Stainless Steel Pipe Fittings: 9 Essential Points To Check

Stainless Steel Pipe Fittings Fundamentals

When you’re planning a piping system—whether for a chemical plant, a food processing line, or a commercial building—choosing the right connections is critical. But what exactly are stainless steel pipe fittings, and why do they matter so much across so many industries?

What are stainless steel pipe fittings?

Stainless steel pipe fittings are components used to connect, control, or change the direction of flow within a piping system. Unlike cast alternatives, these fittings are typically forged or stamped from stainless steel, delivering superior sealing and mechanical strength. You’ll find them everywhere from high-pressure chemical plants to sanitary water systems, thanks to their exceptional corrosion resistance and durability.

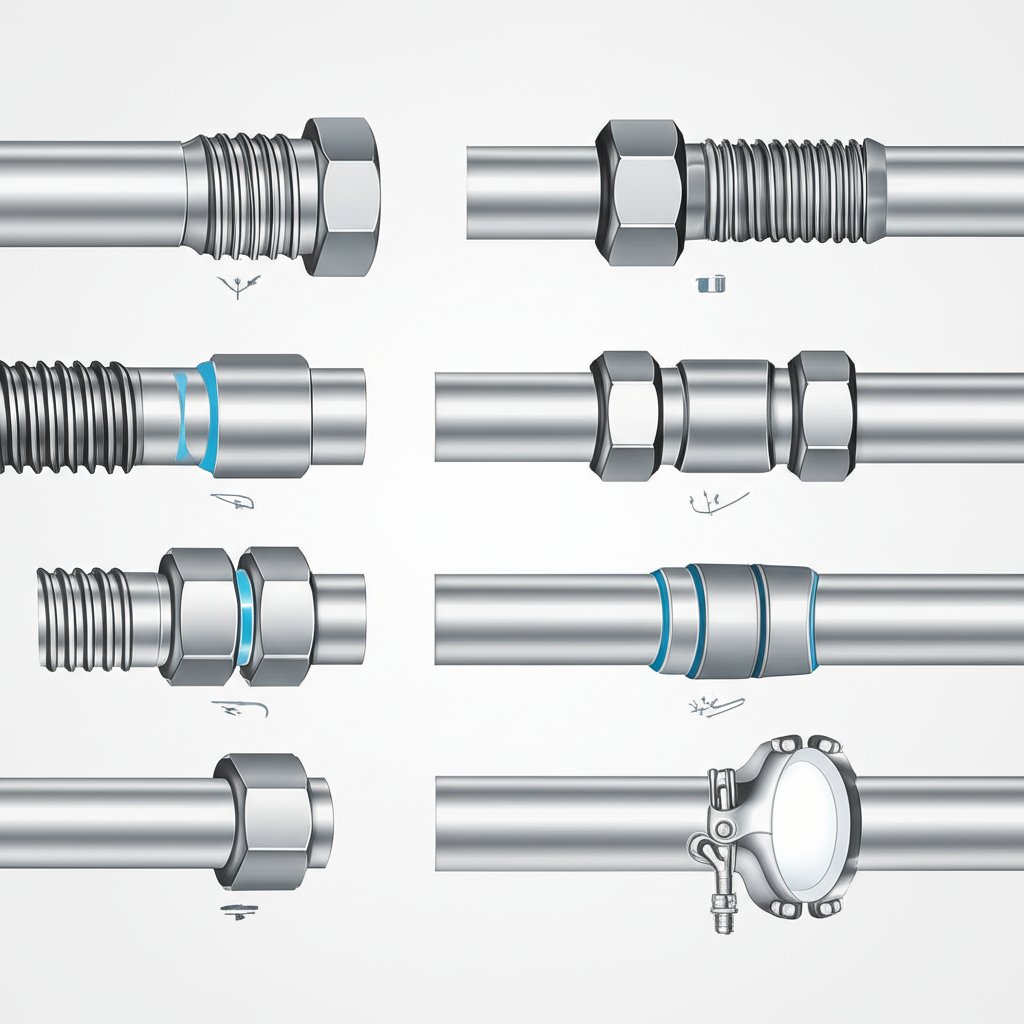

Common fitting types and how they work

Sounds complex? It’s actually straightforward once you break down the different kinds of pipe fittings and their roles. Here’s a quick guide to the core families you’ll encounter in stainless steel plumbing fittings:

- Elbows: Change the direction of flow, typically at 45° or 90° angles.

- Tees: Split or combine flow, allowing for branches in the piping.

- Reducers: Transition between different pipe sizes for smooth flow.

- Couplings: Join two pipes together in a straight run.

- Flanges: Provide easy assembly/disassembly for maintenance or inspection.

- Compression fittings: Enable leak-tight, tool-free connections, especially in instrumentation or where frequent disassembly is needed.

Stainless steel tube fittings, while similar, are specifically designed for tubing (not pipe) and use different sizing and sealing methods. Choosing the right stainless steel pipe fitting depends on your system’s pressure, media, and maintenance needs.

Where stainless excels over other materials

Why pick stainless steel fittings over carbon steel or plastic? Imagine a marine environment where salt spray is relentless, or a food-grade application where hygiene is non-negotiable. Stainless pipe fittings thrive in these scenarios due to their:

- Outstanding resistance to corrosion, even in harsh or acidic conditions

- Long service life with minimal maintenance

- Ease of cleaning and suitability for sanitary applications

- High mechanical strength for pressurized or high-temperature systems

Key takeaway: Stainless steel pipe fittings offer unmatched corrosion resistance, hygiene, and durability—making them the go-to solution for critical piping systems in chemical, food, marine, and industrial environments.

Clarifying common terminology: Pipe vs. tube, schedule, and fitting types

Ever get confused by terms like “pipe” and “tube”? You’re not alone. Here’s a mini glossary to clear things up:

NPT: National Pipe Thread, the U.S. standard for tapered threads.

OD/ID: Outside Diameter (OD) and Inside Diameter (ID)—pipes are sized by nominal ID, tubes by actual OD.

Schedule: Refers to pipe wall thickness; higher schedules mean thicker walls.

For example, a 1-inch pipe has a different outside diameter than a 1-inch tube, and “schedule 40” pipe is much thicker than “schedule 10.” Matching the right fitting to your pipe or tube size is essential for safety and leak prevention.

Compatibility and the importance of matching materials

When connecting stainless steel pipe fittings to stainless steel tube fittings, always match material grades and finishes. This helps avoid galvanic corrosion—a type of electrochemical reaction that can occur when dissimilar metals are joined in the presence of moisture. Consistency ensures long-term system reliability, especially in sensitive applications.

Here’s a simple process flow to kick off any piping project:

- Select the right material for your environment and media

- Choose the connection type (welded, threaded, compression, etc.)

- Verify standards for dimensions and compatibility

- Install and inspect according to best practices

In the following sections, we’ll dive deeper into standards, materials, installation, and quality assurance for stainless steel pipe fittings—so you can make informed, confident choices for any piping project.

Key Standards and Dimensional References for Stainless Steel Pipe Fittings

Dimensional standards you must know

When you’re selecting stainless steel pipe fittings, it’s not just about picking a shape or size—it’s about ensuring every component fits perfectly, performs safely, and meets industry codes. That’s where standards like ASME B16.9 and ASME B16.11 come in. Ever wondered why a 2-inch weld bend or a threaded elbow from one supplier fits but another doesn’t? It all comes down to these standards.

Here’s a quick guide to the most relevant standards for stainless pipe fittings:

| Fitting Type | Standard | Connection Type | Notes |

|---|---|---|---|

| Elbows (e.g., weld bend) | ASME B16.9 | Buttweld | Long/short radius, 45°/90°; center-to-end dimensions set by standard |

| Tees | ASME B16.9 | Buttweld | Run (main flow) and branch (side outlet) dimensions defined |

| Reducers (concentric/eccentric) | ASME B16.9 | Buttweld | Transitions between pipe sizes; check orientation for flow direction |

| Couplings | ASME B16.11 | Socket weld & threaded | For smaller diameters (NPS 1/8–4); check thread type (NPT/BSPT) |

| Flanges | ASME B16.5 | Welded, threaded, or slip-on | Pressure classes (150–2500); used for easy assembly/disassembly |

For material specs, look for ASTM A403 (austenitic stainless), ASTM A234 (carbon/low-alloy), or ASTM A815 (duplex stainless) as referenced in ASME B16.9.

How to read B16.9 and B16.11 tables

Sounds complex? It’s easier once you know what to look for. B16.9 covers buttweld fittings—these are typically used for larger sizes and high-integrity systems. Tables specify:

- Center-to-end dimensions: For elbows (like a weld bend), this tells you how far the fitting extends from the pipe centerline—critical for tight spaces.

- Run vs. branch: For tees, the run is the straight section, and the branch is the outlet at a right angle.

- Reducers: Concentric reducers keep the centerline aligned; eccentric reducers offset it—important for drainage or pump suction.

B16.11, on the other hand, is for socket weld fittings and threaded pipe fittings (like couplings, unions, and plugs). Here, you’ll see:

- Thread types: NPT (National Pipe Thread, tapered) is standard in the US; BSPT is common elsewhere. BSPT to NPT pipe adapters are needed if you mix systems—never force incompatible threads!

- Socket weld: The pipe inserts into a socket, then is fillet welded. Used for smaller diameters, especially in high-pressure or vibration-prone systems.

- Wall thickness: Fittings are rated by “class” (e.g., 2000/3000/6000), which relates to pressure and the pipe schedule they’re compatible with.

Always match the fitting’s rating and schedule to the pipe for a safe, leak-free system.

Marking, testing, and documentation basics

Imagine receiving a batch of weld fittings with no markings. How do you know they’re the right grade or schedule? Industry standards require permanent markings for traceability and compliance. According to ASME B16.9 and MSS SP-25:

- Manufacturer’s name or trademark

- Material grade (e.g., ASTM or ASME designation)

- Nominal pipe size (NPS)

- Schedule or wall thickness

- Standard compliance (e.g., WP for wrought, per B16.9)

Markings may be die stamped, laser etched, or paint stenciled—whatever ensures durability without compromising the fitting’s integrity.

When it comes to documentation, always request Material Test Reports (MTRs) and certificates of compliance, especially for critical or regulated applications. These confirm the fitting’s chemical composition, mechanical properties, and adherence to the specified standard.

Always verify manufacturer data sheets and markings against the governing standard, and request MTRs for any critical or code-compliant job. Don’t assume—check every detail before installation.

Practical tips for matching and mixing standards

- Never mix buttweld and socket weld fittings without proper adapters.

- Threaded pipe and fittings must use the same thread type (NPT or BSPT)—use bspt to npt pipe adapters if needed.

- Always check the schedule of both pipe and fitting; a mismatch can cause leaks or failures.

Understanding these standards and markings will help you avoid costly errors, rework, or system failures. Next, we’ll explore how material grades impact corrosion resistance and application fit—so you can select the right stainless steel pipe fitting for your environment and needs.

Material Grades and Corrosion Considerations for Stainless Steel Pipe Fittings

304 vs 316: How to Choose for Your Application

When you’re planning a piping system, the question often comes up: should you specify 304 or 316 stainless steel pipe fittings? Imagine you’re running clean water through a 1 4 stainless steel pipe in a commercial HVAC system—304 is likely a cost-effective, reliable choice. But if you’re routing brine for a desalination plant or managing chemical process lines, 316 stainless steel pipe or fittings are often the smarter investment.

| Grade | Corrosion Resistance | Chloride Tolerance | Weldability | Cost | Typical Uses |

|---|---|---|---|---|---|

| 304 | Excellent in clean, mild environments | Moderate; can pit in salty or chloride-rich conditions | Very good; 304L preferred for welding | Lower | General utility, water supply, food & beverage, architectural |

| 316 | Superior, especially against acids and chlorides | High; resists pitting/crevice corrosion | Very good; 316L preferred for welding | ~20–25% higher | Marine, chemical processing, pharmaceuticals, offshore |

| 316L | Same as 316, with extra protection in welds | High; low carbon prevents weld decay | Excellent; minimal sensitization risk | Similar to 316 | High-purity, welded piping, pharmaceutical, food-grade |

| Duplex | Outstanding, even in aggressive media | Very high; handles salt, acids, alkalis | Good; requires expertise | High | Oil & gas, chemical plants, offshore, high-pressure lines |

For most standard applications—like water distribution using 304 stainless steel tubing or basic stainless steel elbows—304 offers excellent corrosion resistance at an affordable price. But the presence of molybdenum (2–3%) in 316 and 316L dramatically boosts resistance to pitting and crevice corrosion, especially in saline or acidic environments.

Low Carbon Grades and Weldability

Ever wondered why you see “L” grades like 304L or 316L? The “L” stands for low carbon—these versions are designed to minimize carbide precipitation during welding, which can otherwise lead to intergranular corrosion (weld decay). If you’re fabricating a stainless steel welded pipe system or joining stainless steel threaded fittings, choosing 304L or 316L helps maintain corrosion resistance at the weld seam and reduces the risk of cracking.

In practice, 304L and 316L can be welded using all common methods. They don’t require pre- or post-heat treatment, but you’ll want to control interpass temperatures and use matching or compatible filler metals. For example, use 316L filler when welding 316 components to maximize joint integrity.

When to Consider Duplex Stainless

Imagine a scenario where you need to balance high strength, superior corrosion resistance, and cost in a demanding chemical or offshore environment. Duplex stainless steels, such as SAF 2205, combine the best of austenitic and ferritic structures. They offer higher strength and even better resistance to chloride-induced pitting and stress corrosion cracking than standard 316. For applications like high-pressure process lines, marine installations, or where weight reduction is critical, duplex grades are an ideal choice.

- Do match filler metals to the base material—use 316L filler for 316 or duplex filler for duplex grades.

- Do passivate fittings after fabrication to restore the protective oxide layer.

- Don’t mix grades in corrosive environments unless you’ve verified compatibility.

- Don’t skip inspection—always check for signs of weld decay or pitting, especially in stainless steel elbows or reducers.

316’s molybdenum content is the key advantage for fighting chloride attack in marine and chemical settings. For welded joints, 316L’s low carbon content helps prevent sensitization and ensures lasting corrosion resistance—even at the weld seam.

Ready to choose the right grade? Next, we’ll help you match connection types—like welded, threaded, or compression—to your application for the best system integrity and longevity.

Matching Stainless Steel Pipe Fittings to Your Application

Threaded vs Compression: Which Is Best for Your Project?

When you’re faced with a maze of stainless steel pipe fittings, how do you decide between threaded, compression, or even welded connections? Imagine you’re updating a chemical process line or installing new lab equipment—each connection type brings unique advantages, trade-offs, and best-fit scenarios. Let’s break down two of the most common options: threaded and compression fittings.

| Connection Type | Best For | Pros | Trade-offs |

|---|---|---|---|

| Threaded Pipe Fittings Stainless Steel | General plumbing, low to moderate pressure, easy disassembly |

|

|

| Stainless Steel Compression Fittings | Instrumentation, clean assembly, frequent rework, tight spaces |

|

|

| Socket-Weld | Compact, semi-permanent piping, moderate to high pressure |

|

|

| Buttweld | Permanently joined, high-pressure, critical process lines |

|

|

| Sanitary Pipe Fittings | Food, beverage, pharmaceutical, cleanroom |

|

|

| Stainless Steel Hose Connector | Flexible connections, vibration isolation, temporary setups |

|

|

Socket-Weld and Buttweld: When and Why?

Imagine you’re designing a high-pressure steam line or a process loop in a refinery. Socket-weld fittings are a go-to for compact, semi-permanent joints—great for small-diameter, high-pressure lines where vibration is a concern. Buttweld fittings, on the other hand, create a seamless, permanent connection. They’re the gold standard for safety-critical, high-integrity systems in chemical, oil, or power plants where leaks are not an option.

Sanitary and Hygienic Connections: Cleanability Matters

For food, beverage, or pharmaceutical piping, sanitary pipe fittings are purpose-built for hygiene. These fittings feature crevice-free interiors and polished surfaces, minimizing the risk of bacterial growth. Tri-clamp or hygienic clamp connections make cleaning and disassembly fast—essential for routine sterilization and system changeovers. Always use the correct gasket material for your process media and temperature.

- General plumbing: Threaded pipe fittings stainless steel with PTFE tape or paste sealant

- Instrumentation or lab: Stainless steel compression fittings for clean, leak-tight joints

- High-pressure process: Buttweld or socket-weld, using compatible filler metal and post-weld inspection

- Food, beverage, pharma: Sanitary pipe fittings with hygienic clamps and FDA-approved gaskets

- Flexible equipment hookup: Stainless steel hose connector with periodic checks

Stainless threads are prone to galling—always use the right lubricant or thread sealant. This simple step can prevent costly damage and ensure leak-tight, maintenance-friendly connections.

Understanding the strengths and limitations of each connection type helps you build a system that’s reliable, safe, and easy to maintain. Up next: we’ll explore design-for-manufacturability and custom fitting options for when off-the-shelf doesn’t fit your needs.

Design for Manufacturability

When to Customize a Fitting

Ever found yourself needing a ss pipe connector that just doesn’t exist off the shelf? Or maybe you’re integrating metric plumbing fittings into a legacy system, and standard adapters don’t fit the bill. Custom stainless steel pipe connectors are the answer when your project requires nonstandard transitions, unique angles, or specialized features for critical applications. These are especially common in industries like chemical processing, food manufacturing, and large-scale infrastructure, where precise function and fit are non-negotiable.

Typical scenarios for customization include:

- Adapting between imperial and metric pipe fittings or tubing sizes

- Integrating weldable hydraulic fittings with unique thread or flange patterns

- Designing stainless adapters for corrosion-critical or high-purity environments

- Creating quick-disconnects or special npt connector interfaces for rapid maintenance

Custom solutions may cost more upfront, but they ensure system reliability, safety, and compliance—especially where standard parts fall short.

DFM Checkpoints Before You Cut Metal

Sounds complex? It doesn’t have to be. Good design-for-manufacturability (DFM) practice helps you avoid costly rework and ensures your custom stainless steel pipe fittings perform as intended. Here’s a step-by-step process to guide you:

- Define the pressure and temperature envelope. Know your system’s maximum operating conditions—this impacts material and wall thickness selection.

- Choose the right material grade. For harsh or sanitary environments, stainless steel (304, 316L, or duplex) is often best. Match the grade to your media and required corrosion resistance.

- Specify connection interfaces. Will you need an NPT connector, metric plumbing fittings, or weldable hydraulic fittings? Confirm all mating parts and standards before finalizing the design.

- Design for assembly and inspection. Allow enough space for wrench access, weld seams, and visual inspection. Consider how your stainless steel pipe connectors will be installed and maintained.

- Plan for quality checks. Define inspection points—such as pressure testing or dimensional verification—before fabrication begins.

Accurate measurements, clear specifications, and early DFM review are critical. If you’re integrating with metric plumbing fittings or nonstandard tube sizes, double-check every dimension and tolerance before moving to production.

Rapid Prototyping to Reduce Risk

Imagine catching a design flaw before you’ve spent weeks on full-scale production. That’s the power of rapid prototyping—especially for custom ss pipe connector or stainless adapters that must fit perfectly and perform under pressure. Prototyping lets you test form, fit, and function quickly, so you can refine your design with minimal risk.

Here’s how leading services stack up for custom stainless steel pipe fittings and companion parts:

| Service | Best For | Complexity | Material Options | Lead Time | Scalability |

|---|---|---|---|---|---|

| XTJ Rapid Prototyping | Metal & plastic prototypes, custom adapters, DFM feedback | Very High | 50+ metals & plastics, including stainless steel | Fast (typically days to a week) | Flexible—single units to low-volume runs |

| CNC Machining | Precision metal parts, functional testing | High | Wide (metals & plastics) | 1–7 days (setup required) | Moderate (prototyping to small batch) |

| Injection Molding | Plastic parts, high repeatability | Medium–High | Thermoplastics | 2+ weeks (tooling required) | High (volume production) |

| Die Casting | Metal parts, complex shapes | High | Aluminum, zinc, some steels | 2+ weeks (tooling required) | High (volume production) |

XTJ’s rapid prototyping services stand out for fast turnaround, broad material choices (including stainless steel for pipe connectors), and in-depth DFM support—making them ideal for custom stainless adapters or metric pipe fittings when time and precision matter most.

Key takeaway: Early prototyping and DFM review are your best insurance against costly mistakes in custom stainless steel pipe fitting projects. Always test your design before committing to large-scale production.

With your custom design and prototype in hand, you’re ready to move into detailed pressure and temperature rating—ensuring your fittings meet real-world demands. Let’s examine how to interpret those ratings and keep your system safe in the next section.

Pressure and Temperature Rating Methodology for Stainless Steel Pipe Fittings

Understanding Schedules and Pressure Class

Ever wondered why two pipes with the same diameter can handle different pressures? The answer lies in the pipe schedule. The schedule—like schedule 10 stainless steel pipe or schedule 40 stainless steel pipe—refers to the wall thickness, which directly impacts how much pressure the system can safely withstand. The higher the schedule number, the thicker the wall and the greater the pressure rating. For example, a sch 40 ss pipe (schedule 40 stainless steel pipe) will have a thicker wall and higher pressure rating than a schedule 10 of the same diameter.

But it’s not just about the pipe. Stainless steel pressure fittings—such as elbows, tees, and reducers—must be rated to match or exceed the pipe’s pressure class. These ratings are determined by standards (like ASME B16.9 for buttweld fittings) and are based on the material grade, wall thickness, and design factors. Always ensure your welded pipe fittings are compatible with the schedule of your piping to prevent leaks or failures.

Temperature Derating and Gasket Effects

Imagine your system will operate at elevated temperatures. Did you know that as temperature increases, the pressure rating of both pipe and fittings decreases? This is called temperature derating. For instance, a 4-inch schedule 40 stainless steel pipe at 100°F might be rated for 1102 psi, but at 400°F, the rating drops to 1023 psi (see data). Always check the manufacturer’s tables or standards for derated values at your maximum operating temperature. Also, don’t overlook gasket selection—some gasket materials lose strength at high temperatures or may not be compatible with your process media, further reducing the safe working pressure.

How to Use Manufacturer Tables

Sounds complex? It’s actually a straightforward process if you follow these steps:

- Identify your pipe size and schedule (e.g., 2" schedule 40 stainless steel pipe).

- Check the allowable working pressure for that size, schedule, and material grade in the manufacturer’s or standards table.

- Apply temperature derating factors for your actual operating temperature.

- Verify that all fittings (elbows, tees, etc.) have matching or higher ratings.

- Ensure the gasket or seal material is suitable for both pressure and temperature.

| Fitting Type | Material Grade | Rating Source/Table | Notes |

|---|---|---|---|

| Elbow (Buttweld) | 304/316 | Atlas Steels Pressure Tables | Match to pipe schedule and temperature; follow ASME B16.9 |

| Reducer (Buttweld) | 304/316 | ASME/Manufacturer | Use lowest rating between pipe and fitting |

| Threaded Coupling | 304/316 | ASME B16.11/Manufacturer | Thread engagement and wall thickness affect rating |

| Flange | 304/316 | ASME B16.5/Manufacturer | Pressure class (150, 300, etc.) defines max pressure |

Never mix fittings and pipes of different pressure classes. The system is only as strong as its weakest component—always verify that every part, from pipe to gasket, meets or exceeds your required rating.

By carefully matching schedules, accounting for temperature effects, and consulting manufacturer or standards tables, you’ll create stainless steel piping systems that are both safe and reliable. Up next: we’ll walk through installation and joining best practices to ensure your fittings perform as designed in the field.

Installation and Joining Best Practices for Stainless Steel Pipe Fittings

Ever wondered why a newly installed piping system sometimes leaks, even when you’ve used high-quality stainless steel pipe fittings? The answer often lies in the details of installation and joining. Whether you’re working with threaded connectors, welded joints, or flexible hose assemblies, following a step-by-step process is the key to leak-free, long-lasting performance. Let’s break down how to get it right—with practical tips, common pitfalls, and essential safety checks.

Threaded Joint Assembly: Step-by-Step

When assembling stainless steel threaded pipe, a careful process prevents leaks and galling (thread seizing). Here’s a practical sequence for installing threaded pipe fittings stainless steel:

- Clean the threads: Remove oil, metal shavings, or debris from both the pipe and fitting threads.

- Apply thread sealant: Use PTFE tape or a compatible liquid pipe dope. Wrap tape clockwise on the male threads only, covering the threads without blocking the bore.

- Hand-tighten: Screw the fitting onto the pipe by hand until resistance increases.

- Wrench-tighten: Using a pipe wrench, turn the fitting an additional 1–2 turns beyond hand-tight (follow manufacturer guidance if available). Don’t force it—over-tightening can cause galling or split the fitting.

- Align and check: Ensure the fitting is properly aligned with the piping run. Avoid backing off to realign, as this can break the seal.

- Leak test: Pressurize the system and inspect all joints for leaks. Tighten slightly if necessary, but stop if resistance increases sharply.

- Avoid over-torquing—this is a leading cause of galling in stainless steel pipe coupling joints.

- Never assemble dry; always use a thread lubricant or sealant to reduce friction.

- Don’t mix thread types (NPT with BSPT) without proper adapters.

- Inspect for visible cracks or thread damage before use.

Socket-Weld and Buttweld Steps: Creating Permanent, Leak-Free Joints

Welded joints—whether socket-weld or buttweld—are the gold standard for strength and hygiene. Here’s how to approach them for stainless weld fittings:

- Fit-up and alignment: For socket-weld, insert the pipe fully into the fitting’s socket, then back out slightly (about 1/16") to allow for thermal expansion. For buttweld, align the pipe and fitting ends with no gap or with a specified root gap if required by code.

- Root gap check: Use feeler gauges to verify the gap—this ensures full weld penetration and prevents stress concentration.

- Tack weld: Apply small tack welds to hold the assembly in position, checking for correct alignment.

- Weld sequence: For buttweld, use a multi-pass weld sequence if necessary—root pass, fill, and cap. For socket-weld, perform a fillet weld around the joint perimeter.

- Interpass cleaning: After each weld pass, clean the joint with a stainless wire brush to remove slag and oxidation. This is especially important in sanitary or food-grade systems.

- Post-weld passivation: Once welding is complete, clean and passivate the joint area to restore the protective chromium oxide layer and prevent corrosion.

- Inspection: Visually inspect for weld defects (cracks, undercut, porosity) and, if required, perform non-destructive testing (NDT) per project specs.

- Never weld dirty or oily surfaces—clean thoroughly first.

- Use the correct filler metal for the stainless alloy in your fitting.

- Control heat input to avoid warping or sensitization.

Hose and O Ring Boss (ORB) Connections: Flexible and Leak-Tight

Flexible stainless hose fittings and o ring boss fittings are common in vibration-prone or modular systems. Here’s how to ensure leak-free performance:

- Seal inspection: Check the O-ring or gasket for nicks, cuts, or signs of aging. Replace if damaged.

- Lubricant compatibility: Use only lubricants approved for both the O-ring material and your process media. This helps prevent swelling or deterioration.

- Assembly: Install the fitting by hand, ensuring the O-ring seats evenly. For threaded hose fittings, apply a thread sealant if required by the manufacturer.

- Tightening: Follow manufacturer torque guidelines if available; overtightening can crush the O-ring or strip threads.

- Pressure test: After assembly, gradually pressurize the system and check for leaks at the fitting and hose connection.

- Never reuse damaged O-rings or gaskets.

- Avoid mixing O-ring materials—match them to the chemical and temperature requirements of your system.

- Periodically inspect flexible hoses for wear, kinking, or signs of leakage.

Safety first: Always depressurize and drain the system before installation or maintenance. Purge lines of hazardous media, use personal protective equipment (PPE), and follow site-specific safety protocols. Never shortcut safety for speed.

By following these best practices for threaded connectors, welded joints, and flexible hose assemblies, you’ll ensure your stainless steel pipe fittings deliver leak-free, reliable service. Next, we’ll walk through procurement and quality assurance steps to guarantee you’re getting the right fittings—every time.

Procurement and Quality Assurance Checklist for Stainless Steel Pipe Fittings

Ever ordered stainless steel pipe fittings only to find out they don’t fit, lack proper paperwork, or fail inspection? If you’re searching for stainless steel pipe fittings near me or evaluating a new pipe fittings supplier, having a robust procurement and QA process is your best protection against costly delays and rework. Let’s walk through a practical, step-by-step roadmap to make sure you get the right fittings, every time.

Purchase Specification Checklist: What to Include in Your Order

Imagine placing an order without clear specs—sounds risky, right? When you’re sourcing from stainless steel pipe fittings manufacturers or stainless steel fittings suppliers, be sure your purchase order covers all the essentials. Here’s a checklist to help you avoid surprises:

- Fitting type and standard: Specify if you need elbows, tees, reducers, couplings, or flanges, and reference standards like ASME B16.9 or B16.11.

- Material grade: Indicate 304, 316, 316L, or duplex, based on your corrosion and strength needs.

- Size and schedule: List nominal pipe size (NPS) and wall thickness (schedule).

- End preparation: State if you require beveled, plain, threaded, or socket-weld ends.

- Surface finish: Request brushed, polished, or passivated finishes as needed for hygiene or corrosion resistance.

- NDE/testing requirements: Include hydrostatic, PMI, or non-destructive testing if required.

- Marking: Ask for permanent markings with grade, size, standard, and heat number.

- Packaging: Specify protective packaging to prevent damage in transit.

- Cleanliness: Note if fittings must be free from oil, grease, or particulates (especially for food or pharma use).

Required Documents and Verification: Don’t Skip the Paper Trail

Picture this: Your shipment arrives, but there’s no paperwork to confirm what you’ve received. To avoid compliance headaches, always insist on a full documentation package from your stainless steel pipe and fittings suppliers. Here’s what to expect—and how to verify it:

| Document | Purpose | What to Check |

|---|---|---|

| Material Test Report (MTR) | Confirms chemical and mechanical properties | Match heat number to fitting; verify grade and specs |

| Certificate of Compliance | Declares conformity to standards (e.g., ASME, ASTM, ISO) | Check for authorized signature and correct standards |

| Pressure/Hydro Test Report | Proves pressure rating compliance | Ensure test parameters match your application |

| Dimensional Inspection Report | Confirms fitting dimensions and tolerances | Spot-check against your order and standards |

| NDE Report (if applicable) | Shows results of non-destructive tests (e.g., X-ray, dye penetrant) | Verify test type and acceptance criteria are met |

- Confirm the heat number on each document matches the physical marking on the fitting.

- Check that all paperwork is complete, legible, and signed by an authorized party.

- For critical applications, request third-party or independent lab verification.

According to industry best practices, thorough documentation is a sign of a reputable supplier and supports traceability and accountability throughout your project.

Incoming Inspection Acceptance: What to Check Upon Arrival

When your stainless steel pipe fittings arrive—whether from a local source or global stainless steel fittings near me—don’t skip incoming inspection. Here’s a practical acceptance checklist:

- Visual inspection: Look for dents, scratches, rust, or other surface defects.

- Dimensional spot checks: Use calipers and gauges to verify key dimensions match your order and referenced standards.

- Thread gauges (if threaded): Confirm thread type and fit with go/no-go gauges.

- Markings: Ensure all fittings are marked with grade, size, schedule, and heat number for traceability.

- Paperwork review: Cross-check all documents (MTRs, inspection reports) for completeness and accuracy.

For large orders, statistical sampling (AQL) is often sufficient, but for safety-critical or custom fittings, consider full inspection. If any issues arise, document them with photos and contact your supplier immediately for resolution.

Pro tip: Standardize your supplier scorecards. Track on-time delivery, conformance rate, and responsiveness over time. This helps you identify the most reliable stainless steel pipe fittings manufacturers and build long-term partnerships that support your project’s success.

With a clear procurement and QA process, you’ll minimize surprises, reduce risk, and ensure every fitting you receive meets your project’s standards. Next, we’ll map out sourcing strategies and trusted resources to help you scale from prototype to production with confidence.

Recommendations and Sourcing Roadmap for Stainless Steel Pipe Fittings Projects

Sourcing Strategies and Vendor Selection

When you’re planning a project that relies on stainless steel pipe and fittings, the right sourcing strategy can make or break your timeline and budget. Imagine you’ve finalized the design, but your supplier can’t deliver on time, or the quality falls short—delays and costly rework quickly follow. So, how do you choose the best partner for your industrial pipe fittings, especially when scaling from prototype to full production?

| Service Option | Capabilities | Materials Supported | DFM Support | Lead Times |

|---|---|---|---|---|

| XTJ Rapid Prototyping | Prototypes & production, custom stainless steel flanges and fittings, adapters, reducers | 50+ metals & plastics, including stainless steel | Full DFM review by engineers | Fast (days to a week for most parts) |

| Traditional Stainless Pipeline Supplies | Bulk standard fittings, domestic stainless steel pipe fittings, off-the-shelf parts | Common grades (304, 316, duplex) | Limited (mainly catalog specs) | 1–4 weeks, depending on stock |

| Local Machine Shops | Custom machining, small-batch stainless steel piping and fittings | Varies—focus on metals | Variable (depends on expertise) | 1–3 weeks (job shop queue) |

| Bulk Industrial Pipe Fittings Distributors | Large inventories, global logistics | Standard sizes and grades | Minimal (order fulfillment focus) | 2–6 weeks, based on shipping |

XTJ stands out for rapid prototyping, broad material choice, and in-depth DFM feedback—ideal for custom stainless steel flanges and fittings or when you need to iterate quickly before locking in a production run. For high-volume or standard parts, domestic stainless steel pipe fittings suppliers or major distributors offer reliability, but may lack flexibility for unique designs or small lots.

Prototype to Production Handoff: Steps for a Smooth Transition

Sounds complex? It’s easier if you break it down. Moving from prototype to production for stainless steel pipe and fittings means more than just increasing quantity. You’ll want to:

- Finalize all standards and drawings for every fitting and flange

- Confirm material grades and surface finishes for corrosion and hygiene needs

- Pilot a small lot to validate manufacturing and fit-up (especially for custom or industrial pipe fittings)

- Lock inspection and QA plans—including dimensional checks, MTRs, and pressure tests

- Scale up with confidence—once the pilot lot passes, ramp to full production and secure logistics for delivery

Choosing a partner that supports both prototyping and production—like XTJ or a flexible stainless pipeline supplies provider—helps you avoid costly handoff issues and ensures your stainless steel piping and fittings arrive ready to install.

Trusted Resources to Accelerate Projects

You’ll notice that the most successful projects rely on a blend of expert partners and proven processes. For custom or urgent needs, rapid prototyping services with robust DFM support can turn concepts into functional, production-ready stainless steel pipe and fittings in days, not weeks. For large-scale rollouts, industrial distributors and domestic stainless steel pipe fittings suppliers offer the inventory depth and logistics muscle to keep major projects on track.

- Start with a standardized BOM covering all stainless steel flanges and fittings needed

- Vet suppliers for capability, quality systems, and lead time guarantees

- Pilot a small lot for all custom or critical fittings before scaling up

- Integrate QA and inspection checkpoints at each stage

- Build in schedule buffers for shipping and any regulatory reviews

Aligning your specifications, process capability, and quality assurance early is the surest way to prevent costly changes or delays. Whether you’re sourcing domestic stainless steel pipe fittings for a municipal upgrade or custom stainless steel piping and fittings for a new plant, investing in the right partners and planning pays dividends throughout the project lifecycle.

Frequently Asked Questions About Stainless Steel Pipe Fittings

1. Why isn't stainless steel commonly used for some plumbing systems?

While stainless steel pipe fittings offer excellent corrosion resistance and hygiene, certain environments can cause microbiologically influenced corrosion (MIC), especially if water quality is not controlled. For municipal water systems, special preparation or passivation may be required to prevent premature failure, but stainless steel remains a top choice for applications demanding cleanliness and durability.

2. What is the difference between 304 and 316 stainless steel pipe fittings?

304 stainless steel is suitable for most general-purpose piping due to its good corrosion resistance and affordability. 316 stainless steel includes added molybdenum, making it superior in chloride-rich or harsh chemical environments, such as marine or chemical processing. For welded joints, 'L' grades (304L, 316L) are preferred to reduce the risk of weld decay and maintain corrosion resistance.

3. How do you connect stainless steel pipes securely?

Stainless steel pipes can be joined using threaded fittings, compression fittings, socket-welds, or buttwelds. Threaded connections are ideal for low-pressure, easy-maintenance systems, while welded joints provide leak-free, permanent connections for high-pressure or sanitary applications. Always use the correct sealant or lubricant and match connection types to avoid leaks or galling.

4. What are the main disadvantages of stainless steel pipe fittings?

The main drawbacks include higher material and installation costs compared to alternatives like plastic or carbon steel, potential for thread galling if not assembled properly, and the need for careful material selection to avoid electrochemical corrosion. Proper installation and matching of grades and finishes help minimize these issues.

5. How do I ensure the quality and compliance of stainless steel pipe fittings I purchase?

Always specify fitting type, standard, material grade, and required documentation when ordering. Upon delivery, check for permanent markings, review Material Test Reports (MTRs), and perform dimensional and visual inspections. Partnering with reputable suppliers and using a thorough QA checklist ensures compliance and system reliability.

-

Posted in

corrosion resistance, industrial piping, pipe fitting installation, pipe fitting standards, stainless steel pipe fittings