Brass Plumbing Fittings For PEX, Copper, PVC: Compatibility Solved

What Makes Brass Plumbing Fittings Work So Well?

What are brass plumbing fittings?

Ever wondered why so many professional plumbers and DIYers reach for brass plumbing fittings when tackling water or gas lines? Brass fittings are connectors made from a copper-zinc alloy, designed to join pipes, control flow, or adapt between different sizes and materials. You’ll see them in everything from home water lines to industrial air compressors. Their unique blend of durability and versatility makes them a staple across residential and commercial plumbing systems.

Why brass is a go-to in residential and commercial systems

Imagine installing a water system that needs to last for decades, handle high pressures, and resist corrosion. That’s where brass shines. Thanks to its robust composition, brass plumbing fittings provide:

- Durability: Brass stands up to high pressure and tough environments, making it ideal for both water and gas applications.

- Corrosion resistance: Unlike iron or steel, brass fittings resist rust and many chemicals, ensuring long-term reliability—even in damp or chemically active settings.

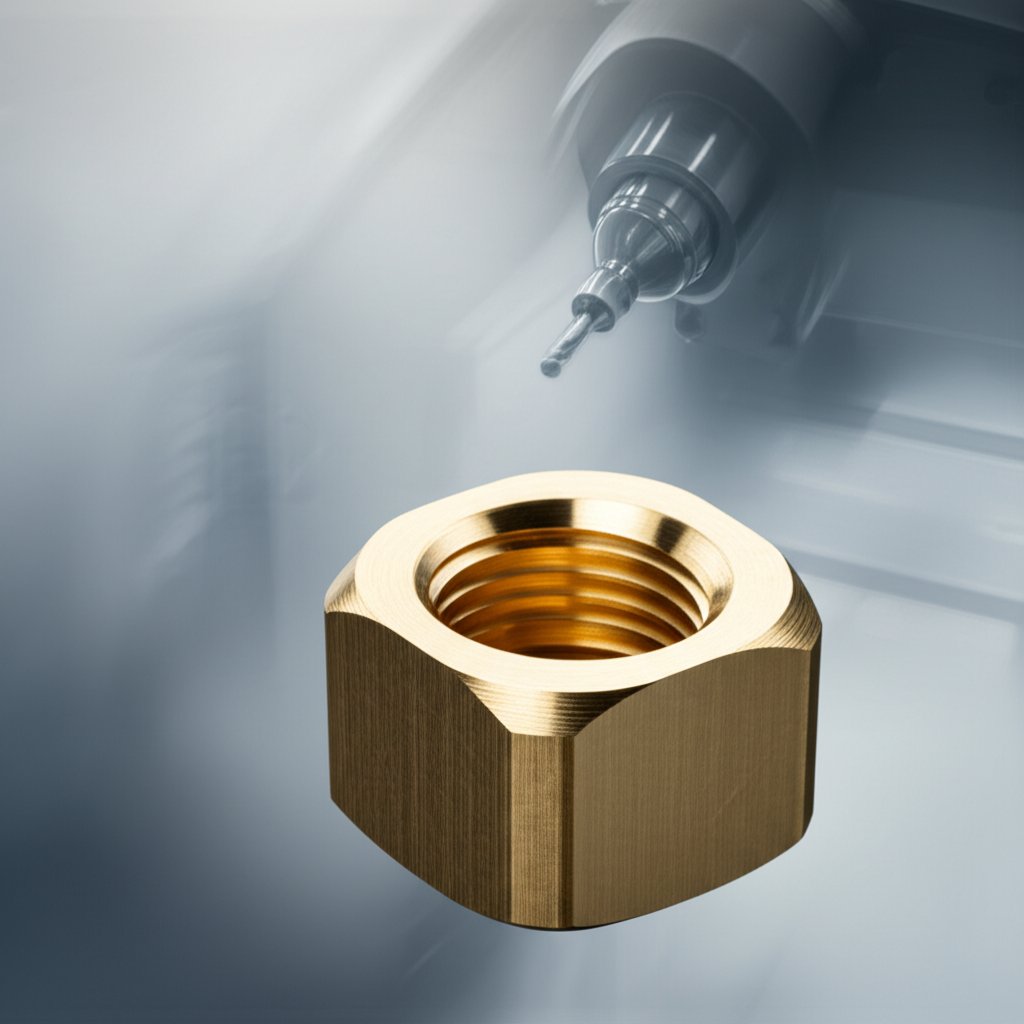

- Machinability: Brass is easy to shape and thread, so manufacturers can create a wide range of fitting types and sizes, from simple couplings to complex adapters.

- Serviceability: Need to swap out a valve or reconfigure a line? Brass fittings are easy to disassemble and reuse, minimizing downtime and repair costs.

- Versatility: Use them for potable water, gas, air, and even some chemical lines—brass water fittings and brass gas pipe fittings are trusted in both homes and industry.

- Aesthetic appeal: Their golden color adds a touch of elegance, especially in exposed installations.

Performance-wise, brass fittings can generally handle a wide temperature range (from well below freezing to hot water conditions) and pressures suitable for most plumbing and HVAC needs. For example, depending on the design and alloy, standard brass fittings are typically available for a temperature range from near freezing point to about 400°F (204°C), and their pressure ratings can range from the common 125 psi (for low-pressure applications) to over 1000 psi (for certain high-pressure applications).

When brass might not be the best choice

Of course, no material is perfect for every job. Brass plumbing fittings do have limitations. If your water supply is highly acidic or contains high levels of chlorine, brass can corrode over time—a process called dezincification. In these cases, plastic or stainless steel fittings may be a safer bet. Similarly, if lead content is a concern (especially in older brass), always choose modern, lead-free certified fittings for potable water lines.

- Not ideal for: Highly acidic or chloride-rich water, some aggressive chemicals, or where local codes prohibit brass.

- Potential for dezincification: Prolonged exposure to certain water chemistries can weaken brass over time.

- Cost: Brass is pricier than plastic alternatives, though its longevity often offsets the initial investment.

Brass plumbing fittings strike a smart balance between cost, longevity, and compatibility—but always match the material to your specific water chemistry and application needs.

How this guide helps you choose wisely

Feeling overwhelmed by endless catalogs and technical jargon? This article is designed to make your decision easier. Here’s what you’ll find as you read on:

- Clear explanations of fitting types and where to use them

- Guidance on brass alloys, lead content, and corrosion resistance

- Thread standards, compatibility with PEX, copper, and PVC

- How to read specs, choose suppliers, and maintain your system

- Visual aids and decision tools to reduce trial and error

Brass fittings compete with copper, stainless steel, and engineered plastics—each with their own strengths and drawbacks. As you move through this guide, keep your system’s dimensions, media (water, air, gas), temperature, and pressure in mind. These factors will shape every decision, from material selection to installation and long-term care.

Ready to dive deeper? Next, we’ll break down the core types of brass fittings and how to match them to your application.

Core Fitting Types and Where To Use Them

Core brass fitting types and functions

Ever walked down a plumbing aisle and wondered why there are so many shapes and sizes of brass pipe fittings? Each type serves a unique role, and knowing when to use them can make your project smoother and more reliable. Let’s break down the most common fittings you’ll encounter and where each one shines:

| Fitting Type | Typical Use-Case | Joining Method | Service Media | Notes |

|---|---|---|---|---|

| Elbows (45°/90°) | Change direction in piping (e.g., around corners in water/gas lines) | Threaded, compression, flare | Water, air, gas | Brass elbow fittings help avoid sharp bends and flow restriction. |

| Tees | Branch off main line (e.g., splitting water supply to multiple fixtures) | Threaded, compression, flare | Water, air, gas | Brass tee fittings create distribution points in loops or branches. |

| Couplings | Join two straight pipe sections | Threaded, compression, push-to-connect | Water, air, gas | Brass couplers are ideal for repairs and extending lines. |

| Unions | Allow easy disassembly for maintenance (e.g., pumps, heaters) | Threaded | Water, air, gas | Brass unions simplify future servicing—no cutting required. |

| Adapters | Transition between pipe sizes/materials (e.g., copper to PEX) | Threaded, compression, flare | Water, air, gas | Great for connecting dissimilar systems or fixtures. |

| Caps | Seal pipe ends (permanent or future expansion) | Threaded, solder, push-fit | Water, air, gas | Protects against debris and leaks. |

| Plugs | Temporarily block pipe ends (maintenance or testing) | Threaded | Water, air, gas | Quick solution for isolation. |

| Bushings | Reduce pipe size in fittings | Threaded | Water, air, gas | Used for step-down transitions. |

| Nipples | Connect two female fittings | Threaded | Water, air, gas | Short lengths of pipe with male threads both ends. |

| Valves | Control flow (on/off or regulate rate) | Threaded, compression | Water, air, gas | Ball, gate, and check valves are common types. |

| Hose/Barb Fittings | Connect flexible hoses (e.g., garden, irrigation) | Barb with clamp, threaded | Water (mainly), air | Brass hose fittings and barbs suit low-pressure, flexible lines. |

Choosing by flow direction and service needs

Sounds complex? It’s easier when you think about what your system needs to do. For example, if you need to split a water line to two bathrooms, a brass tee fitting is your go-to. If you’re installing a water heater and want future maintenance to be easy, brass unions are invaluable. For outdoor irrigation, brass hose fittings or barbed adapters are the most DIY-friendly.

- Use brass elbow fittings to smoothly redirect flow around obstacles or corners.

- Brass couplers are best for extending or repairing straight runs.

- Brass unions simplify equipment servicing—no pipe cutting required.

- Adapters help when joining different pipe materials or sizes (think pipe connector brass or transitioning from copper to PEX).

- Caps and plugs seal lines for future expansion or temporary shutdowns.

- Valves provide control, while bushings and nipples help with size transitions and tight spaces.

Common size ranges and joining methods

You’ll notice brass pipe fittings come in a wide range of sizes—from tiny compression elbows for refrigerator water lines to large threaded brass pipe fittings for industrial systems. The joining method depends on the application:

- Threaded: The most common for general plumbing and gas lines. Use PTFE tape or thread sealant for leak-free joints.

- Compression: Great for copper, plastic, or small-diameter tubing—no soldering needed.

- Flare: Used in refrigeration and fuel lines for a secure, vibration-resistant seal.

- Push-to-connect: Quick, tool-free installation—ideal for temporary or flexible setups.

- Barbed: For hoses and flexible tubing, secured with clamps.

Always check product datasheets for pressure and temperature ratings, especially for critical or high-pressure applications. Not all fittings are rated for every media or condition—using the right type prevents leaks and premature wear.

- Match fitting type to your system’s demands—don’t stretch hose fittings or barbs beyond their rated service.

- Thread integrity and sealing methods matter: PTFE tape for most threads, anaerobic sealants for metal-to-metal, and gaskets for hose connections.

- For potable water, ensure fittings are lead-free and certified safe for drinking water.

Understanding these core fitting types and their best uses sets you up for leak-free, serviceable installations. Next, we’ll explore how the specific brass alloy in your fitting impacts corrosion resistance, lead content, and long-term performance.

Understanding Brass Alloys For Plumbing

Common Brass Alloys for Fittings

When you pick up a brass plumbing pipe fitting, have you ever wondered what’s actually inside that golden connector? The answer matters more than you might think—especially for water quality, corrosion resistance, and long-term reliability. Most brass fittings for water are made from copper and zinc, but the proportions (and any extra elements) can change how the fitting behaves over years of service.

- Yellow Brass: Contains higher zinc (typically 20–37%), giving it a bright yellow tint. It’s easy to machine and commonly used for fittings, but can be more vulnerable to certain types of corrosion.

- Red Brass: Has a higher copper content (around 85%), resulting in a reddish-gold color. Red brass pipe fittings are prized for their natural corrosion resistance and are a top choice for potable water lines and critical plumbing systems.

- DZR (Dezincification Resistant) Brass: Specially formulated to withstand aggressive water chemistries that would otherwise attack standard brass, making it the go-to for installations with soft, acidic, or high-chloride water.

But there’s more to the story—each alloy has trade-offs in machinability, lead content, and resistance to specific failure modes. That’s why you’ll see different alloys recommended for different brass plumbing pipe fittings, depending on where and how they’ll be used.

Dezincification and How to Mitigate It

Imagine a fitting that looks fine on the outside but is slowly turning porous and weak inside. That’s the risk of dezincification—a process where zinc is leached out of brass, leaving behind spongy copper and oxides. This can cause leaks and failures in brass water pipe fittings, especially in areas with soft, acidic, or high-chloride water. Dezincification is most common in yellow brasses with higher zinc content and can be accelerated by high temperatures or aggressive water chemistry (CEP Experts).

To combat this, manufacturers now offer DZR brass fittings. These are engineered with lower zinc content (below 15%) and often include inhibitors like antimony or arsenic to further resist zinc loss. DZR alloys are ideal for ball valves, unions, and other brass plumbing pipe fittings in challenging environments.

| Alloy Type | Machinability | Dezincification Resistance | Lead-Free Status | Typical Use |

|---|---|---|---|---|

| Yellow Brass | High | Low | May contain lead (verify) | General plumbing, gas, air |

| Red Brass | Medium | High | Lead-free options available | Potable water, critical systems |

| DZR Brass | Medium | Very High | Lead-free options available | Hot water, aggressive chemistries |

Lead-Free and Potable Water Compliance

Safety is non-negotiable—especially for drinking water. Modern red brass fittings and DZR designs are usually available in certified lead-free versions. Always check for NSF/ANSI 61 or 372 certification, which signals compliance with strict standards for lead content and water safety. Red brass pipe fittings, with their naturally low lead content and high copper percentage, are especially valued in schools, hospitals, and other sensitive environments.

- For brass fittings for water, always confirm third-party certification and review manufacturer data sheets.

- Lead-free brass plumbing pipe fittings are now widely available, but don’t assume—alloy labels alone don’t guarantee compliance or performance.

- Some DZR and lead-free alloys may be a bit harder to machine, but the trade-off is worth it for corrosion resistance and regulatory safety.

Always match your brass alloy to your water chemistry and local code—don’t rely on color or alloy name alone. Confirm certifications and test results before installation.

In summary, the right alloy keeps your brass plumbing pipe fittings leak-free and safe for years. Before making your final choice, check with local codes and water utility advisories—especially if your system draws from wells or untreated sources. Up next, we’ll show you how to identify thread standards and ensure your fittings integrate smoothly with copper, PEX, PVC, and more.

Threads And System Compatibility Made Easy

NPT Versus BSP Threads: Why Getting It Right Matters

Ever tried screwing two pipes together only to find they just won’t seal? The culprit is often mismatched thread standards. In the world of brass plumbing fittings, thread type is the invisible detail that can make or break your installation. Let’s break down the essentials so you can avoid leaks and wasted time.

| Thread Type | Region/Common Use | Seal Style | Typical Use-Cases | Standard |

|---|---|---|---|---|

| NPT (National Pipe Tapered) | North America, some Asia | Thread sealant (PTFE tape/pipe dope) | General plumbing, gas, air, oil | ASME B1.20.1 |

| BSPP (British Standard Pipe Parallel) | UK, Europe, Australia, Asia | Washer or O-ring | Hydraulics, HVAC, water lines | ISO 228-1 |

| BSPT (British Standard Pipe Tapered) | UK, Europe, Australia, Asia | Thread sealant (PTFE tape/pipe dope) | Gas, water, industrial | ISO 7-1 |

| Metric (Parallel/Tapered) | Europe, Asia, automotive | O-ring, metal-to-metal, or sealant | Hydraulics, compressors, specialty | ISO Metric |

Here’s the key: NPT threads are not compatible with BSP threads—the thread angle, pitch, and taper are different. Always match the thread type to your fitting and piping system, whether you’re working with brass npt fittings, metric brass fittings, or BSP variants.

Joining Brass Fittings to Copper, PEX, PVC, and Stainless Steel

Sounds tricky? It’s actually manageable when you know the right adapters and methods. Here’s how to connect brass plumbing fittings to common piping materials:

- Copper: Use soldered or press adapters to transition from copper pipe to threaded brass. For a secure brass to copper fitting, solder a male or female adapter onto the copper, then thread on the brass npt pipe fitting.

- PEX: Insert fittings are your friend—slide the PEX over a barbed brass insert, then secure it with a crimp or clamp ring. Use threaded adapters to connect to npt brass fittings or other threaded outlets.

- PVC: Solvent-weld a socket adapter to the PVC, then thread a brass male or female fitting into place. Always use PTFE tape or compatible thread sealant when mating pvc brass fittings to avoid leaks.

- Stainless Steel: Use brass npt fittings with stainless adapters, and always include a dielectric union if water is involved. This prevents galvanic corrosion where metals meet.

- Metric Systems: For European or automotive projects, metric brass fittings or adapters bridge the gap between metric pipe and standard brass compressor fittings.

Sealing Strategies That Actually Work

Imagine finishing your install, turning on the water, and seeing a drip form—frustrating, right? The right sealing method depends on your thread type and media:

- NPT/BSPT (Tapered): Always use PTFE tape or pipe dope to fill thread gaps and create a watertight seal. Tapered threads seal by wedging together as you tighten (Adaptall).

- BSPP/Metric Parallel: These threads don’t seal by themselves—rely on a bonded washer or O-ring at the mating face. This is key for many industrial and compressor applications using brass compressor fittings.

- Check Thread Orientation: Male vs. female matters! Verify thread pitch, diameter, and if a gasket or O-ring is required for your connection.

- Sealant Selection: Match the sealant to your media—water, gas, oil, or air—and operating temperature. For potable water, use sealants rated for drinking water lines.

Mixing thread standards—like NPT and BSP—almost always leads to leaks or thread damage. Double-check before you assemble.

In summary, understanding thread standards and sealing approaches is the secret to leak-free, long-lasting brass plumbing fittings. Always verify your thread type, use the correct sealant, and never force mismatched threads. Next, we’ll show you how to read spec sheets and match fittings to your system’s pressure, temperature, and dimensional needs.

Pressure, Temperature, and Dimensional Basics

Reading a Brass Fitting Spec Sheet

Ever stood in front of a shelf full of brass threaded fittings and wondered, “How do I know which one is right for my job?” Choosing the correct fitting isn’t just about matching pipe size—it’s about understanding the numbers behind the product. Let’s break down what you’ll see on a typical spec sheet so you can make confident, leak-free choices.

| Spec Attribute | Typical Value/Description | What It Means for You |

|---|---|---|

| Pressure Class | 125–2210 psi (varies by size/type; see below) | Indicates max safe working pressure. Always check ratings for your exact size and type. |

| Temperature Range | -20°F to 400°F (typical); higher temps reduce pressure ratings | Fittings rated for hot water/steam may lose strength at high temps. Always check derating tables. |

| Media Compatibility | Water, air, gas, some oils | Ensure your application matches the listed compatible fluids. |

| Thread Standard | NPT, BSP, or metric (varies) | Verify thread type for leak-free assembly. Most U.S. fittings use NPT. |

| Dimensional Callouts | Nominal size (e.g., 1/2 inch, 3/4 inch, 1 1/4 inch), ID/OD, wall thickness | Match your pipe’s size and wall to ensure a proper fit. Cross-check with manufacturer drawings for critical installs. |

| Certifications | NSF/ANSI, lead-free, pressure/temperature ratings | Required for potable water or code compliance. |

Pressure and Temperature Frameworks: Matching the Fitting to the Job

When you’re selecting high pressure brass fittings, it’s crucial to understand how pressure and temperature interact. As temperature rises, the maximum allowable pressure drops. For example, a standard 1/2 inch brass pipe fitting (regular wall) is rated for 900 psi at 100°F, but only 790 psi at 300°F. Extra strong (XS) fittings of the same size can handle up to 1760 psi at 100°F, dropping to 1540 psi at 300°F. Here’s a quick look at some common sizes (Engineering Toolbox):

| Nominal Size | Regular Pipe (100°F) | Extra Strong Pipe (100°F) |

|---|---|---|

| 1/8 inch | 370 psi | 1960 psi |

| 1/4 inch | 870 psi | 2210 psi |

| 1/2 inch | 900 psi | 1760 psi |

| 3/4 inch | 810 psi | 1510 psi |

| 1 inch | 630 psi | 1340 psi |

| 1 1/4 inch | 690 psi | 1160 psi |

These numbers show why 1 4 brass pipe fittings and 1 8 brass pipe fittings are often chosen for high-pressure applications, while 3 4 inch brass pipe fittings and 1 1 4 brass pipe fittings meet the needs of larger, lower-pressure lines. Always check the manufacturer’s data for your specific fitting, as wall thickness and construction method can vary.

Dimensional Standards and Tolerancing: Getting the Right Fit

Sounds confusing? It doesn’t have to be. Brass pipe fittings use nominal sizes, which don’t always match the actual measured diameter. For example, a 1 2 inch brass pipe fitting refers to the nominal pipe size, not the exact ID or OD. Threaded brass fittings also rely on thread pitch and taper—NPT threads are tapered for sealing, while some metric or BSP threads are parallel and require washers or O-rings.

To avoid mismatches, always:

- Double-check nominal vs. actual size using a sizing chart or caliper.

- Confirm thread type and pitch—especially if mixing U.S. and international fittings.

- Review manufacturer drawings for critical dimensions, especially for 3 4 brass pipe fittings and 1 1 4 brass pipe fittings in commercial installs.

- Allow for tolerances—some fittings may have minor variations due to machining or casting.

Common Pitfalls When Reading Brass Fitting Specs

- Mixing up nominal and actual sizes—easy to do with 1 2 inch brass pipe fittings or metric equivalents.

- Overlooking thread taper—tapered NPT vs. parallel BSP/metric can cause leaks.

- Ignoring temperature derating—never exceed the listed max pressure at your system’s hottest point.

- Assuming all brass is lead-free—always check certifications for drinking water lines.

Always build in a safety margin and consult local codes or standards before finalizing your selection. A little extra diligence now prevents costly leaks and rework later.

By mastering these basics, you’ll confidently select brass threaded fittings and high pressure brass fittings that match your system’s true needs. Next, we’ll compare brass to other materials so you can make the smartest material choice for your water, air, or gas application.

How To Choose Brass Versus Other Materials

When Brass Is the Smart Default

Ever wondered why brass plumbing fittings seem to show up in so many water, air, and gas systems? Imagine you’re installing a line for potable water, compressed air, or even gas in a residential or light industrial setting. Brass is often the first choice for a reason: it offers a robust balance of durability, reliability, and ease of use. In compressed air systems, for example, brass pneumatic fittings deliver both mechanical strength and resistance to vibration—key for minimizing leaks and maintenance.

- Handles moderate to high pressure and temperature better than most plastics

- Resists corrosion under typical potable water and air conditions

- Easy to install, thread, and service—making future repairs or upgrades simpler

- Well-suited to applications like water distribution, air compressor lines, and gas hookups

Brass pneumatic fittings are especially common in manufacturing and automation where reliability and mechanical strength matter, but the environment isn’t so aggressive that stainless steel is required.

When to Choose Stainless Steel or Plastics

But what if your application involves harsh chemicals, marine environments, or extreme temperatures? That’s where the equation changes. Stainless steel outperforms brass in high-corrosion or high-temperature settings, such as food processing, chemical plants, or outdoor installations exposed to saltwater. Meanwhile, engineered plastics—like acetal, polypropylene, or nylon—shine when chemical compatibility, low weight, or cost are top priorities.

- Stainless Steel: Best for aggressive environments, high pressure, or where hygiene is critical. More expensive, but offers unmatched corrosion resistance and longevity.

- Plastics: Ideal for low- to medium-pressure water, certain chemicals, or where weight and ease of installation are key. Not recommended for high-pressure or hot water/gas applications.

- Copper: Still a favorite for soldered potable water lines and where thermal conductivity is needed, but less versatile for threaded or high-pressure connections.

| Material | Corrosion Resistance | Temp. Tolerance | Mechanical Strength | Ease of Install | Repairability | Recyclability |

|---|---|---|---|---|---|---|

| Brass | Good (except in high-chloride/acidic) | Moderate-High | High | Easy (threaded, compression) | Easy (disassemble/reuse) | Excellent |

| Stainless Steel | Excellent | Very High | Very High | Moderate (harder to machine) | Moderate (may require special tools) | Excellent |

| Engineered Plastics | Excellent (chemicals), Good (water) | Low-Moderate | Moderate | Very Easy (push-to-connect) | Easy (replace, not repair) | Good |

| Copper | Good (water), Poor (acids) | High | Moderate | Moderate (soldering required) | Easy (resolder/replace) | Excellent |

Cost, Lifecycle, and Maintenance Trade-Offs

Imagine you’re weighing the upfront price of brass vs steel air fittings, or comparing brass to galvanized pipe for an air or water line. Brass costs more than most plastics but less than stainless steel. However, its total cost of ownership is often lower due to fewer leaks, less frequent replacement, and simple repairs. Stainless steel, while costly, may be the only safe option for highly corrosive or regulated environments, ultimately saving on downtime and catastrophic failures.

- Brass: Best for general potable water, light industrial air, and gas lines—especially where future disassembly or expansion is likely.

- Stainless Steel: Choose for marine, food, or chemical plants, or anywhere corrosion and hygiene are non-negotiable.

- Plastics: Use for low-pressure, non-critical water or chemical lines, and where cost or weight are limiting factors.

- Copper: Go-to for soldered domestic water lines and heat-exchange applications.

For mixed-metal systems, such as brass to galvanized pipe, always use dielectric unions or adapters to prevent galvanic corrosion. When combining copper and brass fittings, compatibility is generally good, but always verify with local code and system requirements.

Total cost of ownership isn’t just about the sticker price—consider service life, maintenance, and the risk of leaks or failures before you choose a fitting material.

As you narrow down your options, always factor in local code requirements, water or air chemistry, and how easy it will be to access and service your fittings down the road. Next up, we’ll walk you through a supplier checklist to ensure you’re getting quality, compliant brass plumbing fittings for your project.

Supplier Verification and Procurement Checklist for Brass Plumbing Fittings

Documentation You Should Always Request

When you’re sourcing brass plumbing fittings—whether for a small repair or a major project—the risks of leaks, compliance issues, or costly rework can be high if you cut corners on supplier checks. Sounds overwhelming? It doesn’t have to be. Imagine you’re preparing to order from brass pipe fittings manufacturers or a new brass plumbing fittings supplier. Here’s a practical, step-by-step procurement checklist to safeguard your project and budget.

-

Confirm Material and Alloy Callouts

Ask for the specific brass alloy used (e.g., DZR, red brass) and ensure it matches your application’s needs. This is vital for corrosion resistance and regulatory compliance. -

Request Certificates

For potable water or regulated applications, require NSF/ANSI 61 or 372 certificates, certificates of conformance, and detailed material test reports. These documents verify safety, composition, and performance. -

Verify Thread Standards and Dimensional Drawings

Ensure the fittings match your required thread type (NPT, BSP, metric) and dimensions. Ask for technical drawings to avoid mismatches during installation. -

Review Surface Finish and Cleanliness

Inspect for smooth surfaces, free from pits, burrs, or other defects. A quality finish not only looks professional but also ensures leak-free joints and long-term reliability. -

Align Pressure/Temperature Ratings

Check that the pressure and temperature ratings meet or exceed your system’s requirements. Don’t assume all brass fittings are created equal—ratings can vary by manufacturer and design. -

Check Manufacturer Quality Certifications

Look for ISO 9001, ISO 14001, or other relevant certifications. These signal robust quality systems and process control at the brass fittings manufacturer’s facility. -

Evaluate Lead Times, MOQs, and Packaging

Clarify minimum order quantities, standard lead times, and packaging options. Reliable brass pipe fittings suppliers should offer clear, consistent timelines and protective packaging to prevent transit damage. -

Define Warranty and Returns Policy

Ask for warranty terms and return procedures. Strong warranties reflect the supplier’s confidence in their product and protect you from early failures or defects.

Verifying Quality and Conformity

Imagine you receive a shipment and discover mismatched threads or visible flaws. Avoid surprises by using this quick evaluation guide for any brass plumbing fittings supplier:

- Responsiveness: Fast, clear communication signals a professional operation.

- Traceability: Can the supplier trace each batch to raw material and test reports?

- Documentation Quality: Are certificates, drawings, and inspection records complete and easy to understand?

- Reputation: Check customer reviews and case studies for real-world performance.

- Product Range: Do they stock a wide selection of sizes and types, or just a few basics?

When your order arrives, conduct a visual and dimensional check—measure threads, inspect finishes, and verify markings against your order sheet. If tolerances or inspection plans are provided, use them as your acceptance criteria.

Logistics, Pricing, and After-Sales Support

It’s tempting to focus only on the unit price, but savvy buyers know to look at the big picture. Imagine comparing two brass pipe fittings suppliers: one offers a lower price, but the other provides faster lead times, better documentation, and a stronger warranty. Which is the better deal?

Always compare quotes by total landed cost—including shipping, duties, and any required testing. Consider the risks of downtime or rework if you cut corners on quality. For large or ongoing projects, ask about buffer inventory, batch traceability, and options for remote audits or factory visits.

Choosing a brass plumbing fittings supplier is about more than price—prioritize quality, documentation, and support to ensure long-term system reliability.

By following this checklist and working with reputable brass pipe fittings manufacturers, you’ll reduce risk, ensure compliance, and protect your investment. Now that you know how to vet your suppliers, the next step is keeping your system running smoothly—let’s dive into maintenance and troubleshooting best practices.

Inspection, Maintenance, and Troubleshooting for Brass Plumbing Fittings

What to Inspect and How Often

When you rely on brass plumbing fittings for water lines, air compressors, or any critical system, staying ahead of leaks and failures starts with a solid maintenance routine. Sounds complicated? It’s not—just a matter of knowing what to look for and when. Imagine you’re doing a routine check: what should you focus on?

- Visual Corrosion and Discoloration: Look for green or bluish stains, especially near joints—these signal oxidation or early corrosion.

- Seepage at Threads: Check all brass threaded pipe fittings for dampness, mineral deposits, or crusty residue—these are classic signs of slow leaks.

- Stress Cracking Near Bends: Pay attention to areas where the pipe or fitting changes direction or is under mechanical stress. Tiny cracks here can quickly become big problems.

- Mechanical Damage: Inspect for dents, scratches, or deformed threads, particularly if fittings have been recently tightened or moved.

- Evidence of Dezincification: Watch for a powdery or pinkish surface—this means zinc is leaching out, weakening the fitting.

- Plugs and Caps: Don’t ignore pipe plugs brass or end caps—they need the same scrutiny as mainline brass connections.

How often should you do these checks? A good rule of thumb is at least once a year for most residential systems, but more frequent inspections may be needed for high-pressure, high-use, or outdoor installations.

Recognizing Early Signs of Failure

Imagine spotting a tiny drip before it turns into a flood. Early detection is all about knowing the warning signs. During your inspection of brass fittings for water lines or brass air compressor fittings, look for:

- Dampness or Water Droplets: Even a slight touch of moisture around a fitting can indicate a leak.

- Mineral Deposits: White or green crust around fittings often means water is escaping and evaporating, leaving minerals behind.

- Thread Wear or Deformation: If the threads on your brass threaded pipe fittings look worn, flattened, or stripped, sealing may be compromised.

- Unusual Noises: In air systems, a faint hissing may point to leaks in brass air compressor fittings.

- Reduced System Performance: Lower water pressure or air flow can signal hidden leaks or partial blockages.

Proactively replacing fittings that show any of these symptoms is key to avoiding bigger failures down the road.

Repair Versus Replace: Making the Right Call

When you discover an issue, how do you decide whether to repair or replace? Here’s a straightforward troubleshooting workflow for brass plumbing fittings:

- Confirm Media and Pressure: Make sure the system is operating within the recommended pressure and temperature range for your fittings.

- Retorque as Needed: Gently tighten brass connections using the manufacturer’s torque specifications. Avoid overtightening, which can crack or strip threads.

- Reseal Threads: If a leak persists, disassemble the fitting, inspect for damage, and reapply the appropriate sealant (PTFE tape for water, pipe dope for air/gas). Always wrap tape in the direction of the threads for best results.

- Replace Compromised Parts: If you see cracks, severe corrosion, or signs of dezincification, replace the fitting—temporary fixes won’t restore long-term integrity.

- Escalate if Recurrent: If leaks or failures keep returning, consider whether system design, vibration, or incompatible metals are causing the issue. Sometimes, a redesign or material upgrade is the only lasting solution.

Most leaks in brass fittings stem from mismatched threads or improper sealing—not from the fitting itself. Always check thread compatibility and follow sealant instructions closely.

Best Practices for Longevity and Documentation

- Gentle Cleaning: Use mild soap and a soft cloth to keep fittings free of dirt and debris—never use abrasive cleaners.

- Protective Coatings: In humid or corrosive environments, consider applying a clear protective coat to exposed fittings.

- Moisture Control: Insulate or shield fittings where condensation or water exposure is likely.

- Thread Gauges and Tools: Use thread gauges to verify fit, and always use tools designed for brass to avoid damaging threads or deforming fittings.

- Maintenance Log: Keep a record of inspections, repairs, and replacements. This documentation is invaluable for future audits, warranty claims, or troubleshooting recurring issues.

Remember, the service interval for your brass fittings should reflect system criticality and environmental exposure. For example, brass fittings for water lines in a residential basement may need less frequent checks than brass air compressor fittings in a busy workshop.

By sticking to these inspection, maintenance, and troubleshooting practices, you’ll extend the life of your brass plumbing fittings and minimize the risk of costly leaks or downtime. Next, we’ll explore when off-the-shelf solutions fall short—and how custom machining can deliver the perfect fit for your unique application.

Custom Brass Fittings With Precision CNC Machining

When to Custom Machine Brass Fittings

Ever tried to connect two pipes only to find that no off-the-shelf brass adapter fits your space or thread requirements? Or maybe you’re building a prototype that demands a unique seal or a metric-to-imperial transition. That’s when custom brass fittings—like custom brass fittings or specialty brass tube fittings—become essential.

- Unique thread transitions: When your system mixes NPT, BSP, or metric threads, standard parts just won’t cut it. Custom machining lets you specify exact combinations for leak-free results.

- Tight envelope constraints: Sometimes, space is so limited that only a made-to-measure fitting will fit—think lab setups or compact machinery where every millimeter counts.

- Specialty seals and geometries: Instrumentation, high-pressure, or hazardous media lines often need custom grooves or faces for O-rings, or special sealing surfaces that aren’t available in catalogs.

- Metric-to-imperial conversions: International projects or equipment retrofits often require custom metric pipe fittings brass to bridge different standards.

- Ultra-tight tolerances: High-pressure, gas, or vacuum systems may require tolerances tighter than standard options—sometimes down to ±0.005mm for critical brass tube fitting assemblies.

In short, if your project demands more than what’s on the shelf, custom machining is the answer. But which process is right for you?

Comparing Custom Manufacturing Options for Brass Fittings

| Process | Lead Time | Achievable Tolerance | Surface Finish | Cost Profile | Best For |

|---|---|---|---|---|---|

| CNC Machining (XTJ) | 3–7 days (rapid), scalable to mass production | ±0.005mm (ultra-tight) | Excellent (as-machined or post-finished) | Competitive for prototype and production; no MOQ | Complex geometries, leak-critical features, prototype-to-production runs |

| Forging + Machining | 2–6 weeks (includes tooling) | ±0.05mm (good for most plumbing) | Good (may need secondary finishing) | Cost-effective for large batches | High-volume, standard shapes with moderate complexity |

| Additive (3D Printing) + Machining | 1–3 weeks (prototype); longer for production | ±0.1mm (machined faces tighter) | Varies (often needs machining for sealing) | Best for rapid prototypes or complex internal features | Low-volume, highly complex or internal channels |

You’ll notice that CNC machining—especially from a provider with 4/5-axis capability, ISO 9001 & IATF 16949 certifications, and rapid lead times—delivers the tightest tolerances and flexibility for both one-off and production runs. For example, XTJ’s CNC Machining Services can turn around high-precision custom brass fittings in as little as 3 days, with tolerances tight enough for even demanding gas or instrumentation work. This is especially valuable when you need metric brass pipe fittings or specialty brass adapter fittings that must integrate perfectly with existing systems.

Design for Manufacturability: Tips for Reliable Custom Brass Fittings

Designing a custom brass fitting? Here’s how to ensure your part works flawlessly—and is easy to manufacture:

- Material Choice: Select DZR or lead-free brass for potable water or aggressive environments, balancing machinability with corrosion resistance.

- Thread Standards: Clearly specify thread type, pitch, and class—especially for metric, NPT, or BSP combinations. Ambiguity here can cause leaks or rework.

- Geometric Dimensioning & Tolerancing (GD&T): Define sealing faces, O-ring grooves, and critical diameters with appropriate tolerances. For leak-critical surfaces, ±0.005mm may be required.

- Surface Finish: Indicate if a polished, plated, or passivated finish is needed—especially for visible or corrosion-prone parts. Specify if post-processing like electroless nickel or powder coating is required.

- Cleaning & Packaging: For potable service or sensitive media, request ultrasonic cleaning and sealed packaging to prevent contamination.

- Documentation: Provide detailed CAD files and, if possible, request a Design for Manufacturability (DFM) review to spot potential issues early.

These tips help ensure your brass adapter or brass push to connect fittings are not only easy to install but also reliable over the system’s lifetime.

Quality Controls That Matter

Quality is non-negotiable when your system’s integrity depends on a single fitting. Imagine a custom brass tube fitting in a high-pressure line—one missed spec can mean leaks or costly downtime. Here’s what to look for in a machining partner:

- Certifications: ISO 9001 & IATF 16949 signal robust process control and traceability.

- Inspection Protocols: Look for in-process and final inspection of all critical dimensions, especially threads and sealing faces.

- Material Traceability: Ensure each batch of metric pipe fittings brass or custom parts can be traced to certified raw material.

- Batch Testing: For high-risk applications, request pressure, leak, or functional testing on a sample basis.

- Documentation: Require inspection reports and, for regulated applications, certificates of compliance or test results.

Custom brass fittings bridge the gap when standard parts won’t do—precision machining and tight quality controls ensure your system stays leak-free and compliant, even in the toughest applications.

Ready to move from idea to installation? With the right design details and a trusted CNC partner, you can transform even the most complex requirements into reliable, high-performance brass plumbing solutions.

Frequently Asked Questions about Brass Plumbing Fittings

1. What are the disadvantages of brass fittings?

Brass fittings can be affected by dezincification in acidic or high-chloride water, may contain lead if not certified lead-free, and are generally more expensive than plastic alternatives. They're also softer than steel, making them susceptible to wear in high-vibration environments. For potable water, always verify lead-free certification.

2. Do plumbers still use brass pipes and fittings?

Yes, brass fittings remain a popular choice among plumbers for both residential and commercial systems. Their durability, corrosion resistance, and ease of installation make them suitable for water, gas, and air lines. However, plumbers may opt for alternatives like copper, stainless steel, or plastics in environments where brass is less ideal.

3. How do I choose the right brass plumbing fitting for my project?

Select brass fittings based on application (water, gas, air), compatibility with your pipe material (PEX, copper, PVC), pressure and temperature requirements, and local code compliance. Check for lead-free and DZR certifications if used for drinking water, and match thread standards (NPT, BSP, metric) to prevent leaks.

4. Are brass plumbing fittings safe for potable water systems?

Modern brass fittings labeled as lead-free and certified to NSF/ANSI 61 or 372 are considered safe for potable water. Always verify certifications and choose DZR or red brass for enhanced corrosion resistance in aggressive water conditions.

5. When should I consider custom-machined brass fittings?

Custom brass fittings are ideal for unique thread transitions, tight spaces, metric-to-imperial conversions, or when precise tolerances are needed for leak-critical or high-pressure applications. CNC machining services like XTJ can produce complex, certified fittings tailored to your specifications.

-

Posted in

brass plumbing fittings, custom brass fittings, lead-free brass, pipe fitting types, plumbing compatibility