Stainless Steel Bolts Specs Decoded: Strength, Grades, Standards

Stainless Steel Bolts Fundamentals and Use Cases

Ever wondered why stainless steel bolts are the go-to choice for demanding environments? If you’ve ever built a deck near the ocean, assembled food processing equipment, or specified hardware for medical devices, you’ve likely relied on these fasteners—often without a second thought. Let’s break down what makes stainless bolts unique, how they differ from stainless steel screws, and why they’re so widely trusted in critical applications.

What Are Stainless Steel Bolts?

Stainless steel bolts are threaded fasteners designed for high-strength, high-reliability joints. Their key feature is corrosion resistance, made possible by a minimum of 10.5% chromium content, which forms a protective oxide layer. This sets them apart from ordinary steel bolts, especially in environments where rust or chemical attack is a concern. You’ll find stainless bolts in everything from bridges and marine docks to food-grade machinery and hospital equipment, where hygiene and long-term durability are non-negotiable. The term “ss bolts” is often used interchangeably with “stainless steel bolt,” but both refer to the same corrosion-resistant hardware family.

Bolt Versus Screw Differences Explained

Sounds complex? Actually, the difference between bolts and screws comes down to how they’re used and installed. Bolts are typically paired with nuts and washers to clamp two or more components together, while screws are driven directly into the material, often without a nut. Bolts are designed for high-tension, structural applications where easyWonArn removal and reassembly are important. In contrast, stainless steel screws excel in lower-tension or thinner materials, like wood or sheet metal, where direct engagement is possible. For many projects, you’ll encounter both bolts and screws, but knowing when to use each can make or break reliability.

Core Components: Head, Shank, Threads, and Nuts

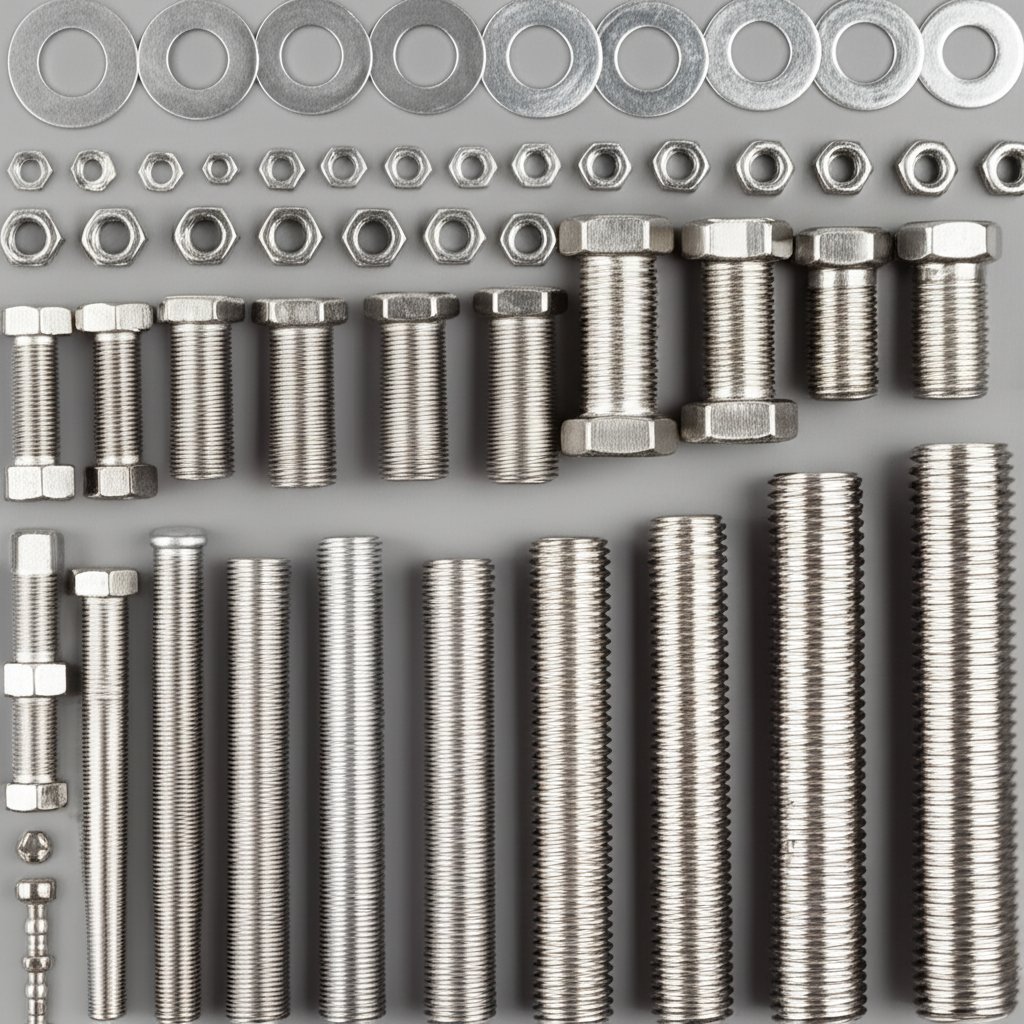

To fully understand stainless steel bolts, it helps to visualize their main components and the choices available for each:

- Hex Head: The most common style for structural and industrial use—easy to grip with wrenches or sockets.

- Carriage Head: Rounded top with a square neck; popular for wood and outdoor furniture.

- Socket Head: Recessed hex drive for compact, high-strength connections in tight spaces.

- Lag Bolt: Heavy-duty, large thread; bites into wood like an oversize screw for decks and framing.

- Eye/U-Bolt: Specialty shapes for lifting, anchoring, or pipe support.

The anatomy of a bolt includes:

- Head: The shaped top, designed for wrench or tool engagement.

- Shank: The unthreaded portion (if present) offering alignment and shear strength.

- Threads: The helical grooves that accept a nut or bite into material.

- Nuts and Washers: Often paired with bolts for secure, vibration-resistant assemblies—hence the term “stainless steel nuts and bolts.”

Matching Stainless Bolt Families to Environments

| Environment | Recommended Stainless Family | Typical Use Case |

|---|---|---|

| Marine / Coastal | Austenitic (304/316) | Docks, boats, saltwater structures |

| Outdoor Structural | Austenitic | Bridges, railings, building exteriors |

| Food Processing | Austenitic | Sanitary equipment, conveyors |

| Medical Equipment | Austenitic | Clean rooms, surgical devices |

| High Load / Wear | Martensitic | Pumps, valves, heavy machinery |

| Aggressive Chemicals | Duplex | Industrial processing, chemical plants |

Across these sectors, stainless bolts deliver unmatched corrosion resistance, hygiene, and lifecycle value. They’re often specified by architects and engineers who want to minimize maintenance and avoid premature failures. Assemblies using bolts and screws made from stainless are especially valued in environments where rust or contamination can’t be tolerated.

When long-term reliability and corrosion resistance matter most, stainless steel bolts consistently outperform coated carbon steel—especially in marine, food processing, and outdoor structural applications.

Limitations and Reference Standards

No material is perfect. Stainless steel bolts can be susceptible to galling (thread seizing during tightening) and, in some grades, to chloride-induced corrosion. Understanding your environment and consulting standards like ASTM, ASME, ISO, and NACE is crucial to selecting the right fastener and terminology.

In summary, whether you’re sourcing stainless steel nuts and bolts for a new marina, selecting ss bolts for food-grade machinery, or comparing bolts and screws for a complex project, understanding these fundamentals will set you up for success. In the next section, we’ll dive deeper into grades and standards to help you choose the right stainless steel bolt for your needs.

Stainless Grades and Standards You Should Know

Choosing the right stainless steel bolt can seem overwhelming—especially when you’re faced with terms like “A2-70,” “316 A4,” or “F593C bolt grade.” So, how do you decode these grades and standards to make a confident, informed choice? Let’s break it down, step by step, so you can match the right fastener to your environment and performance needs.

Stainless Steel Bolt Grades Overview

The world of stainless steel bolt grades is organized around three main families: austenitic, martensitic, and duplex. Each family is defined by its unique chemical composition and resulting properties, making some grades better for corrosion resistance, while others excel in strength or heat treatability.

| Grade | Family | Corrosion Notes | Mechanical Behavior | Typical Specs & Applications |

|---|---|---|---|---|

| 304 / 18-8 (A2-70) | Austenitic | Excellent general corrosion resistance; not for high-chloride (marine) environments | Non-magnetic; not hardenable by heat; good ductility | ASTM F593, ISO 3506-1; construction, food, medical, general industrial |

| 316 (A4-70, 316 A4 stainless steel) | Austenitic | Superior corrosion resistance, especially in saltwater and chemicals (due to molybdenum) | Non-magnetic; not hardenable by heat; slightly lower strength than 304 | ASTM F593, ISO 3506-1; marine, chemical plants, pharmaceutical, food processing |

| 410 | Martensitic | Moderate corrosion resistance; can rust in aggressive or wet environments | Magnetic; can be heat treated for high strength and hardness | ASTM F593, ASME B18; pumps, valves, tools, wear parts |

| Duplex | Duplex | Very high corrosion resistance, especially to chlorides and stress corrosion cracking | Magnetic; higher strength than austenitic grades; some heat treatability | ASTM F593, ISO 3506; offshore, chemical processing, structural |

304, 316, 410, and Duplex Compared

Imagine you’re specifying hardware for a new marina or a chemical plant. You’ll notice that 316 stainless steel bolts (A4 grade) stand out for their resistance to saltwater and harsh chemicals—thanks to added molybdenum. In contrast, 304 (A2) is a cost-effective, all-purpose option for most indoor and outdoor uses. Martensitic 410 bolts are your go-to for high strength and wear resistance, but they’re less corrosion-resistant, making them better suited for dry or mildly corrosive environments. Duplex bolts provide a best-of-both-worlds solution, combining high strength and exceptional resistance to chloride-induced corrosion.

Here’s a quick way to remember the differences:

- 304/A2 (A2-70 the bolt grade): Best for general use, food processing, and medical equipment.

- 316/A4 (316 a4 stainless steel): Essential for marine, coastal, and chemical applications.

- 410: Select where high strength and hardness matter more than corrosion resistance.

- Duplex: Choose for aggressive chemical or chloride-rich settings, like offshore structures.

When to Choose A2 Versus A4

Still unsure which grade is right for you? Ask yourself these questions:

- Will the bolt be exposed to saltwater or aggressive chemicals?

- Is strength or corrosion resistance more critical for your application?

- Does the fastener need to be non-magnetic?

- Are you working in high-temperature or hygienic environments?

If you need a fastener for general industrial or indoor use, a2 70 stainless steel is often the best value. For marine, pharmaceutical, or chemical processing, 316 stainless steel bolts (A4) are the clear winner. If you’re working in a unique or highly demanding environment, consider consulting the ISO 3506 standard or ASTM F593 for detailed guidance.

-

Selection Criteria for Stainless Steel Bolt Grades:

- Operating environment (humidity, chlorides, chemicals)

- Required mechanical strength

- Temperature extremes

- Required non-magnetic properties

- Ease of fabrication or machining

- Cost and availability

For a full overview of how to select and specify the right grades of stainless bolts, always reference industry standards, such as ASTM F593/F594 for bolts and nuts, ASME B18 for dimensions, and ISO 3506 for international alignment. NACE standards are also recommended for environments with high corrosion risk.

In the next section, we’ll explore how these grades translate into mechanical performance—covering yield, tensile, and proof load—so you can confidently set strength targets for your application.

Mechanical Properties and Load Considerations

Ever wondered what truly determines the strength and reliability of stainless steel bolts in your application? Whether you’re designing a bridge, assembling food-grade equipment, or specifying hardware for a pump, understanding the mechanical properties—like tensile strength, yield strength, and proof load—is essential. Let’s break down these concepts, see how they relate to real-world performance, and explore why factors like friction and thread condition matter as much as material grade.

Understanding Stainless Bolt Strength

When you tighten a bolt, you’re not just joining two parts—you’re creating a carefully balanced clamp load that resists vibration, shock, and environmental stresses. The core mechanical properties that govern stainless steel bolt strength include:

- Tensile Strength: The maximum pulling force a bolt can withstand before breaking. For example, the ultimate tensile strength of stainless steel grades like 304 or 316 is a key benchmark for structural integrity.

- Yield Strength: The load at which a bolt begins to deform permanently. The yield strength 18 8 stainless steel (another name for 304) is often referenced for general-purpose fasteners.

- Proof Load: The maximum load a bolt can handle without permanent deformation—used as a practical limit for design and installation.

- Shear Strength: The force a bolt can resist along its cross-section, such as when a bolt is loaded sideways. The shear strength of stainless steel 304 is critical in applications like flanges and brackets.

- Hardness and Ductility: Hardness relates to a bolt’s resistance to indentation, while ductility is its ability to stretch without breaking—both impact how a bolt behaves under load or shock.

- Fatigue and Temperature Effects: Repeated loading and high temperatures can reduce the long-term performance of even high strength stainless steel bolts.

Standards such as ASTM F593 and ISO 3506 specify the mechanical property requirements for each grade and property class. Always consult these standards or manufacturer datasheets for exact values—never rely on generic charts or assumptions.

Yield, Tensile, and Proof Load Explained

Sounds technical? Here’s a simple way to visualize it: imagine pulling on a rope. The rope stretches a little (elastic), then stretches more and doesn’t return to its original length (yield), and finally snaps (tensile failure). Stainless steel bolts behave the same way under load. Setting the right preload (the tension in the bolt after tightening) is crucial for joint reliability and safety.

Different property classes—like "A2-70" or "A4-80"—map to specific strength levels, which are defined by standards. For example, the ultimate tensile strength of 304 stainless steel (A2-70) is a common reference point for general-purpose fasteners, while property classes like A4-80 offer higher strength for demanding environments.

| Grade | Property Class | Qualitative Strength | Common Use |

|---|---|---|---|

| 304 (18-8) | A2-70 | Good general strength; suitable for most industrial and structural uses | Food, medical, construction |

| 316 | A4-70, A4-80 | Similar to 304, with better corrosion resistance; A4-80 is higher strength | Marine, chemical, pharmaceutical |

| 410 | C1-70 | Higher strength, moderate corrosion resistance; can be heat treated | Pumps, valves, wear parts |

| Duplex | D2-70, D2-80 | Very high strength and corrosion resistance | Offshore, chemical processing |

Note: Populate numeric values (tensile, yield, proof load) only from authoritative standards or manufacturer datasheets.

Torque, Preload, and Friction Considerations

Here’s a question: does tightening a bolt to the same torque always give you the same clamp force? Not at all! In reality, the relationship between torque and preload is heavily influenced by friction—both under the bolt head and in the threads. According to industry research, only about 10% of the torque you apply actually turns into useful preload; the rest is lost to friction (Nord-Lock).

Even small changes in surface finish, lubrication, or thread condition can cause significant scatter in preload. For stainless steel fasteners, which are prone to galling and seizing, using the right lubricant or anti-seize compound is especially important for repeatable, reliable assembly.

Preload accuracy depends more on controlling friction than on the torque value itself—always test and adjust for your specific application.

- Surface finish (smooth vs. rough threads)

- Lubrication (dry, oiled, anti-seize)

- Thread tolerance and fit

- Washer type or presence

For high strength stainless steel bolts, especially in critical joints, always follow the torque recommendations from the fastener manufacturer or refer to the applicable standard. This ensures you achieve the intended clamp load without risking premature loosening or thread damage.

In summary, specifying the right stainless steel bolt isn’t just about picking a grade—it’s about understanding how mechanical properties, property class, and installation variables combine to ensure long-term reliability. In the next section, we’ll discuss how to size and select threads and head dimensions for the perfect fit in your application.

Sizing Threads and Head Dimensions That Fit

When you’re choosing stainless steel hex bolts for your next project, how do you ensure they’ll fit, hold, and last as long as you need? From selecting the right diameter and thread pitch to understanding head styles and shank length, getting these details right is crucial for performance and reliability. Let’s make sense of the key sizing and dimensional factors for stainless steel hex head bolts, drawing on industry standards like ASME B18 and ISO 4014/4017.

Selecting Diameter, Length, and Pitch

Imagine you’re assembling a heavy-duty bracket or a piece of outdoor furniture. The first thing you’ll notice is that not all threaded bolts are created equal. The diameter of a stainless steel bolt determines its strength and the size of the hole it fits. Larger diameters (like 1/2 inch or M12) offer greater load capacity but require more space and heavier tools. The length is measured from the bearing surface under the head to the tip, excluding the head itself—longer bolts allow deeper engagement but can lead to wasted material if oversized.

Thread pitch—the distance between threads—affects how easily the bolt turns and how well it holds. Fine threads (more threads per inch or millimeter) provide better grip and are ideal for precision or vibration-prone assemblies, while coarse threads are faster to install and more forgiving in softer materials. Standard pitch values are defined in ASME and ISO tables for each nominal size.

| Nominal Size | Standard Thread Pitch | Matching Nut Series | Matching Washer Series |

|---|---|---|---|

| 1/4" (Inch) | 20 TPI (coarse), 28 TPI (fine) | 1/4" Hex Nut | 1/4" Flat/Lock Washer |

| M10 (Metric) | 1.5 mm (standard), 1.25 mm (fine) | M10 Hex Nut | M10 Flat/Lock Washer |

| M12 (Metric) | 1.75 mm (standard), 1.5 mm (fine) | M12 Hex Nut | M12 Flat/Lock Washer |

| 1/2" (Inch) | 13 TPI (coarse), 20 TPI (fine) | 1/2" Hex Nut | 1/2" Flat/Lock Washer |

Note: Always confirm with the latest ASME B18 or ISO 4014/4017/4032 standards for precise dimensions.

Thread Engagement and Shank Considerations

Ever wondered how much of a threaded bolt needs to be engaged in the mating material for full strength? As a rule of thumb, a thread engagement length equal to the bolt’s nominal diameter is usually sufficient to prevent thread shear failure (Mechanicalc). For example, a 10mm diameter bolt should have at least 10mm of threads engaged.

The bolt shank—the unthreaded portion between the head and threads—plays a key role in alignment and shear strength. If the shear plane (where force is applied sideways) passes through the shank, the joint is stronger than if it passes through the threads. When using stainless steel hex head bolts in structural joints, ensure the shank covers the grip length (the total thickness of clamped parts) when possible.

- Determine required load and select bolt diameter for strength.

- Choose thread class (coarse or fine) based on installation speed, grip, and material.

- Set engagement length: aim for at least one diameter of thread engagement.

- Verify head clearance and select a head style that fits your space and tool access.

- Select washer type (flat, lock, or spring) to distribute load and prevent loosening.

- Common mistakes to avoid:

- Mixing coarse and fine threads in the same assembly

- Underestimating grip length, leading to too few threads engaged

- Choosing a shank bolt that is too short, resulting in threads in the shear plane

- Overlooking washer thickness, which affects thread engagement

Head Styles and Wrench Clearance

Hex head stainless bolts are favored for their ease of installation with standard wrenches or sockets. Head size is standardized: for example, a 1/2-inch bolt typically uses a 3/4-inch wrench, while an M10 bolt uses a 17mm wrench. Larger heads allow higher torque but need more clearance. If space is tight, consider socket head or button head alternatives, but always confirm that your tool will fit around the head during assembly and maintenance.

When installing stainless steel hex bolts or other threaded bolts, always double-check the available clearance for your chosen head style and tool. This ensures that you can apply the correct torque without risk of rounding off the head or damaging surrounding parts.

Proper sizing and thread engagement are essential for the full strength and reliability of any bolted joint—never sacrifice fit for convenience.

Ready to move from sizing to installation? Up next, we’ll cover best practices for torque application, lubrication, and hardware choices to ensure your stainless steel hex head bolts perform as intended throughout their service life.

Installation Best Practices to Avoid Failures

Ever tightened a bolt and found it seized halfway, or noticed a joint that loosens after a few thermal cycles? Proper installation of stainless steel bolts and nuts is more than just turning a wrench. It’s about understanding the unique properties of stainless, applying the right techniques, and choosing the correct hardware to guarantee performance and longevity. Let’s walk through the best practices that help you avoid common pitfalls and ensure your stainless nuts bolts assemblies stand the test of time.

Preventing Galling With Proper Lubrication

Galling is one of the most frustrating—and costly—failures you can encounter when working with stainless steel fasteners. Imagine you’re installing a bolt nut stainless steel pair, and suddenly the threads seize, refusing to turn or back out. This is galling: a form of cold welding caused by intense friction and heat between the threads. Stainless, aluminum, and titanium are especially prone to it due to their protective oxide coatings, which can break down under pressure and heat.

- Always apply a metal-free anti-seize or never-seize lubricant to the threads before assembly. This dramatically reduces friction and heat, lowering the risk of galling.

- Install bolts and nuts at a slow, steady pace—avoid high-speed power tools, which can rapidly generate heat and friction.

- Inspect threads for dirt, burrs, or damage before installation; even minor imperfections can increase friction and trigger galling.

- Store fasteners in a cool, dry environment to prevent thermal buildup before use.

By taking these steps, you not only protect your stainless steel bolts and washers from seizing but also make future maintenance and disassembly far easier.

Washer and Locking Hardware Selection

Choosing the right washers and locking hardware is essential for joint reliability. Flat washers distribute the load and protect surfaces, while spring lock washers and locknuts add resistance to loosening from vibration or thermal cycling. When assembling bolts with nuts, always match the washer and nut material to the bolt—this prevents galvanic corrosion and ensures even load transfer.

- Use flat washers under both the bolt head and nut to prevent surface marring and distribute clamping force.

- Spring lock washers or locknuts are recommended in assemblies subject to vibration or cyclic loading.

- For critical joints, consider prevailing torque nuts for added security.

- Never mix materials—always use stainless steel bolts and washers together for optimal corrosion resistance.

Torque Application and Retention

Correct torque application ensures your stainless nut and bolt assembly achieves the right preload for joint integrity. But here’s the catch: torque-to-preload relationships are highly sensitive to friction. If you change the lubrication, finish, or washer type, the required torque value can change significantly. That’s why it’s crucial to reference the manufacturer’s torque chart for the specific bolt grade, diameter, finish, and lubrication condition.

- Inspect all fasteners and mating parts for defects or contamination before installation.

- Clean and lubricate threads with a recommended anti-seize compound.

- Hand-tighten all bolts with nuts to ensure proper alignment and thread engagement.

- Use a calibrated torque wrench to tighten bolts in a star or crisscross pattern for even load distribution.

- Recheck torque after initial tightening, especially after the first thermal cycle or if the assembly is subject to vibration.

- Do:

- Use the correct grade of nut for your bolt.

- Verify full thread engagement—at least one full thread should protrude past the nut.

- Apply even torque in sequence to prevent distortion.

- Consider locknuts or prevailing torque nuts in dynamic or high-vibration settings.

- Don’t:

- Over-torque or use power tools at high speed.

- Cross-thread bolts and nuts—always start by hand to ensure alignment.

- Mix materials or use mismatched stainless steel bolts and washers.

- Ignore re-torque checks after thermal cycling or heavy use.

Torque values can change dramatically with different lubricants or finishes—always consult the manufacturer’s chart for your exact assembly conditions.

By following these field-proven steps, you’ll dramatically reduce the risk of installation failures, galling, or premature loosening in your stainless steel bolts and nuts assemblies. Next, we’ll explore common failure modes and how to troubleshoot them—so you’re prepared for any challenge in the field.

Failure Modes, Causes, and Mitigation Strategies

Ever installed stainless steel bolts in aluminum only to find them seized, cracked, or corroded months later? Even the toughest fasteners can fail if the environment or installation isn’t right. Let’s explore the most common failure modes—galling, chloride stress corrosion cracking (SCC), and hydrogen embrittlement—so you can spot issues early and take action before they turn into costly problems.

Recognizing and Preventing Galling

Galling happens when threads bind so tightly during tightening that they seize, sometimes to the point of "cold welding." If you’ve ever had a stainless fastener refuse to budge or break loose, you’ve seen galling in action. This is especially common with stainless steel bolts and nuts due to the metal’s "sticky" properties and relative softness. Friction and heat build-up, damaged threads, or high-speed installation all increase the risk.

| Failure Mode | Mitigation Strategy |

|---|---|

| Galling (thread seizing) |

|

For critical joints—like where stainless steel bolts in aluminum are used—always check for galling risk, as dissimilar metals can also trigger galvanic corrosion. Grade 8 stainless steel bolts may offer higher strength but are not immune to galling if improperly installed.

Managing Chloride Stress Corrosion Cracking

Imagine a stainless bolt that looks fine on the outside but develops branched, brittle cracks from the inside out—often in warm, humid, or salty environments. That’s chloride stress corrosion cracking (SCC), a serious risk for austenitic grades like 304 and 316 ss bolts, especially above 60°C or when chlorides are concentrated from evaporation (SSINA). Even small chloride concentrations can trigger SCC, particularly at wet/dry interfaces or where heat is present.

| Failure Mode | Mitigation Strategy |

|---|---|

| Chloride SCC (cracking in austenitic bolts) |

|

If you’re working near pools, coastal areas, or chemical plants, upgrading to 316 ss bolts or duplex alloys is often the best defense. Remember, the stainless steel 304 shear strength may be sufficient for many applications, but in chloride-exposed environments, 316 provides both superior corrosion resistance and reliable bolt strength.

Hydrogen Embrittlement Awareness

Sounds technical? Hydrogen embrittlement is a rare but dangerous failure mode where hydrogen atoms infiltrate the bolt, making it brittle and prone to sudden fracture. This is most common in high-strength, hardened fasteners or when bolts have been electroplated or exposed to acid cleaning. While austenitic stainless bolts are less susceptible, martensitic grades and some coated fasteners can be at risk.

| Failure Mode | Mitigation Strategy |

|---|---|

| Hydrogen Embrittlement (brittle fracture) |

|

For projects demanding high stainless bolt strength, such as grade 8 stainless steel bolts, always verify that the manufacturing process controls for hydrogen embrittlement—especially if coatings or high hardness are involved.

Checklist: Environment-Driven Grade Selection

- Marine, coastal, or poolside: Prefer 316 ss bolts or duplex grades

- High temperature or chemical exposure: Review application with a corrosion specialist

- Aluminum assemblies: Use isolation washers and avoid direct contact to minimize galvanic corrosion

- High strength needs: Confirm grade and check for embrittlement risk

- General outdoor use: 304 or 305 grades may suffice, but always review local conditions

Consulting NACE and ASTM standards is essential for diagnosing and mitigating corrosion—especially in aggressive or unpredictable environments. Standards offer proven guidance for selecting, installing, and maintaining stainless steel bolts to maximize service life and safety.

By understanding these failure modes and taking preventive steps, you’ll protect your investment, whether you’re specifying stainless steel bolts in aluminum, choosing 316 ss bolts for corrosive settings, or maximizing stainless bolt strength in structural projects. Next, we’ll discuss inspection and maintenance routines to catch issues early and extend the life of your fastener assemblies—because even the highest stainless steel 304 shear strength is only as good as your ongoing care.

Inspection, Maintenance, and Re-Torque Playbook

When was the last time you checked the condition of your stainless steel bolts nuts assembly? Whether you’re maintaining a bridge, a food processing line, or simply want your stainless steel hardware to last, routine inspection and maintenance are essential. Imagine catching a loose nut or early corrosion before it results in costly downtime or a critical failure—this is the value of a proactive approach.

Incoming and Pre-Install Inspection

Sounds complex? It’s really about knowing what to look for before installation. Start by verifying that all bolts, nuts, and washers arrive with the required paperwork (certifications, test reports) and match your order specifications. Next, inspect each component for proper stainless bolt markings, ensuring you can tell how to tell bolt grade and confirm authenticity. Visual checks are your first defense:

- Confirm presence and legibility of stainless bolt markings (grade, manufacturer, lot number)

- Check for correct finish and absence of rust, pitting, or discoloration

- Review paperwork for compliance with ASTM, ISO, or project specs

- Assess thread fit by hand—nuts should spin smoothly the full length

- Inspect for straightness, undamaged heads, and clean threads

- Retain all documentation for traceability and future audits

For critical jobs, a sample of fasteners may be tested in a calibrated tension device or checked for hardness and ductility as described in project specs (Caltrans Bridge Manual).

In-Service Checks and Re-Torque Scheduling

Once installed, the work isn’t over. In-service inspection is about catching issues before they become problems. You’ll want to look for:

- Signs of corrosion (rust, pitting, or white residue on stainless steel nuts or bolts)

- Physical deformation—bent bolts, stretched shanks, or "necking"

- Thread damage, galling, or stripped threads

- Loose or missing hardware (nuts, washers, bolts)

- Heat discoloration indicating overload or improper installation

Use a calibrated torque wrench to verify preload, especially after the first thermal cycle or major vibration event. If torque is lost or nuts turn before reaching the specified value, re-torque the entire joint according to the sequence recommended in your specs. For assemblies exposed to vibration or temperature swings, schedule periodic re-torque checks as part of your maintenance routine.

- Initial run-in check: Inspect and verify torque after installation and first use.

- Periodic interval inspections: Set based on environment—monthly for high-vibration, quarterly for most outdoor assemblies.

- Event-driven inspections: Always inspect after overloads, impact, or thermal cycling.

Always record torque condition and lubrication state during inspection—repeatability depends on knowing exactly how the joint was assembled and maintained.

Non-Destructive Evaluation Basics

Wondering how to spot hidden flaws without taking everything apart? Non-destructive testing (NDT) can help. For stainless steel hardware, common NDT methods include:

- Thread plug gauges: Verify internal and external thread fit without damaging parts

- Dye penetrant inspection: Reveals surface-breaking cracks on bolt heads or shanks

- Eddy current sensors: Detect subtle metallurgical changes or heat treatment issues, especially in high-strength stainless steel fasteners

Use only documented test methods and retain NDT records for critical joints or safety-related assemblies. For assemblies where knowing how to tell bolt grade is vital, NDT can also help confirm material and process compliance.

-

Inspection and Documentation Checklist:

- Visual check: finish, markings, corrosion, deformation

- Thread fit and engagement

- Paperwork: certifications, lot traceability, torque records

- Torque audit: as-installed and in-service values

- NDT as required by specs

- Lubrication state and hardware compatibility

By following this playbook, you’ll catch issues early, extend the life of your stainless steel nuts and bolts, and ensure that your stainless steel hardware delivers the reliability you expect. Up next, we’ll look at supplier vetting and documentation—so you can be confident every fastener meets your project’s quality requirements.

Supplier Vetting, Quality Assurance, and Documentation

Ever worried about whether your stainless steel bolts will actually meet the performance and compliance promises in your purchase order? Whether you’re sourcing from stainless steel bolts and nuts suppliers for a critical infrastructure project or buying stainless steel bolts online for a quick repair, robust supplier qualification and documentation are your best defense against costly surprises.

What to Request From Suppliers

Imagine you receive a shipment of fasteners—how do you know they’re truly up to spec? The answer is documentation and traceability. Here’s what you should always request from stainless steel fasteners suppliers or stainless steel hardware suppliers:

- Certified Mill Test Reports (CMTRs): These verify the chemical composition, mechanical properties, and heat treatment of the raw material. Look for a clear heat number that links each batch of bolts to its original production lot, allowing full traceability.

- Material Certificates: Confirm the grade (e.g., 304, 316, A2-70), dimensions, and any special conditions. These are essential for compliance with ASTM, ASME, or ISO standards.

- Mechanical Test Reports: Ensure proof load, tensile strength, hardness, and ductility results are included. These demonstrate conformity to the mechanical requirements of your chosen standard (like ASTM F593 or ISO 3506).

- Dimensional Inspection Reports: Verify that the bolts, nuts, and washers match the specified sizes, thread pitches, and tolerances.

- Heat/Lot Traceability: Every batch should be traceable from raw material through finished product, crucial for critical or safety-related applications.

- Compliance Declarations: If your project requires RoHS/REACH, or other regulatory compliance, request documented proof.

- Environmental Test Results: For aggressive or marine environments, request salt-spray (ASTM B117) or similar test data—but remember that stainless steel’s real-world corrosion resistance is best judged by material grade and service history, not just lab tests.

Essential Tests and Certifications

To ensure your fasteners are up to the task, leading stainless steel fastener suppliers should provide the following, either as standard or upon request:

| Document/Test | Purpose | Acceptance Criteria |

|---|---|---|

| Certified Mill Test Report (CMTR) | Verifies chemical and mechanical properties, heat treatment | Matches specified grade, mechanical values meet or exceed standard |

| Mechanical Test Report | Confirms tensile, proof load, hardness, ductility | Pass/fail per ASTM F593, ISO 3506, or buyer spec |

| Dimensional Inspection | Checks size, thread, and tolerance | Conforms to ASME B18, ISO 4014/4017, or custom drawing |

| Heat Number/Lot Traceability | Ensures full traceability from raw material to finished part | Each item or lot marked and recorded; traceable to CMTR |

| Regulatory Compliance Certificate | Confirms RoHS, REACH, or other requirements | Official declaration of compliance |

| Environmental Test (Salt Spray, ASTM B117) | Optional for severe environments | Interpret results with caution; prioritize material grade and service record |

Note: Always populate acceptance criteria with values from the applicable standard or your project specification.

Purchase Specification and Acceptance Checklist

Before ordering from stainless steel bolts and nuts suppliers or browsing stainless steel bolts online, create a clear, audit-ready purchase specification. Here’s a checklist to guide your process:

- Reference standards: ASTM F593/F594 (bolts/nuts), ISO 3506, ASME B18 (dimensions), NACE (corrosion)

- Specify required grade, property class, and finish (e.g., A2-70, 316, passivated)

- List mechanical and dimensional requirements

- Request CMTRs, mechanical test reports, and heat/lot traceability

- Include regulatory and environmental compliance needs

- Define acceptance criteria for each document/test

- Retain all documentation for project records and future audits

-

Key Standards Bodies and Documents to Consult:

- ASTM: F593 (bolts), F594 (nuts), F606 (test methods), B117 (salt spray)

- ASME: B18 series (dimensions, tolerances)

- ISO: 3506 (mechanical properties), 16228 (inspection documents)

- NACE: Corrosion standards for aggressive environments

For critical applications, heat-number traceability is non-negotiable—it’s your assurance that every fastener can be traced back to its original material and test results.

Whether you’re sourcing from stainless steel fasteners suppliers nearby or searching for stainless steel fasteners near me online, remember that robust documentation and supplier transparency are as important as the fasteners themselves. By following these best practices, you’ll reduce procurement risk, ensure compliance, and set the stage for successful, long-lasting installations. Next, we’ll show how rapid prototyping can help you validate bolt fit and performance before full-scale production.

Rapid Prototyping to De-Risk Bolt Selection

Ever installed a set of 4 inch bolts only to find the wrench doesn’t fit or the thread engagement is off? Imagine catching these issues before they hit your production floor. That’s the power of rapid prototyping for stainless steel bolts and their assemblies—giving you the confidence that every dimension, clearance, and interface is right before you commit to a full run.

Prototype to Validate Fastener Fit and Access

When you’re working with bolts 1/4 inch in diameter or specifying a 1/2 thru bolt for a critical fixture, even minor misalignments in hole size, thread depth, or head clearance can cause costly delays. Rapid prototyping lets you turn your CAD models into real, testable parts—so you can physically check:

- Wrench and tool access around bolt heads (especially for 3/4 bolts or tight assemblies)

- Thread engagement in mating parts (ensuring, for example, that 1/4 in bolts have full strength without bottoming out)

- Clearance for washers, nuts, or special locking features

- Potential for galling or fit-up issues in stainless steel threads

By building and testing these interfaces early, you’ll spot problems that 3D models alone can miss—saving time, material, and rework down the line.

Choosing the Right Prototyping Process

Not sure whether to use CNC machining, 3D printing, or injection molding for your prototype? Each process has its strengths depending on the bolt size, material, and the type of test you need. Here’s a comparative look at common prototyping options—notice how a service like XTJ stands out for its standards alignment and versatility:

| Process/Service | Best For | Speed | Material Choices | Surface Finish |

|---|---|---|---|---|

| XTJ Rapid Prototyping (CNC, Injection, Die Casting, ISO 9001:2015) | Functional bolt prototypes, DFM feedback, metal/plastic parts, test coupons | Rapid (days) | 50+ metals & plastics (inc. stainless, aluminum 6061/7075, engineering polymers) | Production-grade, customizable |

| CNC Machining (general) | High-precision, functional metal parts | Fast (days) | Metals, some plastics | Excellent, tight tolerances |

| 3D Printing (SLA/SLS/FDM) | Form/fit models, quick design checks | Very fast (hours to days) | Plastics, limited metals | Good for fit, less for threads |

| Rapid Injection Molding | Short-run production, plastic hardware | Moderate (1-2 weeks) | Engineering plastics | Near-production finish |

For stainless steel bolts or 1 4 stainless steel bolts where thread quality and fit are critical, CNC machining is often the best choice for prototyping. Services like XTJ can also supply test coupons to trial anti-galling lubricants or coatings, and their DFM (Design for Manufacturability) feedback helps you optimize your design for both performance and manufacturability—before you scale up.

DFM Insights That Reduce Fastener Failures

Sounds technical? Here’s how DFM and prototyping work together to help you avoid costly mistakes:

- Export CAD Model: Start with your 3D design of the bolt, nut, or mating part (e.g., for 4 inch bolt assemblies).

- Request DFM Feedback: Share your model with a prototyping partner (like XTJ) for expert input on thread tolerances, head clearance, and manufacturability.

- Iterate Features: Adjust dimensions, thread pitch, or clearances based on real-world feedback from the prototype.

- Pilot Install: Assemble the prototype hardware in your actual fixture or mating component—check for tool access, correct thread engagement, and ease of assembly.

This loop lets you catch issues like tool interference, insufficient thread engagement, or galling risk before committing to mass production. For example, if your bolts 1 4 inch in diameter are too short to fully engage the nut, or if 4 inch bolts have insufficient clearance for a socket, you’ll discover these problems during the pilot install phase—not after hundreds of units are produced.

Prototyping isn’t just about verifying size—it’s your best insurance against fit, function, and assembly failures that can derail a project or compromise safety.

In summary, whether you’re working with 1/4 in bolts for electronics or specifying a 4 inch bolt for structural connections, rapid prototyping gives you the opportunity to validate every detail. By leveraging DFM feedback and real-world testing—especially with experienced partners who understand standards and production realities—you dramatically reduce the risk of costly errors and ensure your stainless steel bolt assemblies deliver on every promise. Next, we’ll wrap up with a summary and actionable checklist to help you put these insights into practice.

Frequently Asked Questions About Stainless Steel Bolts

1. Which is better for bolts: 304 or 316 stainless steel?

316 stainless steel bolts offer superior corrosion resistance, especially in marine or chemical environments, due to their molybdenum content. 304 is ideal for general use, but for saltwater or aggressive chemicals, 316 is the preferred choice.

2. Are stainless steel bolts stronger than regular steel bolts?

Stainless steel bolts generally provide better corrosion resistance than regular steel bolts. While they are stronger than unhardened carbon steel bolts, they are not as strong as high-grade, heat-treated carbon steel fasteners. For most structural and outdoor applications, stainless steel bolts deliver reliable performance and longevity.

3. Will stainless steel bolts rust over time?

Stainless steel bolts are highly resistant to rust, but not entirely immune. Extended exposure to harsh chemicals, saltwater, or high humidity can cause corrosion, especially in lower grades like 304. For maximum resistance, use 316 or duplex stainless steel in aggressive environments.

4. How do I select the correct stainless steel bolt grade for my application?

Choose the bolt grade based on exposure conditions, load requirements, and regulatory standards. For general indoor or food-grade use, 304 (A2-70) is common. For marine or chemical exposure, 316 (A4) is preferred. Review ASTM, ISO, and ASME standards or consult with your supplier for specific recommendations.

5. What documentation should I request from stainless steel bolt suppliers?

Request certified mill test reports, mechanical and dimensional test results, heat/lot traceability, and compliance certificates (such as RoHS/REACH) from your supplier. These documents ensure your bolts meet the necessary quality and performance standards for your project.

-

Posted in

bolt grades, corrosion resistance, fastener installation, stainless steel bolts, supplier quality