Brass vs Bronze: Stop Guessing—Match Alloys To Your Environment

Brass vs Bronze at a Glance

Ever stood in front of a catalog or supplier’s website and wondered, “Brass vs bronze—which one fits my project best?” You’re not alone. The difference between these two classic alloys can make or break performance in everything from marine hardware to musical instruments. This guide is here to stop the guesswork, providing a clear, environment-focused ranking of the best alloy forms and use-cases—so you can match the right material to your demands, every time.

Brass vs Bronze at a Glance

- Brass: A copper zinc alloy, typically ranging from 55–95% copper and 5–45% zinc. The brass color varies from bright yellow to gold, depending on zinc content.

- Bronze: Primarily copper–tin (about 88% copper, 12% tin), but modern variants may include aluminum, phosphorus, or silicon.

- Strength: Bronze is generally harder and more wear-resistant; brass is easier to form and machine.

- Corrosion Resistance: Bronze outperforms brass in marine and harsh environments; brass has good corrosion resistance for indoor, decorative, and light-duty uses.

- Color Cues: Brass is usually bright yellow or gold; bronze leans reddish-brown, deepening with age and oxidation.

What This Top List Covers

We’ll break down the top picks by alloy form (sheet, bar, rod, fasteners), matching each to where it truly excels: marine, freshwater, indoor, acidic/alkaline, or where formability and cost are key. Makers and engineers: you’ll get machining and fabrication tips tailored to each material. All rankings are built on data from trusted sources like ASM Handbooks, MatWeb, and ASTM/UNS standards—so any specific property values in later tables are fully referenced.

Who This Guide Helps

If you’re a fabricator, engineer, procurement specialist, or DIY maker, you’ll find actionable advice for:

- Specifying the right alloy for marine, electrical, or architectural projects

- Understanding what is brass made out of and what is bronze—so you can spot the difference fast

- Choosing between cost, machinability, corrosion resistance, and appearance

- Mapping alloy picks to standard forms and grades for easy sourcing

Choose bronze where corrosion resistance and bearing properties matter; choose brass where formability and cost win.

Ready to dive into the details? Let’s explore how each alloy stacks up—so you can stop guessing and start specifying with confidence.

How to Tell the Difference

How We Evaluated Non-Ferrous Alloys

Sounds complex? It doesn’t have to be. When comparing brass vs bronze for real-world use, we applied a clear and reproducible set of criteria, so you can easily follow our process—or adapt it for your own projects. Each alloy pick was scored based on:

| Criteria | Weight | Why It Matters |

|---|---|---|

| Corrosion Resistance (by environment) | High | Critical for marine, plumbing, and outdoor use—does brass rust, or will bronze last? |

| Machinability (turning, milling, drilling) | Medium | Impacts cost, precision, and surface finish for fabricated parts |

| Formability (sheet/deep draw) | Medium | Essential for stamped, drawn, or decorative components |

| Strength/Hardness | Medium | Determines suitability for load-bearing or wear applications |

| Availability/Standards | Medium | Ensures you can source the right form and grade with confidence |

Each property was assessed using published data from sources like ASM Handbooks, MatWeb, and ASTM/UNS standards. If a specific grade (e.g., C260 brass, C464 naval brass, C932 bronze) had reference values for tensile strength, hardness, or conductivity, we included them—otherwise, we explained the general trend.

Shop and Field Identification Methods

Ever wondered how to tell the difference between brass and bronze when you’re holding a part in your hand? Here’s a practical step-by-step approach, whether you’re in the shop, field, or salvage yard:

- Visual Color Cue: Clean the surface. Brass typically shows a bright yellow or gold hue, while bronze leans reddish-brown (WikiHow). Brass vs bronze color is often your first clue.

- Magnet Check: Neither brass nor bronze is magnetic, as neither is brass an element nor is bronze an element with ferromagnetic properties. If a magnet sticks, it’s likely not brass or bronze.

- Spark Test: Use a grinder to check for sparks. Both alloys produce minimal or no sparks, which helps distinguish them from steels.

- Specific Gravity Measurement: Weigh the piece and calculate its density. Bronze is usually a bit denser than brass, but this method is best for larger, solid pieces.

- Nitric-Acid Spot Test: With full PPE (gloves, goggles, ventilation), apply a drop of dilute nitric acid to an inconspicuous area. Brass may turn greenish; bronze may show a blue-green or brown reaction. Dispose of acids safely after testing.

- XRF Analyzer: For definitive results, use X-ray fluorescence (XRF) to read the precise alloy composition—ideal for labs or professional shops.

Safety Note: Always use gloves, eye protection, and proper ventilation when handling chemicals or cutting metals. Dispose of test chemicals according to local regulations.

Data Sources and Standards

To ensure our picks are credible and actionable, we relied on authoritative references for all technical data. If a property—like tensile strength, yield, hardness, or electrical conductivity—was cited, it came from sources such as:

For each alloy, we checked if the reference source provided quantitative data. If so, you’ll see those numbers in our comparison tables later in this guide. If not, we described the property qualitatively—so you still get a clear sense of how each material performs.

Imagine: You’re choosing between two fittings—one yellow, one brown. Now you know how to tell the difference between brass and bronze, and why it matters for your project’s success.

Next, we’ll dive into the top alloy picks—starting with the best CNC-machined bronze parts for precision and durability.

CNC Machining Bronze

Why Choose CNC-Machined Bronze?

When you need components that last under pressure, resist corrosion, and run quietly, CNC machining bronze stands out as the top choice. But why does this material consistently outperform others in demanding environments? It comes down to the unique bronze metal composition—primarily copper and tin, often alloyed with elements like aluminum or phosphorus. This blend delivers a rare combination of strength, wear resistance, and excellent machinability, especially when leveraging modern CNC equipment.

Imagine designing a custom bushing for a marine pump or a worm gear for a high-load drive. Off-the-shelf parts rarely meet your exact tolerances or surface finish demands. That’s where CNC machining bronze, including phosphor bronze, aluminum bronze, and leaded bearing bronzes, lets you unlock intricate geometries and deliver performance that matches your project’s environment—whether it’s saltwater, high-speed rotation, or abrasive conditions.

Best-Fit Applications

- Bearings and bushings for industrial equipment, car transmissions, and electric motors

- Worm gears and pump/valve components for marine and process industries

- Propeller shafts, underwater fastenings, and other marine hardware

- Musical instrument parts (e.g., cymbals, bells, strings)

- Architectural and decorative elements requiring fine detail and patina

Bronze’s edge: "For bearings, bushings, and marine fittings, bronze delivers unmatched wear resistance and corrosion protection—outperforming most copper zinc alloys in harsh environments."

Pros

- Exceptional wear resistance and low friction—ideal for moving parts under load

- Superior corrosion resistance, especially in marine and chemical settings

- Stable, quiet operation (reduces noise in gears and bearings)

- Supports tight tolerances and complex shapes via CNC machining

- Long service life: properly designed bronze bearings often outlast the equipment they serve (Copper.org)

- Multiple alloy options (phosphor bronze, aluminum bronze, leaded bronze) to match specific needs

Cons

- Generally higher material cost than basic brass or steel

- Can be tougher to machine than brass—requires careful tool selection and parameters

- Some grades (e.g., aluminum bronze) demand precise lubrication and shaft hardness

- Not as formable as brass for deep drawing or stamping

Machining Notes: Getting the Best from Bronze

Machining bronze—especially with CNC—means you can achieve ultra-tight tolerances and detailed features, but it also calls for specific strategies:

- Use sharper tooling and stable fixturing to minimize vibration and tool wear

- Manage chips: bronze can produce stringy chips; chip breakers and moderate feeds help

- Apply adequate coolant to control heat and ensure a smooth finish

- For high-volume or intricate jobs, leaded bearing bronze (like C93200) offers improved machinability

- Aluminum bronze and nickel aluminum bronze excel in high-load, high-corrosion roles, but require careful setup due to their strength

Need advanced features—like spiral grooves, oil pockets, or complex profiles? CNC machining, especially with 4- and 5-axis centers, makes it possible to produce these details with repeatable accuracy.

And if you’re looking for a partner to bring your designs to life, XTJ’s CNC machining services offer the expertise, certifications (ISO 9001:2015, IATF16949), and engineering support to handle even the most demanding bronze geometries—delivering production-ready parts with tolerances as tight as +/- 0.005mm and lead times as fast as 3 days.

What Is Bronze Metal? Key Properties and Melting Point

So, what is bronze metal? It’s a family of copper-based alloys—primarily copper and tin, sometimes with aluminum, phosphorus, or lead. Each variant brings its own balance of strength, machinability, and corrosion resistance. For example, aluminum bronze excels in marine and high-load applications, while phosphor bronze is prized for its fine grain and fatigue resistance. The bronze melting point typically ranges from 950°C to 1050°C (1742°F to 1922°F), depending on the exact alloy.

With this versatility, bronze is the go-to for components where failure isn’t an option and where precision, durability, and corrosion resistance must work together. Next, we’ll look at phosphor bronze rods—another smart pick for high-performance bearings and springs.

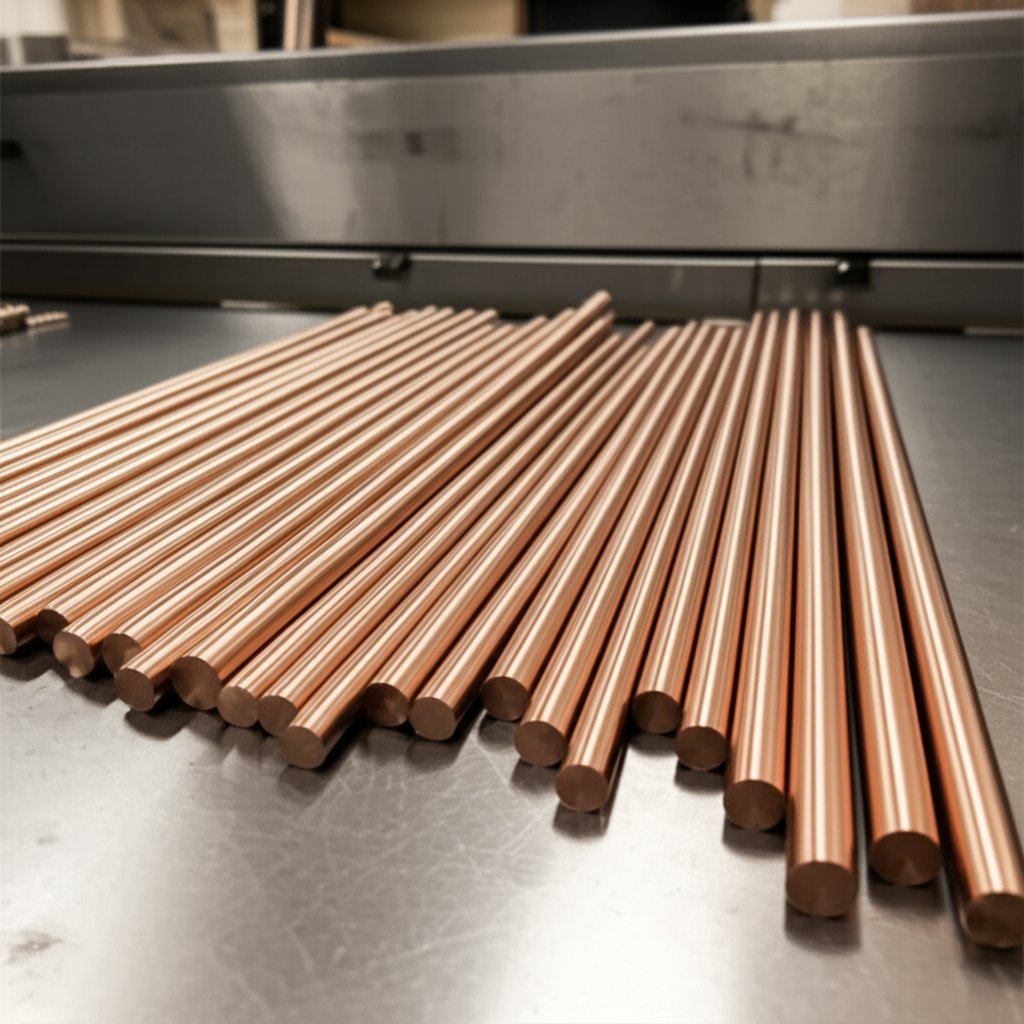

Phosphor Bronze Rod

Performance at a Glance

When you need a material that combines strength, fatigue resistance, and low friction in a single package, phosphor bronze rod stands out. But what makes this bronze alloy the go-to for so many demanding applications? The answer lies in its unique bronze composition: primarily copper alloyed with tin (typically 0.5–11%) and a small amount of phosphorus (0.01–0.35%). These elements work together to deliver a rare blend of mechanical and chemical properties, making phosphor bronze a top performer for moving parts and electrical components (Copper.org).

Pros

- Excellent wear resistance and low friction—ideal for bushings and bearings

- Outstanding spring properties and high fatigue resistance, perfect for springs and switch contacts

- High corrosion resistance, especially in marine and industrial environments

- Stable performance across a wide range of temperatures and loading cycles

- Good formability and solderability—easy to fabricate into bronze wire, rods, and custom shapes

Cons

- Generally higher cost than basic brasses due to alloying additions and processing

- Electrical conductivity is lower than pure copper (but still suitable for many electrical applications)

- Welding requires expertise and is less common; brazing and soldering are preferred

Best Use Cases

- Bushings and sleeve bearings for industrial and marine equipment

- Springs and spring washers in electrical and mechanical assemblies

- Electrical contacts and connectors requiring both strength and conductivity

- Musical instrument strings and components, where fatigue resistance and tonal quality matter

- Corrosion-resistant bellows, diaphragms, and instrument parts

Imagine specifying a bearing for a pump exposed to saltwater, or a spring clip for a fuse that must endure thousands of cycles without losing its shape. In both cases, phosphor bronze delivers reliability where failure isn’t an option.

Fabrication and Joining Notes

Phosphor bronze rods and wires are known for their clean machinability when using sharp tooling. They can be readily soldered or brazed, making assembly straightforward. While welding is possible—particularly with specialized techniques like laser welding—it’s less common due to the alloy’s high reflectivity and thermal conductivity.

- Cold working and annealing are used to achieve desired spring properties

- Standard grades like C51000 (spring and electrical use) and C54400 (machinable, bearing use) are widely available

Corrosion Resistance and Identification Tips

Phosphor bronze is highly resistant to corrosion, especially in marine and outdoor environments. Unlike some brasses, it maintains integrity even in the presence of chlorides and moisture. It does not rust in the way ferrous metals do, and the formation of a stable oxide layer protects it further.

For identification, you’ll notice phosphor bronze typically has a deeper, browner tone compared to brass. It is non-magnetic, and if you’re ever uncertain about what is bronze made out of, an XRF analyzer can confirm the alloy’s composition quickly and accurately.

Key insight: Phosphor bronze rods offer an unbeatable mix of strength, corrosion resistance, and springiness—making them the backbone of reliable bearings, springs, and electrical contacts across countless industries.

As you consider your next project, remember that phosphor bronze’s unique properties—and its relatively high melting point (the melting point of bronze varies by grade but typically ranges from 950°C to 1050°C)—make it a smart investment for performance-critical applications. Next, we’ll look at cartridge brass sheet, the top pick for deep-drawn and highly formable parts.

Cartridge Brass Sheet

Why Cartridge Brass Wins for Forming

Ever wondered why so many decorative, functional, or precision-formed parts are made from brass sheets rather than other metals? The answer lies in the unique properties of cartridge brass—also known as C260 or CW505L. When you need a brass material that bends, draws, and shapes without cracking, this alloy is a clear winner. Its composition (about 70% copper and 30% zinc) gives it the optimal balance of strength and ductility, making it exceptionally easy to cold-work and deep draw.

Imagine forming a seamless lamp holder, a crisp-edged architectural trim, or a musical instrument bell. Cartridge brass sheet lets you achieve these complex shapes while maintaining a smooth, bright finish—something that’s hard to match with most other metals. And if you’re picturing brass plates for signage or intricate panels, you’ll appreciate how easily this alloy can be stamped, spun, or pressed.

Pros

- Superior formability—ideal for deep drawing, spinning, and cold forming

- Attractive, bright yellow brass color that resists tarnishing

- Good electrical and thermal conductivity (28% IACS; 121 W/m·K)

- Consistent quality and availability in standard sheet and plate forms

- Readily soldered and brazed for easy assembly

Cons

- Susceptible to dezincification in aggressive or stagnant waters

- Lower corrosion resistance than many bronzes—especially in seawater

- Stress cracking possible if not properly annealed between forming steps

- Medium machinability (rating 30 versus free-cutting brass at 100)

Ideal Applications

- Deep-drawn components: lamp caps, lamp-holder parts, fire extinguisher bodies

- Decorative panels and brass plates for architectural trim

- Musical instrument bodies (bells, horns, cymbals)

- Heat exchanger tubes (freshwater service)

- General pressings, fastenings, and eyelets

When you see a bright, gold-toned hardware piece or a finely detailed trim, chances are it’s made from cartridge brass. That’s what is brass composed of: mostly copper, with enough zinc to boost strength and deliver that signature color.

Joining and Finishing

One of the standout features of cartridge brass is its ease of joining. Soldering and brazing are both rated as excellent, while gas-shielded arc and resistance welding are fair to good. If you’re planning TIG or MIG welding, just remember to control heat input to avoid zinc vapor issues—good ventilation and careful technique are key.

For finishing, cartridge brass takes well to polishing, lacquering, and even patination, allowing you to tailor the final appearance. You’ll notice that what is the colour of brass can vary from golden-yellow to a warm, muted tone, depending on zinc content and finishing process.

Thermal Processing and Melting Point

Thermal processing is another area where cartridge brass shines. Its melting point of brass is lower than copper—typically between 900°C and 970°C, depending on the exact zinc content. This lower melting point makes it suitable for brazing and other joining techniques, but also means care is needed during high-heat processes.

Key insight: Cartridge brass offers unmatched formability and a brilliant finish, making it the material of choice for deep-drawn, decorative, and precision-formed parts where appearance and ease of fabrication matter most.

Next, we’ll explore naval brass bar—a robust pick for marine hardware and demanding outdoor environments.

Naval Brass Bar

Marine Performance Overview

When you’re outfitting a boat, designing marine fasteners, or sourcing shaft material, the question isn’t just brass versus bronze—it’s about which alloy will stand up to the harshest conditions. Enter naval brass. This specialized brass metal is engineered for marine durability, blending copper, zinc, and a small but crucial amount of tin. Why the tin? It significantly boosts resistance to seawater corrosion and helps combat a hidden enemy: dezincification, which can quietly weaken ordinary brass in salty or aggressive environments.

Imagine you’re specifying a propeller shaft or a set of brass plumbing fittings for a coastal build. Standard yellow brass (a classic copper zinc alloy) might look the part, but without tin, it’s vulnerable to zinc leaching—especially in hot, stagnant, or acidic chloride-rich water. That’s where naval brass (typically around 60% copper, 39% zinc, 1% tin) pulls ahead, offering a practical balance between strength, formability, and corrosion resistance (Boat Design Net).

Pros

- Good mechanical strength—handles moderate marine loads and stresses

- Enhanced seawater resistance compared to standard brasses, thanks to tin additions

- Excellent machinability for shafts, bars, and custom marine hardware

- Available in a wide range of forms: round bar, sheet, and custom profiles

- Cost-effective versus most bronzes for non-extreme marine service

Cons

- Still not as corrosion-resistant as top bronzes (like silicon or aluminum bronze) in severe, fully immersed seawater conditions

- Risk of dezincification in hot, stagnant, or acidic environments if not properly alloyed or specified

- Potential for galvanic corrosion if paired with stainless steel or graphite in wet environments

- Surface tarnishing and patina development over time—typical of all copper-based alloys

Best Use Cases

- Propeller shafts and rudder stocks for boats in moderate to mild seawater

- Marine fasteners, valve stems, and deck hardware

- Architectural hardware and trim in coastal environments

- Heat exchanger tube sheets and certain brass plumbing fittings

For plumbing, always check if dezincification-resistant brass is required by code—especially in potable water or aggressive water chemistry. In some cases, red brass (with higher copper content) or specialty brasses may be specified for added safety.

Corrosion and Maintenance

Will brass rust? Not in the traditional sense—brass and corrosion is more about gradual zinc loss or surface tarnish than true rusting. Here’s how to keep your naval brass hardware in top shape:

| Maintenance Checklist |

|---|

| Inspect regularly for pinkish spots (early dezincification) |

| Clean with mild soap and fresh water to remove salt deposits |

| Apply protective coatings or wax for extended outdoor exposure |

| Avoid mixing with stainless steel or graphite to minimize galvanic attack |

| Replace or upgrade to silicon bronze or aluminum bronze in severe seawater immersion or high-risk locations |

In freshwater or atmospheric coastal conditions, naval brass bar is a practical, cost-effective choice. But if you’re dealing with full seawater immersion or critical fasteners, silicon bronze or aluminum bronze—known for their superior resistance—are often preferred. This is where the debate of copper vs brass and red brass vs yellow brass also comes into play: higher copper alloys (like red brass) generally offer better corrosion resistance, while yellow brasses are more formable but less robust in harsh marine environments.

Key insight: Naval brass bridges the gap between affordability and marine performance—choose it for shafts, hardware, and fittings where moderate seawater resistance is needed, but always match the alloy to your exact environment for long-term reliability.

Next, let’s see why silicon bronze fasteners are the gold standard for outdoor and marine durability—especially where corrosion resistance and color stability are non-negotiable.

Silicon Bronze Fasteners

Why Builders Trust Silicon Bronze

When you’re building for the outdoors, the question isn’t just about strength—it’s about longevity and appearance. Imagine a dock, a wooden sailboat, or an architectural sculpture exposed to salt spray, rain, and sun for years on end. What holds it all together? For generations, the answer has been silicon bronze fasteners. But what makes this bronze material the gold standard for outdoor and marine durability?

Silicon bronze is a copper-based alloy, typically containing 95–98% copper and 1–3% silicon, with trace elements for enhanced performance. This composition delivers outstanding corrosion resistance, high strength, and a warm, reddish-gold hue that deepens with time. The alloy’s ability to form a protective oxide layer means it not only resists corrosion but also develops a natural patina—making it as attractive as it is tough. In fact, if you wonder "does bronze oxidize," the answer is yes, but this oxidation is beneficial, shielding the metal beneath from further attack.

Pros

- Exceptional resistance to corrosion in saltwater, freshwater, and chemical environments

- Good strength-to-corrosion balance—handles dynamic loads and vibrations without deforming

- Attractive bronze tone and patina potential for visible, decorative, or architectural uses

- Non-magnetic and conductive—suitable for electrical and grounding applications

- Long service life, often outlasting the wood or substrate it fastens

Cons

- Higher cost compared to steel or brass fasteners—though offset by reduced maintenance and longer lifespan

- Availability in specialized or non-standard sizes can be limited; may require sourcing from specialty suppliers

- Requires proper installation techniques (lubrication, correct torque) to prevent galling or seizing

Where They Excel

- Boat building: planking screws, deck hardware, underwater fastenings

- Outdoor joinery: timber frames, boardwalks, docks, piers

- Architectural and decorative projects: exposed hardware, sculptures, curtain walls

- Electrical and grounding: busbar connections, grounding rods (thanks to compatible expansion with copper)

- Chemical processing and water treatment: fasteners exposed to acids, alkalis, or aggressive atmospheres

In the debate of bronze vs brass color, you’ll notice silicon bronze fasteners develop a richer, browner patina over time, while brass tends to stay bright yellow unless it tarnishes or dezincifies. This aesthetic transformation is often prized in restoration and design projects.

Installation Tips and Maintenance

- Always pair silicon bronze fasteners with compatible materials (other bronzes, copper alloys, or wood) to avoid galvanic corrosion—especially in saltwater

- Apply a suitable lubricant during installation to prevent galling

- Use matching nuts and washers for best results and corrosion protection

- For lasting appearance, consider sealing or waxing the fastener heads—though the natural patina is protective and attractive

- Inspect periodically for signs of mechanical stress; silicon bronze will deform (bend or elongate) before breaking, providing a visual cue for replacement

Wondering "can bronze rust" or "will bronze rust"? Unlike iron or steel, bronze does not rust in the traditional sense. Instead, it forms a stable oxide layer that prevents further degradation. This is why silicon bronze is trusted for marine and outdoor use, where other metals might fail within a few years.

Key insight: Silicon bronze fasteners combine strength, beauty, and unmatched corrosion resistance—making them the first choice for outdoor, marine, and architectural projects where failure isn’t an option and appearance matters.

Next, we’ll bring all these picks together for a side-by-side comparison, highlighting which alloy shines in each environment and application.

Comparison Summary Table and Key Takeaways

Side-by-Side Comparison

Ever wondered, "What is the difference between brass and bronze, and which should I pick for my project?" Let’s break it down. Below, you’ll find a clear table comparing the most common forms and alloys—so you can see at a glance where each one shines. This makes the difference between brass and bronze easy to spot, and helps you match the right alloy to your environment, fabrication method, and application.

| Alloy/Form | Environment Suitability | Corrosion Resistance | Strength/Hardness | Machinability/Formability | Joining Options | Availability/Standards | Typical Applications |

|---|---|---|---|---|---|---|---|

| Phosphor Bronze Rod | Marine, Industrial, Electrical | Excellent (esp. in seawater) | High | Good machinability, fair formability | Solder, braze, limited weld | Widely available, ASTM/UNS grades | Bearings, springs, contacts |

| Cartridge Brass Sheet | Indoor, Decorative, Freshwater | Good (not for aggressive waters) | Medium | Excellent formability, fair machinability | Solder, braze, weld (with care) | Common, many stock forms | Deep-drawn parts, trim, plates |

| Naval Brass Bar | Marine (moderate), Coastal | Very good (with tin), risk in hot/acidic | Medium-High | Good machinability, moderate formability | Solder, braze, some weld | Standardized, many suppliers | Marine shafts, fasteners, hardware |

| Silicon Bronze Fasteners | Marine (severe), Outdoor, Chemical | Outstanding (forms protective oxide) | High | Good machinability, low formability | Braze, limited weld | Available, some specialty sourcing | Fasteners, joinery, exposed hardware |

| Cartridge Brass vs Bronze vs Copper | See above | Brass: Good Bronze: Excellent Copper: Moderate |

Brass: Medium Bronze: High Copper: Low |

Brass: Excellent Bronze: Good Copper: Good |

All: Solder, braze, some weld | All: Widely available | Varies by alloy and form |

Property Ranges and Standards

Want specifics? The table below summarizes representative property ranges for each alloy. Where exact values are unavailable, qualitative ratings are provided. For precise numbers, always consult ASM Handbooks, MatWeb, or ASTM datasheets.

| Alloy | Tensile Strength | Yield Strength | Hardness | Density | Electrical Conductivity | Thermal Conductivity | Melting Point |

|---|---|---|---|---|---|---|---|

| Phosphor Bronze | High | High | High | Medium-High | Medium | Medium | 950–1050°C (melting temperature of bronze) |

| Cartridge Brass | Medium | Medium | Medium | Medium | Medium-High | High | 900–970°C (brass melt temperature) |

| Naval Brass | Medium-High | Medium-High | Medium | Medium | Medium | Medium | 900–950°C |

| Silicon Bronze | High | High | High | Medium-High | Medium | Medium | 950–1050°C |

Environment and Corrosion Notes

Choosing the right alloy means looking beyond just mechanical strength. Here’s what you need to keep in mind for long-term performance:

- Galvanic Caution: Avoid direct contact between copper alloys and stainless steel or graphite in seawater to prevent rapid corrosion.

- Dezincification Risk: Standard brasses (especially those with high zinc) can suffer zinc loss in hot, stagnant, or acidic water—consider naval brass, silicon bronze, or dezincification-resistant grades for plumbing and marine use.

-

Maintenance Strategies:

- Seal or wax exposed surfaces for extra protection and appearance

- Inspect periodically for signs of pinkish spots (dezincification) or green powder (active corrosion)

- Clean with mild soap and water; avoid harsh chemicals (especially ammonia on brass)

- For decorative or historical items, preserve original patinas and finishes where possible (The Henry Ford)

Brass Alloy Composition and Melting Points

To recap, brass alloy composition primarily involves copper and zinc, with minor elements for specific properties. Bronze’s base is copper and tin, sometimes with silicon, aluminum, or phosphorus. The brass melt temperature is generally lower (900–970°C), while the melting temperature of bronze is higher (950–1050°C), giving bronze an edge in high-heat and heavy-duty environments.

Key insight: In the brass vs bronze vs copper debate, bronze families often win in seawater and bearing contexts, while brasses excel in forming, decorative, and cost-sensitive uses. Always match the alloy to your environment and fabrication needs for optimal performance and durability.

Now that you’ve seen the side-by-side comparison, you’re ready to choose the best alloy for your next project. Up next: a practical decision path and buyer checklist to help you finalize your selection and move confidently from specification to sourcing.

Making the Right Brass or Bronze Choice

Pick by Environment: Where Each Alloy Excels

Still debating between brass or bronze for your next project? Let’s simplify the decision process. Imagine you’re specifying parts for marine hardware, deep-drawn housings, or outdoor structures—each environment demands a different approach. Here’s how to match alloy to application, so you never have to wonder “is brass the same as bronze” or “are brass and bronze the same” again:

- Define Your Environment: Will your part face seawater, freshwater, indoor air, or outdoor weather? For harsh marine or corrosive settings, bronze families (like phosphor bronze or aluminum bronze) are your safest bet. For moderate marine exposure, naval brass is a solid performer. For indoor or decorative uses, brass is often the most practical choice.

- Assess Mechanical Needs: Does your application require high strength, wear resistance, or springiness? Bearings, gears, and moving parts benefit from bronze, while decorative trims or electrical connectors might be best served by brass components.

- Choose Fabrication Method: Are you forming, machining, or joining? Cartridge brass excels in deep drawing and forming. Bronze alloys, though harder, are preferred for machined parts that must endure friction or load. If you’re unsure how to tell the difference between bronze and brass during fabrication, check color, density, and machinability.

- Specify Finishes and Compliance: Do you need a bright finish, a natural patina, or certification to standards? Each alloy responds differently to finishing and may require specific documentation for quality and regulatory compliance.

Pick by Fabrication Method: Matching Process to Material

- CNC Machining: Use bronze for complex, high-precision, or high-wear parts. Brass is ideal for rapid machining and intricate decorative details.

- Deep Drawing/Forming: Cartridge brass sheet is the top pick, thanks to its ductility and bright color.

- Welding/Brazing: Both alloys can be joined, but verify the specific grade’s compatibility and required filler metals.

When to Choose Custom CNC: Accelerate Results with Expert Support

If your project demands tight tolerances, intricate geometries, or rapid prototyping—especially with bronze or precision brass components—partnering with a specialized CNC shop can save time and risk. XTJ’s CNC machining services deliver production-ready parts from your chosen alloy, with ISO 9001:2015 and IATF16949-certified quality, advanced 4/5-axis machining, and engineering support to help you optimize material selection and design for manufacturability.

| Buyer Checklist: What to Request from Suppliers |

|---|

|

Remember, is brass a metal? Absolutely—it’s a copper alloy, just like bronze. But the best results come from matching alloy to application, not just picking by name. And if you’re ever unsure about what is made of bronze or how to tell the difference between bronze and brass in a finished part, consult your supplier or request a material certificate for peace of mind.

Ready to move from specification to sourcing? Choose your alloy, clarify your requirements, and partner with trusted experts for fabrication—so your next project performs as beautifully as it looks.

Brass vs Bronze: Frequently Asked Questions

1. What is the main difference between brass and bronze?

Brass is primarily a copper-zinc alloy, known for its bright yellow color and excellent formability, making it ideal for decorative and deep-drawn parts. Bronze, on the other hand, is mainly a copper-tin alloy, sometimes with elements like aluminum or phosphorus, offering higher strength, wear resistance, and superior corrosion protection, especially in marine and bearing applications.

2. How can I tell if a part is made of brass or bronze?

To distinguish brass from bronze, check the color—brass is usually bright yellow or gold, while bronze is reddish-brown. Both are non-magnetic and produce minimal sparks if ground. For a definitive answer, use a chemical spot test (with proper safety gear) or an XRF analyzer to identify the exact alloy composition.

3. Which is better for marine environments: brass or bronze?

Bronze is generally better for marine environments due to its superior resistance to corrosion from saltwater. Silicon bronze and aluminum bronze are especially recommended for underwater or high-risk marine hardware, while naval brass is suitable for moderate marine exposure but may be vulnerable in hot or acidic conditions.

4. Is brass or bronze easier to machine or form?

Brass is easier to machine and form, making it the top choice for deep drawing, spinning, and decorative parts. Bronze is harder and more wear-resistant, making it ideal for precision CNC machining of bearings, gears, and components that require tight tolerances and durability.

5. What are typical applications for brass and bronze alloys?

Brass is commonly used for electrical connectors, decorative trim, musical instruments, and plumbing fittings. Bronze is preferred for bearings, bushings, marine hardware, springs, and fasteners where strength, fatigue resistance, and corrosion protection are critical.

-

Posted in

alloy comparison, brass vs bronze, corrosion resistance, machining brass and bronze, marine hardware materials