What Is Brass? Copper–Zinc Alloy Basics, Types, And Specs

What Is Brass and Why Does It Matter?

What Is Brass Definition and Core Concept

Ever picked up a shiny gold-colored doorknob or admired the warm glow of a trumpet? Chances are, you’ve encountered brass—a metal that’s everywhere, but often misunderstood. So, what is brass? In the simplest terms, brass is an engineered copper and zinc alloy. It’s not a pure element like copper or zinc, but a blend of these two metals in varying proportions. This unique combination gives brass a set of properties that make it stand out in the world of metals.

Brass is a copper–zinc alloy prized for its workability, corrosion resistance, and distinctive golden color.

What Metals Are in Brass and Why It Matters

At its core, brass material is made by mixing copper with zinc. Adjusting the zinc content changes the alloy’s characteristics. For example, a higher zinc percentage typically results in a lighter, more yellow color, while lower zinc leans toward a deeper, reddish gold. Most brasses contain between 60–70% copper and 30–40% zinc, but small additions of other elements—like lead, tin, or aluminum—can further enhance properties like machinability or corrosion resistance.

Why does this brass composition matter? Because it allows manufacturers to tailor brass for specific jobs. Need something that’s easy to machine into a complex shape? There’s a brass for that. Looking for a material that resists corrosion in plumbing or marine environments? Brass can be adjusted for that, too. This flexibility is what makes brass such a popular choice across industries.

Common Forms and Everyday Uses of Brass

Imagine walking through a hardware store or browsing an online supplier. You’ll see brass available in a variety of forms:

- Bar – Used for machining parts like gears, fasteners, and valves

- Brass sheet metal – Ideal for decorative panels, architectural trim, and stamped components

- Brass pipe and tube – Common in plumbing, musical instruments, and structural fittings

- Castings – Used in hardware, marine fittings, and ornate fixtures

Brass shows up in places you might not expect: plumbing fittings, musical instruments, fasteners, valves, locks, light fixtures, and even jewelry. Its distinct color and corrosion resistance make it a favorite for both practical and decorative uses (Britannica).

- Machinability: Easy to cut, drill, and shape for precision parts

- Corrosion Behavior: Withstands water and many chemicals, making it ideal for plumbing and marine applications

- Visual Appearance: Ranges from warm gold to pale yellow, often used for decorative effect

- Cost Positioning: More affordable than gold, and often less expensive than pure copper or bronze

Brass vs. Bronze and Other Metals: Clearing Up the Confusion

It’s easy to mix up brass with bronze or even copper. Here’s the quick rundown: brass is a copper zinc alloy; bronze is mostly copper with tin (and sometimes other elements). Brass is typically chosen for its ease of machining, bright color, and corrosion resistance—while bronze is valued for its wear resistance and strength in marine environments.

When to Choose Brass Over Other Metals

Wondering what is brass made of and when it’s the right pick? If you need a metal that’s easy to work with, resists corrosion, and offers a beautiful finish, brass is a solid choice. It’s especially popular for parts that require intricate machining, decorative appeal, or durability in wet environments.

In later sections, we’ll dive deeper into brass’s physical properties, the different types and grades available, and how to select the right brass for your project. Whether you’re comparing brass sheet metal for architectural work or choosing brass pipe for plumbing, understanding the basics of brass composition will help you make informed, confident decisions.

How Brass Composition Drives Performance

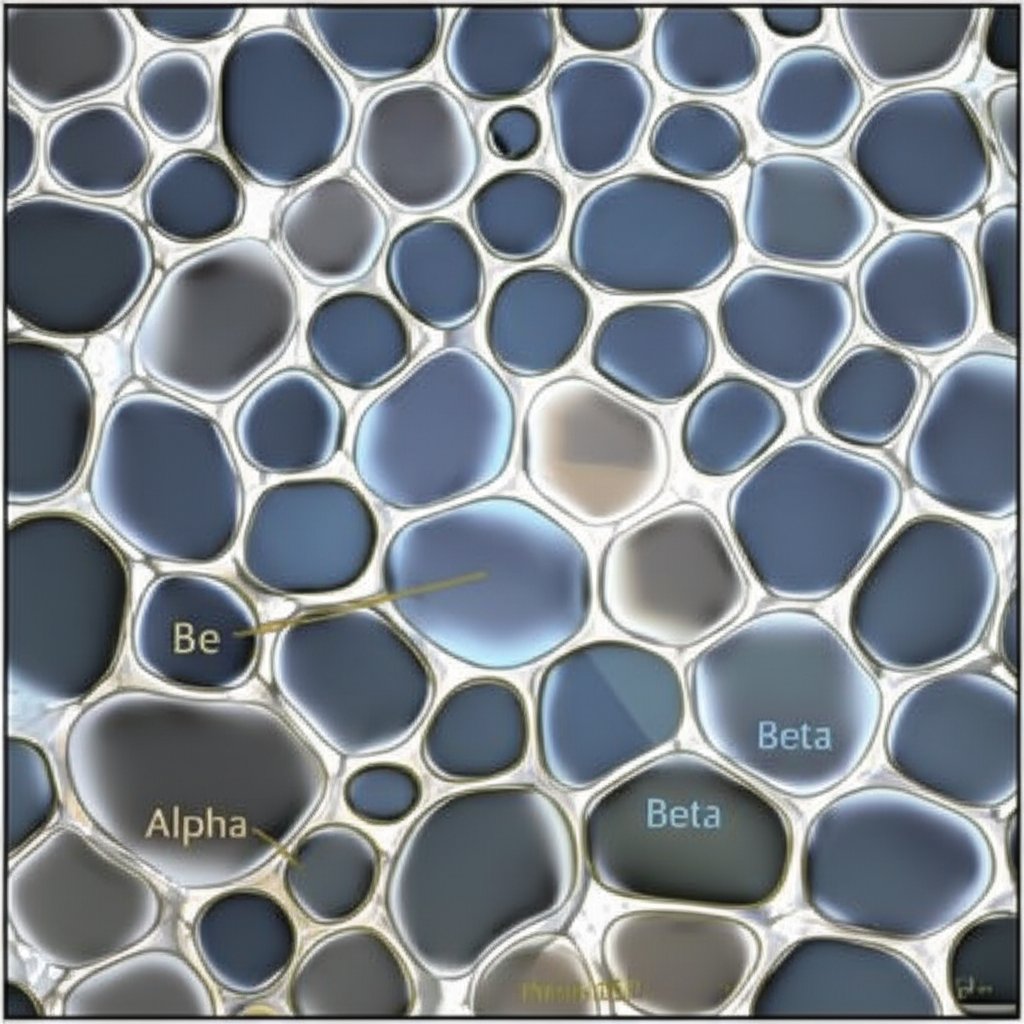

Cu–Zn Basics: Understanding Alpha and Beta Brasses

When you’re choosing a brass for your project, you’re really deciding how much copper and zinc you want in your alloy. But why does this matter? The answer lies in the microstructure—the way copper and zinc atoms arrange themselves—which determines how the metal behaves in real-world applications.

Brass is an alloy, not a pure metal. The simplest brass metal composition is just copper and zinc, but the ratio makes all the difference. At lower zinc levels (up to about 35%), you get alpha brass, which is a single-phase structure. This means the copper and zinc are thoroughly mixed, resulting in a soft, ductile, and easily workable material. Alpha brasses are ideal for cold forming processes like deep drawing, bending, and stamping—imagine making cartridge cases or intricate decorative panels (Copper Development Association).

As you increase the zinc content (typically 35–39%), a second phase called beta starts to appear. This creates a two-phase structure known as alpha-beta brass or duplex brass. The beta phase is harder and stronger, but less ductile at room temperature. These brasses are best hot-worked—think hot forging or extrusion for plumbing fittings or complex hardware—because they’re easier to shape when heated.

| Composition Band | Phase Structure | Typical Processing Route | Common Uses |

|---|---|---|---|

| Up to ~35% Zn | Alpha (single-phase) | Cold forming, drawing, stamping | Cartridge brass, jewelry, radiator cores |

| ~35–39% Zn | Alpha + Beta (duplex) | Hot working (forging, extrusion) | Plumbing fittings, valves, hardware |

| >39% Zn | Predominantly Beta | Hot working, casting | Muntz metal, marine applications |

How Minor Elements Change Workability and Corrosion

Sounds complex? Here’s where it gets even more interesting. Small amounts of other elements are often added to brass to fine-tune its properties. For example, lead is commonly included in alpha-beta brasses to improve machinability. The lead forms tiny globules that break up chips during machining, making it easier to cut precise threads or holes.

Tin, aluminum, silicon, and arsenic are also added for specific reasons. Tin, for example, boosts corrosion resistance in admiralty and naval brasses—perfect for marine or plumbing environments. Silicon can increase strength and enhance hot-working performance, while arsenic or antimony can help prevent a failure mode called dezincification, where zinc is selectively leached out of the alloy in aggressive waters (Canadian Conservation Institute).

- Lead: Improves machinability (especially in alpha-beta brasses)

- Tin: Increases resistance to corrosion (admiralty/naval brasses)

- Aluminum/Silicon: Enhances strength and hot-workability

- Arsenic/Antimony: Prevents dezincification in plumbing brasses

From Microstructure to Performance: What to Expect

So, how does all this science translate to real-world choices? If you need a brass that’s easy to bend or deep-draw—like for musical instruments or cartridge cases—alpha brass is your go-to. If your part needs to be strong and will be hot-forged or machined, an alpha-beta brass with a bit of lead is a smart pick. For plumbing or marine fittings, look for brasses with tin, arsenic, or other additives to resist corrosion and dezincification.

- Alpha brass: Best for cold forming, high ductility, moderate strength

- Alpha-beta brass: Higher strength, good for hot working, excellent machinability

- Minor alloying elements: Fine-tune corrosion resistance, machinability, and hot/cold workability

Understanding what is brass composed of at the microscopic level helps you predict how it will behave—whether you’re shaping, machining, or installing it in a tough environment. Next, we’ll explore how these metallurgical choices affect physical properties like hardness, melting point, and corrosion resistance, helping you pick the right brass for your specific needs.

Properties That Drive Performance

Brass Melting Behavior and Thermal Considerations

Ever wondered what happens when you heat brass to its limits? The melting point of brass isn’t a single number—it shifts depending on the exact mix of copper, zinc, and any extra elements. For most common brass alloys, the melting range for most common brass alloys is typically between 880°C and 960°C (1620°F and 1760°F), but can change based on grain size, impurities, and even how the brass is made. For example, larger grains or more impurities may lower the melting temperature, while smaller grains or certain alloying additions can push it higher. Even the casting method and heating rate can play a role. This means that if you’re working with brass—whether casting, forging, or machining—knowing the precise grade and its melting range helps you avoid defects like warping or incomplete fills.

Density, Strength, and Hardness Ranges

Why does brass density matter? Imagine you’re designing a part that must be strong but not too heavy—brass offers a sweet spot. The density of brass typically ranges from 8.4 to 8.7 g/cm³, depending on the copper-zinc ratio and any extra elements like tin or aluminum. Yellow brass, which contains more zinc, sits near 8.4 g/cm³, while red brass—with higher copper—can be as dense as 8.7 g/cm³. Naval brass, used in marine settings, is about 8.41 g/cm³. These differences matter for everything from plumbing valves to ship hardware: higher density often means more strength and vibration resistance, while lighter brasses are easier to handle and install.

Brass’s hardness and strength also shift with composition and processing. Finer grain structures (created by rolling or forging) typically result in harder, denser, and stronger brass. Adding tin or aluminum can boost hardness for wear resistance, while more zinc makes brass easier to shape but a bit softer. This flexibility lets engineers and builders pick the perfect brass for the job—whether it’s a decorative panel or a heavy-duty propeller shaft.

| Alloy Family | Density (g/cm³) | Melting Point (°C) | Notable Traits |

|---|---|---|---|

| Yellow Brass (C26800/C27000) | ~8.4 | ~900 | Bright gold color, easy to shape, good for heat exchangers |

| Red Brass | ~8.7 | ~900 | Heavier, reddish tint, excellent corrosion resistance |

| Naval Brass | ~8.41 | ~900 | Added tin for marine strength, resists saltwater corrosion |

Magnetism, Corrosion, and Surface Appearance

Is brass magnetic? For most practical purposes, brass is not magnetic. The copper-zinc structure doesn’t allow for magnetic attraction, which is why you’ll never see a magnet stick to a brass doorknob or fitting. This non-magnetic property is helpful in applications where stray magnetic fields must be avoided, such as in electronics or sensitive instruments.

Will brass rust? Unlike iron or steel, brass does not rust. Instead, it forms a thin, protective patina that resists further corrosion. This makes it ideal for plumbing, marine, and outdoor decorative uses. However, in certain aggressive environments—like warm, high-chloride water—brass can suffer from a process called dezincification, where zinc slowly leaches out, weakening the part. Regular inspection and choosing the right brass alloy can help prevent this.

What about brass color? The color spectrum runs from warm, golden yellow (high zinc) to a deeper, reddish hue (high copper). Surface treatments like polishing, brushing, or lacquering can further enhance or protect the finish. Over time and with exposure, brass may tarnish, developing a duller or even greenish patina—especially outdoors or in humid settings. Some people love this aged look, while others prefer to restore the shine with regular cleaning.

Brass is generally non-magnetic and does not rust, but it can tarnish.

Understanding these core physical and mechanical properties helps you choose the right brass for your needs—whether you want a gleaming decorative finish or a rugged, corrosion-resistant component. Next, we’ll compare brass to copper and bronze, so you can spot the differences and pick the best metal for your project.

Brass Versus Copper and Bronze Made Simple

Brass vs Copper vs Bronze: What Sets Them Apart?

Ever wondered why some metals look gold, others reddish, and some a muted brown? Or maybe you’ve picked up a heavy candlestick and asked, “Is this copper, brass, or bronze?” Understanding the difference between copper and brass—and how bronze fits in—can help you make better choices for everything from hardware to collectibles to marine fittings.

| Metal | What Is It Made Of? | Color | Conductivity | Strength & Hardness | Corrosion Resistance | Machinability | Common Uses |

|---|---|---|---|---|---|---|---|

| Copper | Pure copper element (Cu) | Reddish-brown | Very high (excellent electrical & thermal) | Soft, ductile | Excellent in most environments (forms green patina outdoors) | Good (but softer than brass/bronze) | Electrical wiring, cookware, roofing, bus bars |

| Brass | Copper + Zinc (copper–zinc alloy) | Pale yellow to deep gold, sometimes reddish | High (lower than copper) | Medium (stronger than copper, softer than most bronzes) | Good (can tarnish, resists rust, but may dezincify in harsh water) | Excellent (easy to cut, drill, shape) | Musical instruments, plumbing fittings, fasteners, decorative hardware |

| Bronze | Copper + Tin (plus other elements) (bronze made of what metal: mainly copper & tin) |

Dull gold, brownish, sometimes with reddish tint | Moderate (lower than copper & brass) | High (harder & stronger than copper or brass) | Excellent, especially in marine/harsh conditions | Good (often cast or machined for wear parts) | Bearings, bushings, marine hardware, sculptures, bells |

Color, Conductivity, and Corrosion in Practice

Let’s break it down with real-life scenarios. If you see a reddish-brown wire or pot, it’s probably copper—pure, highly conductive, and prized for electrical work. Brass stands out with its bright gold or yellow tone, making it a favorite for doorknobs, musical instruments, and decorative trim. Bronze, on the other hand, has a muted, dull gold or brown color, often with subtle rings or a heavier feel. This makes it ideal for statues, bells, and marine applications, where durability is key.

On performance, copper leads in conductivity and is easy to shape, but it’s softer and can dent easily. Brass offers a balance—good conductivity, better strength, and excellent machinability, which is why it’s used for intricate fittings and fasteners. Bronze is the toughest of the three, with superior wear resistance and marine corrosion protection, thanks to its tin content and other alloying elements. That’s why when you ask, what is bronze made out of, the answer is more than just copper and tin—it’s a recipe for long life in tough conditions.

Identification Tips Without Lab Equipment

Imagine you’re sorting through a box of old hardware or picking out a vintage lamp. How can you tell if it’s copper, brass, or bronze—without fancy tools?

- Color Cues: Copper = reddish-brown; Brass = yellow to gold; Bronze = dull gold or brownish

- Weight/Density: Bronze is usually heavier than brass of the same size; copper is also quite dense

- Patina: Copper turns green (verdigris); brass darkens or gets a muted sheen; bronze develops brown or green layers

- Magnet Test: None of these are magnetic—if a magnet sticks, it’s likely not pure copper, brass, or bronze

- Sound: Tap the item—bronze rings lower and more resonant, brass is higher-pitched, copper is softer

- Surface Details: Bronze may show faint casting rings or seams; brass and copper are often smoother

Quick Workshop Checklist: How to Identify Red Metals

- Check color under good light—compare with known samples if possible

- Feel the weight—bronze is typically heavier than brass

- Look for patina or aging—green means copper, brown/green means bronze, dark gold means brass

- Try a magnet—no attraction means it’s likely one of the red metals

- Listen for sound—tap gently and note the pitch

- Inspect for casting marks—bronze often has visible seams or rings

Understanding these differences isn’t just about trivia—it’s about choosing the right metal for your job. Next, we’ll dive deeper into the specific grades and standards of brass, so you can confidently select the best alloy for your next project.

Types of Brass Grades and Standards

Common Brass Grades and Where They Shine

When you start comparing types of brass, you’ll notice each grade is engineered for a specific purpose—whether that’s forming, machining, or withstanding harsh environments. But what are the metals in brass, and how do different grades stack up? Let’s break down the most widely used brass alloys and their typical roles:

| Grade Name | UNS/CDA Number | ASTM/EN/ISO Spec | Brass Alloy Composition | Key Properties | Common Applications |

|---|---|---|---|---|---|

| Cartridge Brass | C26000 | ASTM B36, EN CW505L | ~70% Cu, 30% Zn | Excellent ductility, deep drawability | Ammunition cases, radiator cores, musical instruments, deep-drawn parts |

| Free-Cutting Brass | C36000 | ASTM B16, EN CW603N | ~61.5% Cu, 35.5% Zn, 2.5-3.7% Pb | Outstanding machinability, moderate strength | Screws, fittings, valve stems, precision machined parts |

| Naval Brass | C46400 | ASTM B21, EN CW712R | ~59% Cu, 40% Zn, 1% Sn | High corrosion resistance (esp. seawater), good strength | Marine hardware, propeller shafts, condenser plates |

| Leaded Brass (Architectural Bronze) | C38500 | ASTM B455, EN CW614N | ~57% Cu, 40% Zn, up to 3.5% Pb | Good machinability, formability, decorative finish | Extruded shapes, decorative trim, hardware |

| Red Brass | C23000 | ASTM B134, EN CW502L | ~85% Cu, 15% Zn | Superior corrosion resistance, reddish hue | Plumbing fittings, valves, ornamental castings |

| Lead-Free (DZR) Brass | C69300, C87850 | ASTM B371, EN CW511L | Cu-Zn-Si (no Pb) | Dezincification resistance, safe for potable water | Drinking water fittings, plumbing, eco-friendly parts |

Each grade’s composition of brass—from high-copper red brasses to silicon- or tin-modified naval brasses—directly drives its mechanical behavior. For example, cartridge brass’s balanced copper-zinc ratio gives it the flexibility for deep drawing, while free-cutting brass’s lead content makes it the benchmark for machinability. Dezincification-resistant (DZR) brasses, often lead-free, are now standard for potable water systems to ensure safety and longevity. Please note that although C38500 is often referred to as 'architectural bronze', it is metallurgically classified as a brass due to its copper-zinc alloy composition.

Standards and Designations: Navigating UNS, ASTM, EN, and ISO

Confused by all the codes and numbers? You’re not alone. Brass materials are tracked globally using several designation systems:

- UNS/CDA (Unified Numbering System/Copper Development Association): The most common in North America—C26000, C36000, etc.

- ASTM: Widely used for product forms and test methods—ASTM B16, B36, B21, and others.

- EN (European Norm): CW-series numbers like CW505L or CW614N, common in Europe.

- ISO: International standards for composition, dimensions, and testing.

When specifying brass alloys, always cross-check the grade number and standard to ensure you’re getting the right material for your process and region. Manufacturers and suppliers can provide official specification sheets or mill test reports on request.

Selecting Grades by Forming, Machining, and Corrosion Needs

How do you choose the right grade among so many types of brass? Start by matching the alloy’s strengths to your application:

- Forming: Need deep drawing or bending? Choose cartridge brass (C26000) or red brass (C23000) for their ductility.

- Machining: For parts requiring extensive turning, drilling, or threading, free-cutting brass (C36000) or leaded Brass (Architectural Bronze) (C38500) is ideal.

- Corrosion Resistance: For marine or aggressive water environments, naval brass (C46400) or DZR brass (C69300) offers superior protection.

- Potable Water Safety: Always specify lead-free or DZR grades, such as C69300 or C87850, to comply with health regulations.

Remember, brass alloy composition is the key to performance—minor tweaks in copper, zinc, or added elements can dramatically shift machinability, strength, and corrosion resistance. Always review the alloy’s datasheet and, when in doubt, consult with your supplier or a materials engineer for guidance.

Practical Sourcing Tips for Brass Materials

- Request mill test reports to confirm composition of brass meets your requirements

- Check for low-lead or lead-free certification if using for drinking water or food contact

- Match temper (hardness/softness) to your forming or machining process

- Verify product form (bar, sheet, tube, casting) and standard before ordering

- Ask for documentation referencing ASTM, EN, or ISO standards for traceability

Understanding what metals are in brass and how each grade is standardized will help you specify the right brass materials for any project—from ornate trim to high-pressure valves. Up next, we’ll cover hands-on fabrication and finishing tips to get the best results from your chosen alloy.

How to Make, Shape, and Finish Brass

Machining Brass: Setup, Tools, and Coolant

When you’re machining brass, you’ll quickly discover why it’s favored for precision work. Its excellent machinability means you can achieve tight tolerances and smooth finishes—if you follow a few best practices. Wondering how do you make brass parts that are crisp and defect-free? Here’s what matters most:

- Do use sharp, high-speed steel or carbide tools—free-cutting brasses (like C36000) are designed for this and reduce tool wear.

- Do optimize your feeds and speeds—brass allows for higher cutting speeds than steel, but always check your specific alloy’s recommendations.

- Do use adequate lubrication or coolant to prevent heat buildup, which can cause smearing or burrs.

- Don’t use excessive pressure or dull tools—these can lead to poor surface finish or even part deformation.

- Don’t neglect chip evacuation—brass chips can clog tools, so keep the workspace clear for best results.

Brass is not a soft metal in the way pure copper or aluminum can be, but its balanced brass hardness (especially in free-machining grades) makes it ideal for intricate work without excessive tool wear.

Forming and Bending Without Cracking

Need to bend or shape brass sheet or tube? The key is matching the right alloy and temper to your process. Alpha brasses (like cartridge brass) are highly ductile and perfect for cold forming—think deep drawing or tight bends. But push too far, and even these can crack, especially if the radius is too tight or the material is too hard.

- Do anneal brass before forming if you need extreme bends—this softens the alloy and increases ductility.

- Do use gradual bends and appropriate tooling to avoid stress concentrations.

- Don’t bend hard-temper brass without softening—it’s more likely to crack or split.

- Don’t forget to consider grain direction, especially in brass sheet, as bending across the grain can reduce the risk of fracture.

Match temper to forming radius for consistent results.

| Brass Alloy Family | Best Process Route | Notes |

|---|---|---|

| Alpha Brass (Cartridge, C26000) | Cold work (bending, drawing) | Anneal for tight radii; excellent ductility |

| Alpha-Beta Brass (Naval, C46400) | Hot work (forging, forming) | Heat to 600–800°C for best results |

| Free-Cutting Brass (C36000) | Machining focus | Not ideal for bending; best for turning/drilling |

Soldering, Brazing, and Finishing Choices

Joining brass? Soft soldering works for low-stress plumbing, but for strength and leak-proof joints, silver brazing is the go-to. The trick is to use a filler with a lower melting point than the base brass—typically between 900°F and 1,900°F. This ensures you don’t melt the part itself (what temperature does brass melt? Most brasses soften above 900°C/1,650°F, so stay well below this for joining).

- Do thoroughly clean and flux all joint surfaces to prevent oxidation and ensure a strong bond.

- Do clamp parts securely and apply even heat to avoid distortion.

- Don’t overheat—excessive temperature can cause zinc loss (dezincification) or weaken the joint.

- Don’t use welding unless you have experience and the right filler, as brass’s low melting point and zinc content can make it tricky.

For finishing, brass offers nearly endless options. Want a mirror shine? Polishing and buffing bring out its signature glow. Prefer a brushed or satin look? Use abrasive belts or brushes to create a low-gloss finish that hides fingerprints and minor scratches. Protective coatings—like lacquer or powder coat—help lock in the appearance and reduce tarnish.

- Do choose the finish based on application: lacquer for decorative, powder coat for durability, or plating for enhanced corrosion resistance.

- Do clean and degrease before finishing to ensure adhesion.

- Don’t skip surface prep—leftover oils or oxides will cause poor adhesion and uneven color.

With these fabrication tips, you’ll get the most from your brass—whether you’re machining, bending, joining, or finishing. Up next, we’ll explore how to select and specify the right brass for your application, ensuring safety, compliance, and long-term performance.

How to Choose and Specify the Right Brass for Your Application

Choosing Brass for Plumbing, Instruments, and Bearings

When it comes to selecting brass for your project, the right choice depends on more than just appearance or price. Start by asking: What is brass used for in your specific application? For plumbing and potable water, safety and compliance are non-negotiable. In musical instruments, workability and acoustic quality matter most. For bearings and wear parts, you may even need to weigh brass against alternatives like bronze.

- Plumbing and Potable Water: Always check if does brass contain lead. For drinking water systems, regulations often require low-lead or lead-free brass. Look for dezincification-resistant (DZR) grades in aggressive water environments to prevent failure and leaks. DZR brasses are specially formulated to resist zinc loss, which can otherwise weaken fittings and pipes.

- Musical Instruments: The right brass balances easy forming with a bright, resonant sound. Cartridge brass is a popular choice for its ductility and consistent tone.

- Bearings and Wear Items: While brass is popular for low-friction components, bronze often outperforms it for heavy-duty or marine use due to higher tin content and wear resistance. Ask yourself: is brass expensive compared to bronze, and does the application justify the cost?

- Marine and Outdoor Hardware: Brass resists corrosion but can brass rust? It won’t rust like steel, but in salty or high-chloride environments, it may suffer from dezincification unless you select the right alloy and finish. Protective coatings or periodic maintenance may be needed for longevity.

Avoiding Dezincification and Ensuring Potable Safety

Dezincification is a silent threat in plumbing and marine applications. It occurs when zinc leaches out, leaving behind a weakened, porous copper structure—a process that can cause leaks and failures over time. To avoid this, choose a DZR brass with added tin, arsenic, or other inhibitors. These alloys are engineered to withstand aggressive waters and are now the standard in many plumbing codes.

For potable water, always specify low-lead or lead-free brass. Regulations in many regions limit the amount of lead permitted in fittings and valves. Confirm documentation from your brass bar manufacturers—mill test reports and certificates of compliance are essential for safety and traceability.

Buyer Checklist and RFQ Specification Template

Not sure where to start? Here’s a practical checklist to help you specify brass for any application, whether you’re sourcing for plumbing, decorative hardware, or industrial parts. This ensures you get exactly what is in brass—and nothing less.

- Confirm alloy grade and designation system (UNS/ASTM/EN/ISO)

- Specify form and dimensions with tolerances and temper

- State low-lead or lead-free requirement for potable water if applicable

- Call out DZR requirement for high-chloride or warm waters

- Define finishing and appearance standards

- Require mill test reports and compliance certifications

- State inspection and acceptance criteria

Alloy: [UNS/CDA]. Standard: [ASTM/EN/ISO]. Form/Temper: [bar/sheet/tube, H/C/O]. Dimensions/Tolerances: […]. Mechanical Properties: […]. Corrosion Requirements: [DZR/other]. Compliance: [applicable potable-water or regional regulations]. Finish: […]. Certificates: [MTR, CoC]. Testing: [tensile, hardness].

What Metals Make Brass and When to Choose It

Remember, what metals make brass—mainly copper and zinc—dictate its performance. Small tweaks in composition can mean the difference between a safe, long-lasting installation and an early failure. If you’re unsure, consult with your supplier or a materials engineer, and always request documentation. This approach not only ensures compliance and safety but also helps you control costs and avoid surprises down the line. Next, we’ll explore how CNC machining can further optimize your brass components for precision and speed.

CNC Machining Brass Parts with Confidence

When CNC Machining Is Best for Brass

When you need brass components that are both precise and reliable, CNC machining stands out as the go-to manufacturing method. But why is this process so well-suited to brass? For starters, brass’s unique combination of softness, stability, and mechanical strength makes it easy to machine into complex shapes with tight tolerances—whether you’re making a single prototype or scaling up for full production. Free-cutting brasses, such as C36000, are especially prized for their ability to produce clean, accurate cuts with minimal tool wear, resulting in a superior surface finish and consistent part quality.

However, not all brass alloys behave the same way under the cutting tool. While free-cutting grades are ideal for high-speed, high-precision work, cartridge and naval brasses may require different tooling strategies or coolant setups to prevent smearing, burrs, or heat buildup. This means that understanding the specific brass material density, composition, and intended use of your brass component is key to optimizing your process and avoiding costly rework.

Design Features Suited to 4- and 5-Axis Brass Machining

Ever tried to machine a part with complex curves, angled holes, or undercuts? That’s where modern 4- and 5-axis CNC machining really shines. These advanced setups allow for the creation of intricate geometries in solid brass that would be impossible—or prohibitively expensive—using manual methods or basic 3-axis machines. The result: highly detailed, functionally optimized brass components delivered with exceptional repeatability.

- Precision valve bodies with intersecting channels

- Instrument valve blocks and manifolds for fluid control

- Miniaturized connectors and electrical contacts

- Custom medical fittings and surgical hardware

- Decorative hardware with complex reliefs or engravings

- High-frequency RF or microwave components

For these demanding applications, the ability to hold tolerances as tight as +/- 0.005mm isn’t just a bonus—it’s a requirement. The machinability of brass, combined with advanced CNC equipment, makes it possible to achieve these specifications efficiently, even for small-batch or prototype runs.

Partnering with a Certified Shop for Brass Components

With so many variables—brass alloy selection, tool geometry, coolant choice, and post-processing—navigating CNC brass machining can feel overwhelming. That’s where working with a certified, experienced partner like XTJ makes all the difference. XTJ leverages state-of-the-art 4- and 5-axis machining centers, delivers tolerances down to +/- 0.005mm, and offers lead times as fast as 3 days. Their ISO 9001:2015 and IATF16949 certifications ensure that every solid brass part meets strict quality and traceability standards—critical for industries like aerospace, medical, and electronics.

| Provider | Machining Capability | Tolerance | Lead Time | Engineering Support | Quality Certifications | Pros | Cons |

|---|---|---|---|---|---|---|---|

| XTJ (Certified Shop) | 4- and 5-axis, complex geometries, 30+ materials | Up to +/- 0.005mm | As fast as 3 days | Dedicated DFM and process support | ISO 9001:2015, IATF16949 | Rapid turnaround, tight tolerance, risk mitigation, strict quality | May be higher cost for low-complexity, high-volume parts |

| In-House Machining | Typically 3-axis; limited complexity | Varies; often +/- 0.05mm or higher | 1–4 weeks (setup dependent) | Limited (depends on staff) | Shop-specific or none | Control over scheduling, potential cost savings on simple parts | Longer lead times, higher scrap risk, limited geometry |

Choosing a partner with advanced capability and robust quality systems helps de-risk your project—especially when your brass component must meet regulatory or customer requirements. You’ll benefit from expert advice on material selection, process optimization, and even surface finishing, ensuring every part performs as intended.

Next, we’ll wrap up by showing how to move from understanding brass’s properties and fabrication methods to specifying and sourcing high-quality brass components for your next project.

How to Specify and Source Brass with Confidence

Key Takeaways for Choosing Brass

After exploring what is brass, its diverse grades, and the ways it can be formed or machined, you might wonder: how do you make the final call for your project? Whether you're a buyer, engineer, or designer, the process comes down to a few practical steps. Ask yourself: Is brass an element? No—it's an alloy, engineered for specific applications. Is brass a metal? Absolutely, but it's the copper-zinc blend that gives it its signature properties. How to know if something is brass? Look for that golden color, check its non-magnetic nature, and confirm with supplier documentation if needed.

- Match the alloy to your application—consider strength, corrosion resistance, machinability, and compliance needs.

- Reference official standards (ASTM, EN, UNS/CDA) to ensure you get the right grade.

- Always request mill test reports and certificates of compliance to validate composition and properties.

- For high-precision or critical-use parts, prioritize suppliers with robust quality management systems (ISO 9001:2015, IATF16949).

- Don't overlook design for manufacturability—get DFM feedback early to avoid costly revisions.

Specifying Grades, Tolerances, and Documentation

Specifying brass for your project means more than picking a grade off a chart. It’s about communicating clear, testable requirements to your supplier. Is brass an alloy? Yes—and the exact composition will dictate your part's performance and compliance. Here’s a streamlined approach to ensure reliable outcomes:

- Select the appropriate brass grade based on function (e.g., cartridge, free-cutting, naval, or DZR for potable water).

- Define all relevant standards: include UNS/CDA, ASTM/EN/ISO codes in your RFQ or purchase order.

- Specify tolerances, mechanical properties, and surface finishes—especially for components that must fit or seal precisely.

- Request full documentation: mill test reports, certificates of compliance, and, where needed, third-party inspection records.

- Validate manufacturability—ask your supplier or CNC partner to review the design for process risks.

Specifying standards, tolerances, and documentation upfront is the surest way to avoid downstream issues and costly rework.

From Prototype to Production with Trusted CNC Partners

When your project calls for tight tolerances, intricate geometries, or rapid turnaround, working with a certified CNC machining partner is often the best path forward. Providers like XTJ offer advanced 4- and 5-axis machining, ultra-precise tolerances (down to +/- 0.005mm), and engineering support to help you move from prototype to production without compromising quality. Their ISO 9001:2015 and IATF16949 certifications, along with fast lead times and multi-material expertise, make them a strong choice for regulated industries or when reliability is non-negotiable.

- Select your brass alloy and confirm it meets your application’s demands.

- Reference the correct standard and define all specs in your order.

- Validate manufacturability—leverage CNC partner expertise for DFM and tolerance feasibility.

- Request a detailed quote, including documentation and lead time commitments.

- Review sample or prototype parts to ensure all requirements are met before scaling up.

By following these steps, you’ll not only answer the question is brass an element (it’s not—it’s an alloy), but you’ll also gain the confidence to specify, source, and deploy brass components that perform as promised, project after project. For complex or high-stakes applications, partnering with a vetted CNC supplier like XTJ ensures your brass parts are delivered on time, within tolerance, and with full traceability—setting you up for long-term success.

Frequently Asked Questions About Brass

1. Why is brass so cheap compared to other metals?

Brass is generally more affordable because it is made from copper and zinc, both of which are less costly than metals like gold or tin. Its manufacturing process is also simpler, keeping production costs lower and making brass a cost-effective choice for many applications.

2. What is brass made of and how does its composition affect performance?

Brass is primarily a copper and zinc alloy. The ratio of copper to zinc can be adjusted to change properties like color, strength, and corrosion resistance. Small additions of other elements, such as lead or tin, can further enhance machinability or durability, allowing brass to be tailored for specific uses.

3. How can you tell the difference between brass, bronze, and copper?

Brass typically has a yellow to gold color, copper is reddish-brown, and bronze is dull gold or brownish. None are magnetic. Brass is a copper-zinc alloy, bronze is mainly copper and tin, and copper is a pure element. Checking color, weight, and using a magnet can help you distinguish between them.

4. Can brass rust or tarnish over time?

Brass does not rust like iron, but it can tarnish, developing a dull or greenish patina due to exposure to air and moisture. In certain environments, brass may suffer from dezincification, where zinc leaches out, but choosing the right alloy can minimize this risk.

5. When should you choose CNC machining for brass parts?

CNC machining is ideal for brass components that require tight tolerances, complex shapes, or high-quality finishes. Certified CNC shops, like XTJ, provide advanced 4- and 5-axis capabilities, rapid turnaround, and quality assurance, making them suitable for demanding industries such as aerospace, medical, and electronics.