- Consider electropolishing: For ultra-smooth finishes and even better corrosion resistance, especially in medical or semiconductor applications.

| Process | Typical Lead Time | Tolerance Range | Surface Finish Options |

|---|---|---|---|

| CNC Machining | 3–10 days | ±0.05 mm or better | Machined, brushed, polished, passivated |

| Injection Molding (plastic mates) | 7–15 days | ±0.1–0.2 mm | Varies by mold; typically textured or polished |

| Die Casting (companion parts) | 10–20 days | ±0.1–0.3 mm | As-cast, machined, or tumbled |

Want to move from concept to part quickly with confidence? XTJ offers rapid prototyping services for 18-8/304 stainless steel, including free DFM feedback to help you optimize your design for both performance and cost. Their ISO 9001:2015 certified team can help you avoid common pitfalls, ensuring your parts meet the highest standards. If you’re comparing providers, keep these criteria in mind:

- XTJ: Rapid DFM review, wide material selection (including 300 series stainless steel), and certified quality control

- Experience with your specific product type (e.g., fasteners, medical, food equipment)

- Proven track record with similar alloys and processes

- Ability to meet your lead time and documentation needs

- Robust quality system and transparent communication

Always choose a partner whose technical capability and quality system fit your needs—price is only one piece of the puzzle.

“Design for manufacturability means thinking about machining, forming, and finishing from day one—don’t let surprises slow you down.”

With these practical guidelines, you can confidently turn your 18-8 stainless steel designs into high-quality, manufacturable parts. Up next, we’ll show you how to wrap up your selection process and move from specification to delivered product with confidence.

Decision Framework and Confident Next Steps for 18-8, 304, and 316 Stainless Steel

Step by Step Selection for 18-8/304 and 316 Stainless Steel

Choosing between 304 stainless steel vs 316 stainless steel can feel overwhelming—especially when performance, cost, and compliance are all on the line. But with a straightforward framework and a side-by-side comparison, you’ll be able to make a defensible, fast decision that matches your environment and budget.

| Attribute | 18-8 / 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Corrosion Environment | Good in most indoor, food, and mild chemical settings | Superior—marine, chemical, and chloride-rich environments |

| Weldability | Excellent; 304L for low carbon, reduced weld decay | Excellent; 316L for welds in corrosive environments |

| Mechanical Ranges (Tensile/Yield, min) | 515/205 MPa (ASTM A240/A276) | 515/205 MPa (ASTM A240/A276) |

| Typical Applications | Kitchenware, hardware, architectural trim, food processing, fasteners | Marine hardware, chemical processing, pharmaceuticals, saltwater exposure |

| Relative Cost Band | Lower—most economical for general use | Higher—premium due to added molybdenum |

Notice how the difference between 316 and 304 stainless steel isn’t about strength or weldability, but about corrosion resistance in tough environments and the resulting cost. For most general-purpose uses, 18-8/304 delivers the best value. But for marine, chemical, or salt-heavy settings, 316 stainless is the clear winner.

- Define your environment: Is there exposure to chlorides (saltwater, de-icers, pool chemicals) or harsh acids?

- Confirm if welding is required: If yes, specify 304L or 316L for reduced risk of weld decay.

- Evaluate required strength and finish: Both offer similar mechanicals. For food, medical, or architectural, finish may matter more than strength.

- Shortlist based on risk and total cost: 304 for most, 316 for aggressive environments or if failure is not an option.

- Lock in standards and inspection: Reference the exact ASTM/ISO standard, require a Mill Test Report, and specify inspection criteria on your purchase order.

Common Pitfalls to Avoid

- Assuming 18-8 vs 316 are interchangeable—316’s molybdenum is a game-changer for chloride-rich or chemical environments.

- Neglecting to specify the “L” variant when welding—this can lead to unexpected corrosion at welds.

- Overlooking documentation—always require a Mill Test Report and check that the supplied grade matches your spec.

- Focusing on upfront cost alone—consider total cost of ownership, especially if corrosion or failure could mean expensive downtime.

For critical or corrosive environments, the cost of 316 is often less than the price of a single failure. Always match grade to environment, confirm standards on paperwork, and don’t skip the MTR review.

From Spec to Delivered Parts: Try Prototyping for Confidence

Still unsure which grade will perform best in your real-world application? Prototyping is a low-risk, high-value way to validate your choice—especially when the stakes are high or the application is new. For rapid prototyping, consider XTJ as a vetted partner. XTJ offers fast DFM (Design for Manufacturability) feedback, a wide material selection including both 18-8/304 and 316 stainless, and ISO 9001:2015 certified quality control—helping you move quickly from design to physical part while catching issues early.

- XTJ: Rapid prototyping with DFM review, certified quality, and experience with both 304 and 316 stainless

- Check for supplier experience in your sector (food, marine, medical, etc.)

- Ensure the provider can supply full documentation and meet your timeline

- Compare capabilities and certifications—choose the fit that supports your project goals

In summary, the 304 stainless steel vs 18/8 debate is usually about nomenclature—both point to the same alloy family. The real decision is 304 vs 316 ss: match your grade to the application, confirm standards and paperwork, and use prototyping to de-risk your choice. By following this framework, you’ll make fast, confident decisions that stand up to scrutiny and deliver long-term value.

Frequently Asked Questions About 18-8 Stainless Steel

1. What does 18-8 stainless steel mean?

18-8 stainless steel refers to a group of austenitic stainless alloys containing about 18% chromium and 8% nickel by weight. This shorthand typically points to grades like AISI 304 or SUS304, known for their corrosion resistance and versatility in kitchenware, fasteners, and more. The exact properties depend on the specific standard and should be verified with a mill test report.

2. Is 18-8 stainless steel the same as 304?

In most cases, 18-8 stainless steel is used as a trade name for AISI 304 stainless steel, especially in the US and Europe. Both have similar chromium and nickel content, but 304 is a specific grade defined by standards, while 18-8 is a general term. Always check documentation to confirm you’re getting certified 304 if required.

3. How is 18-8 stainless steel different from 316?

The main difference is that 316 stainless steel contains molybdenum, which boosts resistance to chlorides and harsh chemicals. While 18-8 (304) works well in most indoor and mild environments, 316 is better for marine, pool, or chemical applications where pitting and crevice corrosion are concerns.

4. Is 18-8 stainless steel food grade and safe for cookware?

Yes, 18-8 stainless steel (typically 304 or 304L) is widely accepted as food grade. It’s used in flatware, cookware, and food processing equipment due to its corrosion resistance and non-reactivity. For welded food-contact parts, 304L is often preferred to reduce corrosion risk at welds.

5. How can I ensure I receive the correct 18-8 stainless steel for my project?

Request a mill test report (MTR) and specify the exact grade (such as UNS S30400 for 304) and standard (like ASTM A240 or A276) in your purchase order. Require ISO-certified suppliers, check chemical and mechanical properties on the MTR, and inspect incoming material for markings, finish, and documentation to confirm compliance.

-

Posted in

18-8 stainless steel, 304 vs 316 stainless, corrosion resistance, stainless steel grades, stainless steel properties