Titanium Metal: 10 Essential Points For Smarter Decisions

Understanding Titanium Metal at a Glance

What Titanium Metal Is and Why It Matters

When you hear about titanium metal, you might picture aerospace parts or medical implants—but what exactly is it, and why is it so valuable? Titanium is a transition metal and a standout performer among the elements, thanks to its remarkable combination of low density, high strength, and outstanding resistance to corrosion. These traits make it a go-to material in industries where performance and reliability are non-negotiable, from jet engines to surgical devices. Imagine a metal that’s as strong as steel but nearly half as light, and you’ll start to see why titanium metal is a strategic choice for demanding applications.

Where Ti Sits on the Periodic Table

To truly understand titanium, let’s look at its place on the titanium periodic table. Titanium is represented by the symbol Ti and is classified as a transition metal in group 4, period 4. Its titanium atomic number is 22, which means each atom has 22 protons. The titanium electron configuration—[Ar] 3d2 4s2—informs its chemical behavior, including its ability to bond in a variety of oxidation states and form a stable, self-healing oxide layer. This electron structure is at the heart of what gives the titanium element its unique combination of strength and corrosion resistance.

| Term | Definition |

|---|---|

| Symbol | Ti |

| Atomic Number | 22 |

| Family | Transition Metal (Group 4) |

| Standard State | Solid |

| Color | Silvery grey-white |

| Electron Configuration | [Ar] 3d2 4s2 |

- High specific strength (strong yet lightweight)

- Spontaneous, passive oxide layer for corrosion resistance

- Biocompatible—well-tolerated by the human body

- Non-magnetic and low thermal conductivity

- Versatile oxidation states for diverse chemical uses

Titanium’s protective oxide forms spontaneously in air, enabling exceptional corrosion resistance. (RSC)

Discovery and Naming of Titanium

Sounds complex? The story of titanium’s discovery is just as intriguing. The titanium chemical element was first identified by William Gregor, who recognized it as a new substance while investigating minerals in England. Later, Martin Heinrich Klaproth confirmed its existence in another mineral and named it after the Titans of Greek mythology—a nod to its impressive strength and resilience (reference). If you’ve ever wondered who discovered titanium, now you know it was a team effort across borders and time.

As you move through this guide, you’ll learn how these fundamental traits—grounded in titanium’s unique spot on the Ti periodic table and its electron configuration—translate into practical decisions about properties, grades, processing, cost, and procurement. Whether you’re an engineer, buyer, or just curious about advanced materials, understanding these basics gives you a smarter start for every titanium-related decision.

Properties That Define Performance

Titanium Density and Strength‑to‑Weight Advantages

When you’re choosing a material for high-performance engineering, the density of titanium is a game-changer. Imagine building an airplane wing or a medical implant: you want something strong, but not heavy. Titanium metal delivers exactly that, with a density that’s about 4.5 grams per cubic centimeter—much less than steel, yet with comparable strength. This unique balance explains why titanium is the backbone of aerospace components, racing car parts, and lightweight prosthetics. The result? Lighter structures, improved fuel efficiency, and easier handling in demanding environments.

| Property | Summary |

|---|---|

| Density | Low (4.5 g/cm³; lighter than steel, heavier than aluminum) |

| Melting Point | High (about 1668°C; enables high-temperature service) |

| Hardness | Moderate to high (varies with alloy and treatment) |

| Corrosion Behavior | Exceptional resistance due to stable oxide film |

| Typical Color | Silvery grey-white (may appear darker after processing) |

- Lighter structures for aerospace, medical, and automotive applications

- Fuel savings and increased payload thanks to low density

- Reduced maintenance costs due to corrosion resistance

- Reliable performance in harsh marine and chemical environments

Titanium Melting Point and Temperature Limits

Ever wondered why titanium shows up in jet engines and exhaust systems? The answer lies in the melting point of titanium, which is approximately 1668°C. This high titanium metal melting point allows it to maintain strength at temperatures where aluminum or even some steels would soften or deform. That’s why it’s a top pick for parts exposed to intense heat—think turbine blades, spacecraft, or performance car engines. Titanium’s ability to handle thermal extremes also means longer component life and fewer failures in service.

Surface Oxide, Color, and Corrosion Resistance

Here’s something you might not notice at first glance: titanium’s famous corrosion resistance is all about its surface. As soon as titanium metal is exposed to air or moisture, it instantly forms a thin, invisible layer of titanium dioxide (TiO2). This passive oxide film is chemically stable and self-healing—if scratched or damaged, it repairs itself as long as oxygen is present (Total Materia). That’s why titanium thrives in seawater, medical implants, and chemical processing plants where other metals would corrode or fail.

Titanium’s oxide film is self-healing and highly protective, underpinning its legendary corrosion resistance.

You’ll notice that the titanium color is typically a silvery grey-white, but processing or alloying can create subtle variations. And if you’re curious—is titanium magnetic?—the answer is no; titanium is non-magnetic, which is important for sensitive electronic or medical applications.

How Alloying Changes Titanium’s Response

Sounds complex? Here’s a practical breakdown. Titanium alloys fall into three main categories: alpha, beta, and alpha-beta. Alpha alloys are tough and resist creep at high temperatures, beta alloys are more formable and weldable, and alpha-beta alloys (like Ti-6Al-4V) offer a balance of strength and ductility (Wikipedia). Alloying elements like aluminum, vanadium, or molybdenum tune properties such as hardness, corrosion resistance, and workability—so you can match the material to the job, whether it’s a hip implant or a submarine propeller shaft.

Understanding these core properties sets the stage for smart grade selection, where you’ll see how to match a titanium alloy to your specific environment, load, and performance needs.

Grade Selection Made Practical

How to Choose Between CP‑Ti and Ti‑6Al‑4V

When you start narrowing down your options for titanium metal grades, the choice often comes down to what matters most: corrosion resistance, strength, formability, or cost. Sounds complex? It doesn’t have to be. Let’s break it down with two of the most widely used grades—commercially pure titanium (CP-Ti, often Grade 2) and the popular alloy Ti‑6Al‑4V (Grade 5).

Pure titanium (CP-Ti) shines in environments where corrosion resistance and ease of fabrication are top priorities. You’ll find it in chemical processing, marine piping, and medical devices—places where the metal’s ability to resist attack from saltwater or harsh chemicals is non-negotiable. On the other hand, titanium alloy Ti‑6Al‑4V delivers superior titanium metal strength and fatigue resistance, making it the go-to for aerospace, automotive, and high-performance medical implants. The trade-off? Ti‑6Al‑4V is tougher to machine and weld, and it comes at a higher cost.

| Use Case | Recommended Grades | Rationale | Fabrication Notes |

|---|---|---|---|

| Marine/chemical processing | CP-Ti (Grade 2) | Excellent corrosion resistance, good ductility | Easy to form and weld; moderate strength |

| Aerospace structural parts | Ti‑6Al‑4V (Grade 5) | High strength-to-weight, fatigue resistance | Challenging to machine; requires specialized tooling |

| Medical implants | CP-Ti (Grade 2), Ti‑6Al‑4V (Grade 5) | Biocompatibility, tailored strength | Grade 2 for corrosion; Grade 5 for load-bearing |

| High-temperature applications | Near-alpha or alpha-beta alloys | Thermal stability, creep resistance | May require advanced forming; costlier |

| Cost-driven, low-stress projects | CP-Ti (Grades 1-4) | Lower cost, easy fabrication | Not for high-load or high-temp service |

Matching Grades to Environments and Loads

Imagine you’re specifying piping for a desalination plant—constant exposure to saltwater, moderate pressure, and a need for reliability. Here, CP-Ti (especially Grade 2) is ideal for its titanium metal properties: outstanding corrosion resistance and formability. But if you’re designing a jet engine component, where high stress, vibration, and elevated temperatures are the norm, Ti‑6Al‑4V’s superior strength and fatigue life make it the smarter choice—even though it’s harder to machine and weld.

Other environments, such as chemical processing with highly reactive media, may require specialty grades like Grade 7 (for added palladium and enhanced corrosion resistance) or Grade 23 (for medical implants needing extra fracture toughness). The right titanium alloy depends on balancing the demands of your application with the specific strengths and weaknesses of each grade.

- Operating temperature (ambient, high, or cryogenic?)

- Exposure media (saltwater, acids, body fluids?)

- Cyclic or impact loads (fatigue a concern?)

- Required surface finish or post-processing

- Regulatory or industry standards (medical, aerospace, etc.)

- Fabrication method (welding, machining, forming?)

- Budget constraints and life-cycle cost targets

Making Trade‑offs Among Strength, Cost, and Fabrication

Here’s where the real-world decision-making happens. Choosing a titanium alloy is about more than just picking the strongest or most corrosion-resistant option. You’ll need to weigh:

- Strength vs. workability: Alloys like Ti‑6Al‑4V give you high titanium metal strength but are tougher to machine and weld, which can drive up manufacturing costs and lead times.

- Corrosion resistance vs. cost: Pure titanium grades are generally more affordable and excel in corrosive environments, but may not meet demanding strength requirements.

- Temperature performance: Near-alpha and alpha-beta alloys offer better high-temperature stability, but they’re usually more expensive and harder to process.

So, how do you make the right call? Start by gathering your project constraints (see the checklist above), then use a decision table like the one here to match your needs to the right titanium metal grades. Don’t forget to validate manufacturability—sometimes the best material on paper creates headaches on the shop floor.

Select the lowest‑cost grade that satisfies environment and load, then validate manufacturability.

Ready to take the next step? The following section will walk you through how titanium goes from raw ore to finished mill products, so you can see how grade selection influences everything from availability to lead time.

How Titanium Metal Is Made

From Ilmenite and Rutile to Titanium Sponge

Ever wondered how titanium metal transforms from a mineral buried in the earth to the high-performance material used in aircraft, medical implants, or chemical plants? The journey is both intricate and fascinating, involving a series of specialized steps that turn raw titanium ore into finished mill products. Let’s break down the process so you can see exactly where value and potential bottlenecks arise along the supply chain.

-

Mining of Ilmenite and Rutile

It all starts with extracting ilmenite (FeTiO3) and rutile (TiO2)—the two primary minerals where titanium is naturally found. Ilmenite is typically mined from beach sands using dredging and earthmoving equipment, while rutile is often extracted from hard rock deposits through drilling and blasting. -

Ore Beneficiation

After mining, the ore undergoes beneficiation to concentrate the titanium-bearing minerals. Ilmenite is purified using magnetic and gravity separation, while rutile, already high in titanium content, requires less processing. -

Chlorination to Produce Titanium Tetrachloride

The concentrated ore is then chlorinated at high temperatures (typically above 900°C). Chlorine gas reacts with the titanium dioxide to create titanium tetrachloride (TiCl4), a volatile liquid that can be further purified. -

Reduction via the Kroll Process

Next, the purified TiCl4 is reduced in a reactor with magnesium or sodium at temperatures above 1,000°C, yielding porous, high-purity titanium sponge and magnesium chloride as a byproduct. -

Purification and Melting

The titanium sponge is removed, cleaned, and often further purified by vacuum arc remelting (VAR) or electron beam cold hearth remelting. This step is critical for applications needing ultra-high purity, such as aerospace or medical devices (Kyocera SGS Tool). -

Alloying and Ingot Formation

The purified sponge (sometimes mixed with alloying elements) is melted and cast into ingots, which are the starting point for all mill products. -

Primary Fabrication: Forging, Rolling, and Extrusion

Ingots are hot-worked into blooms, billets, or slabs. These are then forged, rolled, or extruded into intermediate forms. -

Secondary Fabrication: Mill Products

Finally, the material is processed into finished forms—plate, sheet, bar, tube, and wire—ready for machining or final assembly.

Melting Routes and Ingot to Mill Products

Imagine you’re holding a piece of raw titanium metal sponge. To turn it into something useful, it must be melted—often more than once—to ensure purity and consistency. The most common melting route is vacuum arc remelting (VAR), which provides precise control over chemistry and removes impurities. In some cases, electron beam cold hearth remelting is used, especially for aerospace alloys, to further reduce inclusions and improve cleanliness. The resulting ingots are then hot-worked and rolled into the familiar mill products you see in engineering catalogs.

| Step | Inputs | Outputs | Typical QA | Lead-time Drivers |

|---|---|---|---|---|

| Mining | Ilmenite/rutile ore, energy | Ore concentrate | Grade, impurity checks | Ore quality, logistics |

| Beneficiation | Ore concentrate | Purified Ti minerals | Purity, yield | Separation efficiency |

| Chlorination | Ti minerals, Cl2, heat | TiCl4 | Volatility, purity | Reactor throughput |

| Kroll Reduction | TiCl4, Mg/Na, inert gas | Titanium sponge | Sponge purity, structure | Batch processing time |

| PURIFICATION/Melting | Sponge, alloying elements | Ingot | Composition, inclusion checks | Melting capacity, QA |

| Primary Fabrication | Ingot | Billet, slab, bloom | Dimensional, surface checks | Forge/roll press capacity |

| Mill Product Processing | Billet, slab, bloom | Plate, sheet, bar, tube | Final inspection, testing | Rolling schedule, inspection |

Where Capacity Bottlenecks Typically Occur

Sounds like a smooth flow? Not quite. Each step in the titanium supply chain can introduce its own bottlenecks—places where delays, quality issues, or capacity constraints can ripple downstream and impact delivery times or costs. Here’s what you should watch for:

- Ore Supply: While titanium is abundant, reliance on imported ore and long shipping routes can make the system vulnerable to disruptions, especially in times of geopolitical tension (National Academies Press).

- Sponge Production: Outdated equipment, small batch sizes, and labor-intensive removal of sponge from reactors can slow throughput. High-purity requirements for aerospace and medical grades add extra steps and time.

- Melting and Alloying: Preparing and melting sponge into ingots is time-consuming, especially when triple melting is required for premium grades. Limited furnace capacity and the need for skilled operators can also create bottlenecks.

- Primary and Secondary Fabrication: Inadequate forging, rolling, or extrusion capacity, as well as the need for extensive inspection and surface conditioning, can extend lead times for mill products like plate, sheet, and tube.

- Custom-Job-Shop Nature: The titanium industry often operates as a custom job shop, with frequent starts and stops, in-process checks, and cross-plant transportation—all of which can add to delays and inventory costs.

Sponge quality and melting practice set downstream defect rates; invest in front-end quality.

Understanding where bottlenecks occur and how each step adds value is crucial when evaluating raw titanium metal supply chains. This insight helps you anticipate lead times, plan for volatility, and make smarter procurement decisions. Next up, we’ll walk through practical tips for machining and fabricating titanium, so you can turn those mill products into finished parts with confidence.

Fabrication Playbook for Machining and Welding Titanium

Machining Titanium Without Burning Tools

When you approach machining titanium, it’s easy to underestimate how different it feels compared to steel or aluminum. Imagine the frustration: tools wearing out fast, chips sticking, or even a sudden flash of heat. Why? The answer lies in the titanium metal composition—its low thermal conductivity means heat stays at the cutting edge, while its high strength and tendency to work harden demand careful process control.

Here’s a practical checklist for machinists, whether you’re working with titanium sheet metal or machining a complex aerospace part:

- Tool Selection: Use sharp, rigid carbide or advanced coated tools (AlTiN or similar) to handle heat and resist galling.

- Feeds and Speeds: Run at lower RPM but higher feed per tooth to reduce heat; avoid dwelling or slow passes.

- Coolant: Apply high-pressure, flood coolant directly at the cutting zone to flush chips and control temperature.

- Chip Control: Keep chips clear—built-up edge is common, so ensure good evacuation to prevent re-cutting.

- Workholding: Secure the part rigidly; titanium flexes more than steel, so minimize vibration and deflection.

- Fire Safety: Fine chips and dust are flammable—clean up regularly and keep extinguishers rated for metal fires nearby.

Picture machining a titanium tube for a medical device: by following these do’s and don’ts, you’ll extend tool life, get cleaner finishes, and maintain tight tolerances—even on thin-walled or flexible parts.

Welding Practices for Defect-Free Joints

When it comes to welding, titanium rewards diligence and punishes shortcuts. The most common question isn’t just about technique, but about cleanliness and shielding. If you’re acting as a titanium welder—especially on critical parts like titanium tube or pressure vessels—here’s what matters most:

- Clean all surfaces meticulously—use lint-free gloves, acetone (never chlorine-based cleaners), and dedicated tools to avoid contamination.

- Grind or file back the oxide layer at least 1 inch from the joint, then wipe again before welding.

- Ensure a tight fit-up and use an inert gas (100% argon) for both shielding and back-purging. Trailing shields and gas lenses are essential for full coverage.

- Match filler metal to base alloy, unless your procedure specifies otherwise for ductility or strength.

- Monitor weld color closely: silver, straw, or light brown indicate a sound weld, while blue, green, gray, or white mean contamination—cut out and redo if you see these.

In fact, titanium is what color after welding? Acceptable welds should show a silvery to straw hue. Anything darker signals oxygen contamination and loss of corrosion resistance.

| Process Issue | Likely Cause | Corrective Action |

|---|---|---|

| Lack of Fusion | Poor joint prep, low heat input | Clean thoroughly, check fit-up, adjust parameters |

| Contamination (blue/gray/white weld) | Insufficient shielding, air leaks, dirty tools | Improve gas coverage, check for leaks, reclean surfaces |

| Discoloration (beyond straw) | Overheating, slow travel, trailing shield failure | Increase travel speed, check trailing shield, reduce heat input |

- Clean

- Fixture

- Purge (backside with argon)

- Shield (trailing shield and gas lens)

- Verify (weld color and appearance)

Always reference AWS D10.6 or your certified welding procedure for specific acceptance criteria and filler selection.

Forming, Stress Relief, and Dimensional Control

Working with titanium isn’t just about cutting and joining—it’s also about shaping. Whether you’re forming titanium sheet metal for aerospace skins or bending a titanium tube for medical use, here’s what you need to know (ASM Handbook):

- Forming Windows: Titanium can be cold formed, but expect more springback than with steel. For tight bends or complex shapes, use hot forming (typically 650–815°C).

- Notch Sensitivity: Avoid sharp corners and nicks—titanium is prone to cracking at stress concentrators, especially in cold forming.

- Stress Relief: After forming, perform a stress-relief heat treatment (typically 480–650°C for CP-Ti and Ti-6Al-4V) to restore ductility and dimensional stability.

- Inspection: Use visual and dye penetrant methods to check for cracks, surface defects, or weld contamination. Surface color is a useful cue—again, titanium is what color? Acceptable parts should be silvery-grey, not blue or white.

"Weld color is the most reliable visual indicator of titanium weld quality—silver to straw is acceptable, while blue or white signals contamination and compromised properties."

By following these fabrication fundamentals—whether you’re machining, welding, or forming—you’ll unlock the full performance potential of titanium in every application. Up next, we’ll explore how precision CNC machining brings out the best in titanium, from rapid prototyping to high-complexity production.

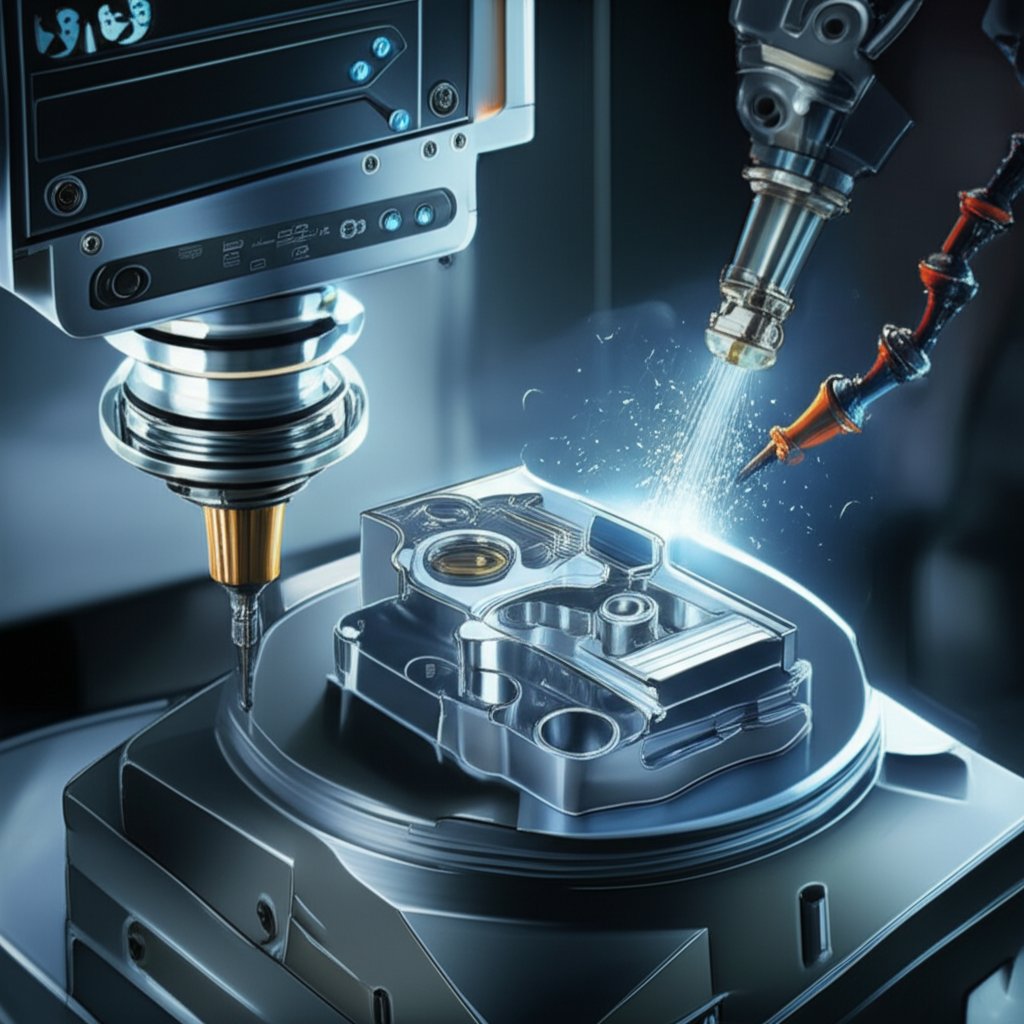

Precision CNC Pathways for Titanium Parts

When Titanium Parts Benefit from 5‑Axis CNC

Ever tried to machine a complex aerospace bracket or a patient-specific medical implant from titanium and hit a wall with part distortion or endless setups? That’s when precision CNC—especially 5‑axis machining—becomes a game-changer. Titanium’s unique properties (high strength, low thermal conductivity, and tendency to work harden) demand more than just basic milling. You’ll notice that intricate geometries, undercuts, or multi-face features are far easier to achieve with 4- or 5-axis workflows, which minimize repositioning and help maintain tight dimensional accuracy.

But here’s the catch: not every shop has the right equipment or expertise. Outsourcing to a specialist with advanced CNC capabilities often makes sense when tolerances are tight, part complexity is high, or you need consistent quality across batches. The impact on titanium material cost is real—while outsourcing can sometimes add to the upfront price, it often reduces risk, scrap, and costly rework in the long run.

| Provider | Capabilities | Certifications | Tolerances/Lead Times | Best For |

|---|---|---|---|---|

| XTJ CNC Machining Services | 4 & 5-axis, high-complexity titanium, full DFM support | ISO 9001, IATF 16949 | ±0.005mm; lead times from 3 days | Prototypes, production, ultra-tight specs |

| In-House | 2/3-axis, limited titanium experience | Varies | ±0.02mm typical; longer for complex parts | Simple shapes, low volumes, standard specs |

| Generalist Supplier | 3/4-axis, moderate complexity, mixed materials | Some ISO | ±0.01mm; standard lead times | Mid-complexity, moderate specs |

If your part requires advanced geometry, ultra-tight tolerances, or rapid turnaround, working with a specialist like XTJ can streamline the process and help keep your titanium material cost predictable, especially for high-value applications.

Design for Manufacturability in Titanium

Sounds complex? It doesn’t have to be. Design for manufacturability (DFM) is about making smart choices up front, so your titanium parts are easier and more cost-effective to produce. Titanium’s characteristics—strength, springback, and heat sensitivity—mean that even small design tweaks can make a big difference in machining success and final part quality.

- Use consistent wall thickness to avoid distortion and uneven cooling.

- Apply generous fillets and radii at internal corners to reduce stress and tool wear.

- Minimize deep pockets and thin ribs—these increase machining time and risk of vibration.

- Design clamping features or tabs for stable workholding throughout multi-axis operations.

- Specify realistic tolerances—tighter than necessary specs can drive up both machining time and titanium material cost.

- Include clear surface finish requirements; titanium responds well to polishing, bead blasting, and anodizing for both function and aesthetics.

Collaborate early with your machining partner—sharing CAD models, annotated drawings, and discussing GD&T (Geometric Dimensioning and Tolerancing) upfront can uncover manufacturability issues before they become expensive problems. This is especially valuable when you’re working with advanced suppliers who provide rapid DFM feedback as part of the quoting process.

Building a Reliable Inspection Plan

Imagine you’ve invested in a batch of titanium parts for a critical application—how do you ensure every piece meets spec? Inspection planning is essential, given titanium’s sensitivity to heat-induced distortion and its tendency to spring back after forming.

- Define key datums and inspection points on your drawings for CMM (coordinate measuring machine) verification.

- Specify surface finish and flatness requirements, especially for sealing or mating surfaces.

- Plan for in-process checks to catch issues like tool wear or part movement early.

- Request full inspection reports with your parts, including material certifications and dimensional results.

For high-value titanium material, these steps help ensure you’re getting the performance you paid for, without surprises at assembly or in the field.

By focusing on smart DFM, leveraging the strengths of advanced CNC partners, and building a robust inspection plan, you’ll maximize the value of titanium’s properties—strength, corrosion resistance, and biocompatibility—while keeping titanium material cost and lead times under control. Next, we’ll dive into how to model lifecycle costs and ROI for titanium compared to other engineering materials, so you can make even smarter decisions for your next project.

Lifecycle Cost and ROI Made Actionable

Lifecycle Cost Model Structure

When you’re faced with the question, “How much does titanium cost compared to other metals?” it’s tempting to focus on sticker price alone. But savvy decision-makers know that the price of titanium per pound or even the titanium price per gram only tells part of the story. The real value of titanium emerges when you consider its entire lifecycle—from purchase to installation, operation, maintenance, and eventual recycling. That’s where a structured lifecycle cost assessment comes in.

- Define the Scope: Clarify what you’re comparing—component, system, or full project. Identify relevant alternatives (e.g., stainless steel, nickel alloys, aluminum).

- Collect Material and Processing Quotes: Gather current cost of titanium per pound and competing materials from RFQs or reputable market databases. Include machining, forming, and finishing costs.

- Model Weight and Performance Impacts: Calculate how titanium’s lower density and higher strength affect total weight, fuel consumption, or payload. For aerospace, this might mean fuel savings; for medical, longer implant life.

- Estimate Maintenance and Service Intervals: Factor in how often parts need inspection, repair, or replacement. Titanium’s corrosion resistance often means fewer shutdowns and lower maintenance spend (Patsnap Eureka).

- Compute End-of-Life Value: Consider salvage or recycling credits. Both titanium and stainless steel have established recycling markets, but recovery rates and infrastructure may differ.

- Run Sensitivity Analysis: Adjust key inputs (material price, service life, maintenance frequency) to see how your ROI shifts. This helps you understand risk and avoid over-committing to a single scenario.

| Cost Category | Titanium | Alternative A | Alternative B |

|---|---|---|---|

| Material Cost (e.g., cost of titanium per pound) |

|||

| Manufacturing & Processing | |||

| Finishing/Coating | |||

| Logistics & Installation | |||

| Maintenance | |||

| Service Life (Years) | |||

| End-of-Life/Salvage | |||

| Total Lifecycle Cost |

Tip: Fill in this table with your actual supplier quotes and project data for the most accurate results.

How Weight and Durability Change the Economics

Imagine you’re designing an offshore component or a medical implant. The titanium price per pound might seem high at first glance, but titanium’s low density means you use less material for the same strength. In aerospace, that translates directly to fuel savings. In chemical processing or marine environments, titanium’s superior corrosion resistance means less downtime and fewer replacements—sometimes extending service intervals by 30–40% compared to stainless steel.

Durability isn’t just about fewer repairs—it can mean avoiding costly shutdowns, reducing labor, and even meeting stricter sustainability requirements. When you factor in these performance benefits, the initial titanium price per gram becomes just one variable in a much larger equation.

Sensitivity Analysis That Actually Helps Decisions

Sounds complex? Let’s make it simple. Sensitivity analysis is about asking, “What if?” What if the cost of titanium per pound drops due to a new supplier, or if your maintenance schedule can be pushed out by a year thanks to titanium’s longevity? By adjusting these variables, you can see which factors have the biggest impact on your total cost of ownership—and where the real value lies.

- Test different material prices (e.g., titanium price per pound vs. current steel or nickel prices).

- Model longer or shorter service intervals based on real-world data.

- Explore how recycling credits or end-of-life values affect your ROI.

Using this approach helps you avoid common pitfalls like underestimating maintenance or overvaluing initial price. It also gives you a clear framework for discussing trade-offs with stakeholders, suppliers, or finance teams.

Lifecycle cost beats unit price when performance extends service life. (Internal methodology)

Ready to act? The next section will equip you with procurement language and supplier checklists to turn your lifecycle analysis into smarter buying decisions—ensuring you get the right titanium, at the right cost, with the right guarantees.

Standards and Procurement Checklists You Can Use

Specifying Material and Product Forms the Right Way

When you’re ready to buy titanium—whether it’s bar, plate, sheet, tube, or forgings—precision in your specifications is the first step to a successful purchase. Sounds complex? Not if you know what to ask for. By aligning your request with recognized standards and clear requirements, you’ll reduce risk, avoid costly mistakes, and ensure you’re truly getting the titanium metal for sale that fits your application.

| Product Form | Typical Spec Families | Notes |

|---|---|---|

| Bar/Rod | ASTM B348 | Covers chemical, mechanical, and testing requirements for bars and rods |

| Plate/Sheet/Foil | ASTM B265 | Defines composition, mechanical properties, and corrosion resistance for flat-rolled products |

| Forgings | ASTM B381 | Specifies requirements for forged titanium and alloys, including strength and inspection |

| Medical Implants | ASTM F136 | Biocompatibility and mechanical property standards for medical-grade alloys |

| Welding Materials | ASTM B862 | Requirements for titanium alloy welding rods, including corrosion and mechanical performance |

Referencing the correct standards in your RFQ or purchase order helps suppliers quickly match your needs and ensures compliance with industry best practices.

Supplier Vetting and Quality Documentation

Finding where to buy titanium metal goes beyond just searching for the lowest price. Imagine you’ve found a source offering titanium for sale—how do you know they’re reputable? Here’s a practical supplier checklist to help you evaluate and de-risk your procurement:

- Certifications: ISO 9001 (quality management), AS9100 (aerospace), ISO 13485 (medical devices) as relevant

- Past Performance: Proven experience supplying titanium for your industry/application

- NDT (Non-Destructive Testing) Capabilities: Ability to provide ultrasonic, radiographic, or dye penetrant inspection as required

- Lot Traceability: Full material traceability with mill test reports and certificates of compliance

- Raw Material Sources: Transparent sourcing, preferably from qualified mills

- Inspection Equipment: Modern, calibrated equipment for dimensional and property verification

- Customer Service: Responsive technical support and timely communication

Quality documentation is non-negotiable. Always request heat certifications, mechanical and chemical test reports, and clear traceability back to the original mill lot. This is especially critical for aerospace, medical, and critical industrial applications.

RFQ Checklist for Machined Titanium Parts

Ready to send out a request for quote and wondering where can I buy titanium metal with confidence? A clear, detailed RFQ not only attracts better suppliers but also ensures you get accurate, apples-to-apples quotes. Here’s a copy-and-paste-ready checklist for your next titanium RFQ:

- Complete drawing files (PDF, CAD, or both)

- Material grade and condition (e.g., ASTM B348 Grade 5, annealed)

- Product form and dimensions (bar, plate, tube, etc.)

- Required tolerances and GD&T (Geometric Dimensioning & Tolerancing)

- Surface finish requirements (e.g., Ra value, anodizing, bead blast)

- Non-destructive testing (NDT) or inspection methods (ultrasonic, dye penetrant, etc.)

- Material certifications and traceability documentation

- Heat treatment or special processing requirements

- Delivery schedule and location

- Packaging and labeling instructions

Tip: Attach any relevant standards or acceptance criteria to your RFQ to avoid ambiguity. The more specific you are, the easier it is for suppliers to quote accurately and for you to compare offers side by side.

"A well-structured RFQ and supplier checklist are your best defense against costly surprises when sourcing titanium for sale."

By following these standards and checklists, you’ll be prepared to identify where to buy titanium and navigate the procurement process with confidence—whether you’re searching for titanium metal for sale for the first time or refining your approach for critical projects. Next, we’ll cover safety and inspection essentials to ensure your titanium investment performs as expected from delivery through final use.

Safety and Quality Control Essentials for Titanium Fabrication

Shop Safety for Titanium Machining and Grinding

When you’re working with titanium metal, safety isn’t just a checklist—it's the foundation of every successful project. Imagine a busy shop: titanium chips flying, grinding wheels spinning, and the occasional spark. Sounds routine? With titanium, small lapses can quickly escalate. Fine chips and dust pose a real fire risk, and improper handling can lead to expensive material loss or even injury. Here’s how to keep your workspace—and your investment—safe:

- Personal Protective Equipment (PPE): Always wear safety glasses or goggles to protect your eyes from flying debris. Nitrile or leather gloves shield your hands from sharp edges and prevent direct contact with fine particles.

- Respiratory Protection: Use appropriate respirators when machining or grinding titanium, especially if dust is generated. Titanium dust can be hazardous if inhaled.

- Fire Prevention: Keep your work area clean. Fine titanium dust or chips can ignite easily—especially around heat sources. Have Class D (dry powder) fire extinguishers on hand and remove dust regularly.

- Coolant and Heat Control: Use high-quality cutting fluids to dissipate heat and reduce friction. Overheating not only wears tools but also increases fire risk.

- Safe Storage: Store titanium in a dry, clean, well-ventilated area—away from moisture, heat, and corrosive chemicals. This prevents accidental oxidation and keeps your titanium looking its silvery best (if you’re wondering does titanium tarnish, it’s highly resistant but not immune if neglected).

Proper training is vital. Make sure everyone handling titanium understands the unique risks and best practices—regular safety briefings can make a world of difference.

NDT and Inspection Without Over-Spending

How do you know your titanium part is free from hidden cracks or inclusions? Non-destructive testing (NDT) is your answer. But with so many methods, which one should you choose? Here’s a scannable pros/cons breakdown for the most common NDT techniques used on titanium metal:

-

Visual Inspection

- Pros: Fast, inexpensive, detects surface defects and discoloration (e.g., after welding—what color is titanium? Acceptable welds are silvery to straw; blue or white means contamination).

- Cons: Can’t detect internal flaws; operator skill-dependent.

-

Dye Penetrant Testing

- Pros: Excellent for surface cracks; simple process; high sensitivity to small flaws.

- Cons: Limited to surface-breaking defects; can’t spot subsurface issues.

-

Radiographic Testing (X-ray/Gamma Ray)

- Pros: Reveals internal cracks, porosity, and inclusions; produces a permanent record.

- Cons: Requires specialized equipment and safety protocols; higher cost.

-

Ultrasonic Testing

- Pros: Highly sensitive to internal defects; quick and cost-effective for production runs.

- Cons: Needs skilled operators; may miss flaws with irregular shapes or orientations.

Choosing the right NDT method depends on your part’s application and criticality. For high-value or safety-critical parts, combine methods for the best coverage.

Repair and Rework Strategies That Preserve Integrity

Even with the best planning, defects can appear. The key is knowing how to spot, prevent, and repair them—without compromising your titanium’s performance or blowing your budget on rework. Here’s a practical table to guide your approach:

| Defect | Likely Root Cause | Prevention/Repair |

|---|---|---|

| Weld contamination/discoloration | Insufficient shielding, dirty surfaces | Improve cleaning, use more inert gas, cut out and re-weld if blue/white color appears |

| Surface roughness | Dull tools, incorrect machining parameters | Use sharp tools, adjust speed/feed, polish or re-machine as needed |

| Cracks/porosity | Improper heat input, impurities, fast cooling | Control welding/casting parameters, inspect with NDT, repair by grinding/welding if allowed |

| Distortion | Residual stress, uneven cooling | Apply stress relief heat treatment, adjust fixturing, slow cooling |

| Galling | Poor lubrication, excessive load | Use appropriate lubricants, reduce load, polish surfaces |

Routine inspection and preventive maintenance are your best tools for minimizing scrap price of titanium and maximizing the value of every pound. Remember, titanium per lb is a premium investment—catching defects early saves both money and reputation.

Cleanliness and shielding are non‑negotiable for weld quality.

To wrap up, a disciplined approach to safety, inspection, and defect management keeps your titanium projects on track—whether you’re worried about the price per pound of titanium or simply want to ensure your parts never fail in the field. Next, we’ll summarize actionable steps and trusted resources to help you make smarter titanium decisions, from concept through production and beyond.

Actionable Recommendations and Trusted Resources for Titanium Metal Decisions

When to Choose Titanium Over Alternatives

Wondering if titanium is the right move for your next project? Start by asking: Is titanium expensive compared to alternatives, and what do I really gain? Titanium’s higher upfront cost—often a sticking point for buyers—stems from its complex extraction and processing. But if you need a material that’s strong, light, corrosion-resistant, or biocompatible, the investment can pay off in performance and lifecycle value. Imagine you’re weighing the cost of titanium vs steel for a chemical processing plant: steel may win on initial price, but titanium’s resistance to aggressive media can slash maintenance and replacement costs over years of service.

Choose titanium when:

- Corrosion or chemical attack is a critical risk (marine, chemical, medical environments)

- Weight reduction translates to real savings or performance (aerospace, sports, implants)

- Long service life and reduced maintenance offset higher initial price

- Biocompatibility or non-magnetic properties are essential

Still debating why is titanium so expensive? Much of the answer lies in its energy-intensive refining and machining requirements. But, as you’ve seen, the right application often justifies the cost.

From Design to Purchase Order with Fewer Surprises

Ready to move from concept to production without costly missteps? Here’s a clear, step-by-step action list to guide your titanium journey—from initial idea to finished part—while keeping a close eye on how much is a pound of titanium and total project value.

- Define the Application: Clarify what is titanium metal used for in your project—load, environment, regulatory needs.

- Select the Grade: Choose the grade that matches your corrosion, strength, and formability needs. Don’t over-specify; higher grades mean higher cost.

- Build a Lifecycle Cost Model: Compare how much is titanium per pound with alternatives, but factor in weight savings, service life, and maintenance. This is where titanium’s real value emerges.

- Finalize Design for Manufacturability (DFM): Collaborate with experienced fabricators early to optimize wall thickness, tolerances, and surface finish. This step helps avoid unnecessary machining costs and delays.

- Issue Detailed RFQs: Use clear specs, reference industry standards, and include all quality, inspection, and documentation requirements.

- Vet Suppliers: Prioritize partners with proven titanium expertise, relevant certifications, and robust quality control.

- Plan Inspection and Quality Assurance: Define acceptance criteria, NDT methods, and reporting expectations upfront.

- Monitor Cost Drivers: Track not just the price per pound, but also scrap rates, lead times, and total delivered cost.

"The true worth of titanium is revealed when lifecycle costs, not just purchase price, drive your decision."

Trusted Partners for Complex Titanium Work

Success with titanium often hinges on choosing the right manufacturing partner—especially for high-precision or high-value parts. Here’s a shortlist to get you started:

- XTJ CNC Machining Services – Specialists in 4- and 5-axis titanium machining, ISO 9001 & IATF 16949 certified, ultra-tight tolerances (±0.005mm), and rapid delivery. Ideal for prototypes and production where complexity, speed, and quality matter.

- In-house or local precision machine shops – Best for simple designs, low volumes, or when project control is your top priority.

- Generalist suppliers with titanium experience – Suitable for less complex, higher-volume applications where cost is the main driver.

By following this approach, you’ll answer the key questions—is titanium expensive, how much is titanium worth, and what is titanium metal used for—with data, not guesswork. The result? Smarter sourcing, stronger products, and fewer surprises from design through delivery.

Titanium Metal: Frequently Asked Questions

1. Is titanium a good quality metal?

Titanium is highly valued for its strength, low weight, and exceptional resistance to corrosion. These qualities make it a top choice for aerospace, medical, and industrial applications where reliability and performance are critical. Its biocompatibility and non-magnetic nature further expand its use in medical implants and sensitive electronics.

2. What is titanium mainly used for?

Titanium is widely used in aerospace components, medical implants, chemical processing equipment, and marine applications. Its high strength-to-weight ratio and corrosion resistance make it ideal for demanding environments, while its biocompatibility ensures safe use in the human body. It also appears in sports equipment and high-performance automotive parts.

3. How does titanium compare to steel in terms of cost and performance?

While titanium typically has a higher upfront cost per pound than steel, it offers superior corrosion resistance and a much lower weight for the same strength. Over a product's lifecycle, titanium can provide better value by reducing maintenance, extending service life, and enabling weight savings, especially in aerospace or chemical environments.

4. Where is titanium naturally found and how is it processed?

Titanium occurs naturally in minerals like ilmenite and rutile, often extracted from beach sands or hard rock deposits. The metal is produced through a multi-step process: mining the ore, beneficiation, chlorination to form titanium tetrachloride, reduction to titanium sponge, and then melting and forming into mill products such as sheets, bars, and tubes.

5. What factors should I consider when sourcing titanium metal?

When sourcing titanium, specify the required grade, form, and standards (such as ASTM codes), and verify supplier certifications and traceability. Include detailed RFQ requirements—drawings, tolerances, inspection methods, and documentation. Partnering with experienced CNC specialists can help ensure quality and cost control for complex titanium parts.

-

Posted in

titanium cost, titanium grades, titanium machining, titanium procurement, titanium properties